Schedule a Call Back

"Training is very in safety services, especially hazardous H2S situations"

Interviews

Interviews- Dec 02,14

The SPA Group, established in 1986, is a pioneer in oilfield services in India. Started with an objective to provide dependable and innovative solutions to the oil and gas industry, SPA Group has build a diverse portfolio of services that span H2S (hydrogen sulphide) safety making it the first Indian company in the field of H2S Safety Services, Oilfield safety training programs, inspection, maintenance and repairing of equipments, calibration of life-saving equipments like gas detection systems, breathing systems, respiratory equipments, etc. A gold medallist in mechanical engineering, Mr Surendra Mohnot, Chairman, SPA Group, started his career with a Kolkata based firm where he contributed in setting up a railway and automobile coil springs manufacturing unit in Nagpur and followed it with several other assignments with various companies, highly benefiting from his expertise and association with them, before succumbing to the entrepreneurial bug. Excerpts from an interview with IPF...

What inspired you to start this line of business after such diverse experience? What was the spark?

The Oil and Gas Industry always intrigued me. There were friends visiting us en route to offshore oilfields of ONGC and returning from there. Sometimes they brought along some spares, which were imported at exorbitant prices. I asked them, "What are those?" and I found very interesting H2S gas ampoules, which were then manufactured by just a couple of companies in the world. I said what do you do with these ampoules in the oil field and a discussion ensued, which continued almost the whole night with these friends from the oilfields sector. This gave me an idea of H2S Safety technology and how this can be developed in our country covering services, products, training, etc.

SPA is a pioneer in its field. What were the hurdles and hindrances in the initial years?

When I started talking about H2S Safety Services (our entry door to the oil and gas industry in India), believe me I had nothing to offer. My kitchen laboratory became active and I started burning the midnight oil. After weeks of trials I could make the first indigenous H2S ampoules, which I offered my friends free of cost to try out in the field, and hey presto, I had a client here agreeing to try out our products. Gradually I assembled a team of experts who had worked in the Oil and Gas sector in the Middle East, and we were trying to start training programmes in H2S safety and thereby the juggernaut of our business started rolling. Soon we had willing clients asking more.

Until we started making our clients and their employees aware of hazards of working in oilfields in general and H2S safety in particular they could never imagine that this could pose a life-threatening situation on the oilfield installations. They also asked us if we could supply them all the equipment to make our operations safe against these hazards of H2S. International competition bidding was called for and we went on winning for more than two decades against stiff international competition, in the process becoming pioneers in this industry.

What are the changes witnessed during this period?

There has been a quantum shift in the approach of our clientele and we have made them aware that without these safety aspects in place their operations could suffer heavy losses and as such they are very willing to come to us and ask for our support in making their personnel and equipment safe to handle any eventual situation in so far as hydrogen sulphide leakage hazards are concerned. This has given us new clients thanks to the word of mouth publicity, as that is how they heard about us, and found these products being available locally and economically served their purpose excellently.

What is the scope of products and services offered?

During this period, as a foresight, we set up a one-stop analytical testing and R&D laboratory within the group. With this new arm, we started doing research on environmentally responsible, eco-friendly, safe-to-use products for industrial applications. We also simultaneously developed products for home care and personal care sectors. These being fast moving consumption goods, we faced a lot of hurdles in educating the end customers. We had to not only provide innovative products, but also be seen as different and unique from the run-of-the-mill product manufacturers who have crowded the market with the products that are just opposite to what we want to offer the consumers. Once we win over the consumers, we surely have the edge over any other competitor and find markets for these products.

What is the nature of the training and inspection services?

Our Hydrogen Sulphide Safety philosophy depends on our highly acclaimed '3T' approach of Training, Technique & Technology. Training is a very important aspect of these safety services as people who are faced with hazardous H2S situations should exactly know how they have to act in any eventuality through regular and rigorous trainings onsite or at our training centre, where we can equip the participants with knowledge to save themselves, others and the operations. The safety equipment which are detection and protection type have to be regularly inspected to ensure these are perfectly serviceable hence timely inspection and particularly at the time of any special event for example, production testing at rig, confined space entry, etc., have to be carried out to ensure proper operation of this equipment.

Safety is paramount in this segment, but one often is witness to acts of negligence. Are there built-in safety measures that are fool proof?

There cannot be any built-in safety for one's life. Hence we warn all the personnel we train that they have to be very alert and should not be negligent and should always follow rules as it concerns their own life. We firmly imbibe in their minds that any operation can run smoothly when the operator himself is there to do the act. H2S being nicknamed as "silent killer", the very thought of H2S must instil a sense of fear in the minds of people so that at least for their own sake they will attentively learn what is being taught to them. This basis of safety training and safety working practices are taught to all personnel.

How about extending the services to other, less hazardous sectors?

The expertise acquired for providing safety services to the oilfields can easily be adopted for other sectors like Confined Safety Entry in the chemical/petrochemical industries and municipal/sewage sectors, marine industry, cement industry, mines, etc.

What are the manufacturing facilities? What type of products?

We have a pilot plant manufacturing facility for test marketing of various products and as and when products are required by the market, commensurate facility will be created at appropriate locations.

What about the export potential?

There is good scope for environmentally responsible products. Discussions are currently going on with our prospective markets and end users for these products.

What are the future opportunities and future plans?

We want to increase our market share within India and neighbouring countries by aggressively marketing our various services.

Related Products

Fieldpower Power Bus System

Weidmueller Electronics India offers FieldPower power bus system.

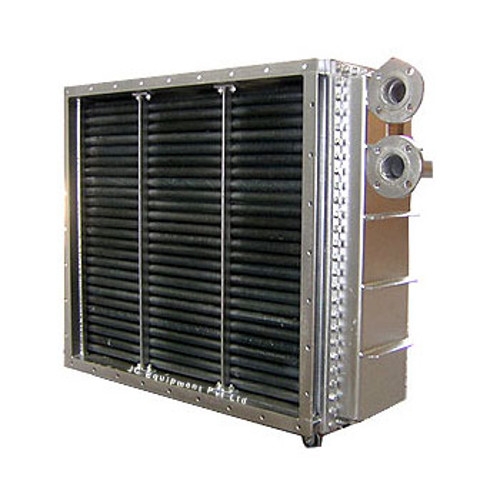

Finned Tube Heat Exchanger

Simon Coil And Heat Exchanger manufacturers

finned tube heat exchangers.

Ceramic Reinforced Grinding Wheels

Rüggeberg GmbH & Co KG,

PFERD-Werkzeuge, has launched new reinforced grinding wheels with ceramic oxide

grain.