Schedule a Call Back

Surface Modification Technologies aims for global expansion: Dr Umesh Mhatre

Interviews

Interviews- Jan 13,25

Related Stories

India Advances Battery Recycling with Standards, Traceability and Eco-Design

India’s battery recycling sector is entering a decisive phase, driven by policy incentives, shifting chemistries, and rising demand for circular manufacturing to support the country’s clean ener..

Read more

Vipul Organics Automotive Organic Intermediates Exports Cross Rs 40 Million

Cumulative exports of this high value speciality intermediate have now crossed Rs 40 million, marking a strong and steady scale-up in global demand.

Read more

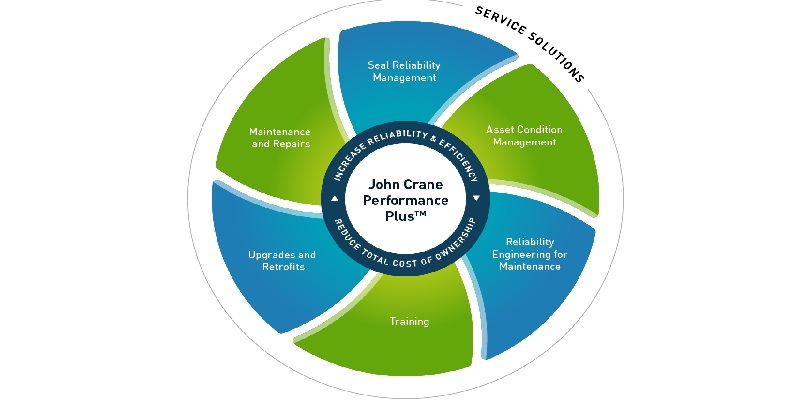

John Crane launches Performance Plus to drive a new era of operational excellence

The framework combines data-driven monitoring, expert consultancy and hands-on training to help customers reduce downtime, boost reliability and strengthen long-term resilience.

Read moreRelated Products

Precision Cutting Tools1

S S Trading Corporation offers a wide range of precision

cutting tools.

Slotting Head Unit for All Cnc Turn Mill Centers

Sphoorti Machine Tools Pvt Ltd offers a wide range of

slotting head unit for all CNC turn mill centers.

Slotted Tool Disc and Tool Holders

Prominent Machine Tools offers a wide range of slotted tool disc and tool holders.