Schedule a Call Back

Adoption of advanced manufacturing technologies is imperative: Khushboo Doshi

Articles

Articles- Nov 29,24

Related Stories

Gandhi Automation’s sectional overhead doors provide unrivalled safety

Their robustness and energy-efficient features make them a smart investment, ensuring both operational effectiveness and financial benefits over time.

Read more

The machine tool sector is growing with rise in automation: Hrishikesh B Sawant

The Indian machine tool industry is currently growing, with a number of factors contributing to its expansion.

Read more

Greaves Engineering is steadily increasing exports: Dr Arup Basu

In this interview with Rakesh Rao, Dr Arup Basu, MD, Greaves Cotton Ltd, highlights emerging trends in the Indian manufacturing sector and the company's plans for robust growth with minimum carbon f..

Read moreRelated Products

Fire Alarm

Safe Zone is prominent traders and suppliers of the industry, offering a wide range of wireless fire alarm.

Read more

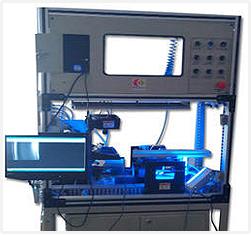

Sorting Automation Systems

Renovus Vision Automation offers sorting automation systems.

Read more

Manual Bagging System

Alligator

Automations provides a wide range of manual bagging systems.