Schedule a Call Back

Beckhoff offers solutions for enabling Industry 4.0

Interviews

Interviews- Jan 01,18

Related Stories

Addverb to enter humanoid robotics with next-gen humanoid in 2025

The new humanoid robot will be an advanced AI agent capable of processing vast volumes of multi-modal data from vision, audio, and touch inputs.

Read more

Honeywell to sell PPE business to Protective Industrial Products for USD 1.32 bn

The PPE business has approximately 5,000 employees and a streamlined global manufacturing and distribution footprint that allows for cost-effective production, close proximity to customers and optim..

Read more

Redefine operations with Gandhi Automations' dock leveller solutions

Designed to meet EN 1398 standards the levellers are engineered for the most demanding environments.

Read moreRelated Products

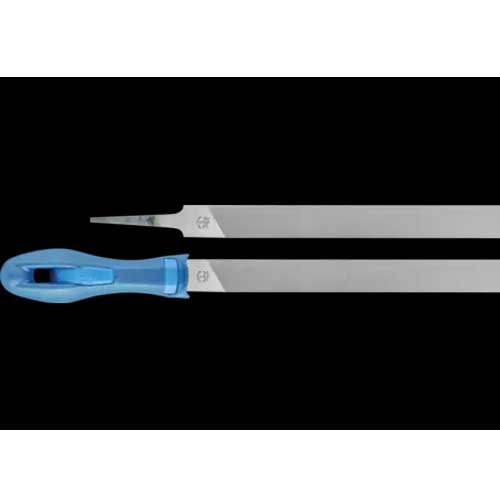

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.

Ss Hex Head Bolts

Trychem Metal And Alloys is offering SS hex head bolt.

Cutting Tools

Get Cutting Tools provides a wide range of CNC cutting tools