Schedule a Call Back

Seco R&D delivers for Scania

Articles

Articles- Oct 30,23

Related Stories

India is a key strategic market for Hexagon: Jason Walker

In this interaction with Rakesh Rao, Jason Walker, VP, General Manufacturing Practice Lead, Hexagon, sheds light on the factories of the future and importance of India for Hexagon.

Read more

Automation is reshaping laser design with AI and ML: Hrishikesh Sawant

Laser integration with traditional or CNC machine tools significantly enhances precision, speed, and cost-efficiency by enabling precise cutting, welding, and surface treatment processes, comments H..

Read more

Kollmorgen introduces new high-voltage IC Ironcore DDL motor

A key benefit of the IC Ironcore DDL motor is that it enables OEMs to serve global markets without significantly redesigning their machines for each region.

Read moreRelated Products

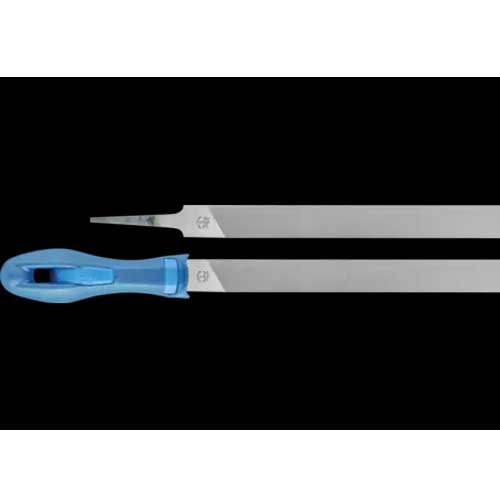

Turning Tools

Duracarb Cutting Tools offers a wide range of Turning

Tools.

Carbide Burrs

SRT Industrial Tools & Equipments offers a wide range of carbide burrs.

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.