Schedule a Call Back

The future of automobiles begins in production: Cornelia Gewiehs

Industry News

Industry News- Apr 16,25

How can process data from automobile

production be recorded and used to increase energy and resource efficiency in

production? What influence does the component quality of gearing elements such

as drive shafts and axle drives have on noise generation in electric cars?

Which grinding tools can be used to machine new materials and steels that are

difficult to machine?

For 50 years now, the search for the

most efficient machines, tools and systems has attracted trade visitors and

experts from vehicle manufacturing and supplier companies to EMO Hannover, the

world's leading trade fair for production technology. The transformation of the

automotive industry – the second largest customer for machine tools – is

changing the focus of the EMO. Topics such as automation, digitalisation and

artificial intelligence mark the development. New drive concepts are raising

questions as to whether the focus should be on the production of mechanical

components for electric cars or compressor and motor shafts for fuel cells. Industry

solutions for the circular economy or battery recycling are moving into focus

because the regulatory framework is changing drastically. And the challenge

above all else is to be as efficient and flexible as possible in order to be

able to respond quickly to customer requests.

Efficient automobile factories for

greater competitiveness

"Modern machine tools and

innovative production systems are essential for building efficient, flexible

and resilient factories," stresses Dr

Markus Heering, Managing Director, EMO organiser VDW (Verein Deutscher

Werkzeugmaschinenfabriken – German Machine Tool Builders' Association). The

trade fair concept is currently being presented on an international stage at

the EMO World Tour. Under the motto "Innovate Manufacturing", EMO

stands for innovation, internationality, inspiration and the future of

metalworking. At the same time, Heering underlines the trade fair's expertise

in industry solutions: "The machine tool industry is always in close

contact with vehicle manufacturing companies," he says.

In fierce international competition,

especially with Chinese car manufacturers, the focus is on design, features,

quality and costs. In order to assert themselves here, the modernisation of

factories is a pressing concern for both OEMs and medium-sized supplier

companies. The modern factory features end-to-end process automation, precisely

coordinated interfaces and integrated digitalisation solutions. Machine tool

manufacturers have come up with a solution and are equipping machines with

extensive sensor and monitoring systems ex works. They provide the basis for

data collection and analysis. The aim is to make it easier for customers to get

started with data-driven production technologies in which processes can be

visualised and optimised.

Digitalisation is not an end in itself,

emphasised Dr Milan Nedeljkovi?,

Member of the Board of Management responsible for production at BMW AG, in

a recent interview. Rather, it is an important enabler. The trend is towards

integrated machine systems that can be used to manufacture comparatively small

quantities in the powertrain area of electric cars just as economically,

efficiently and reliably as mass products. The wide range of equipment variants

and design features with which vehicle manufacturers want to incentivise buyers

also require flexible production solutions.

Automation in a modular system

EMO Hannover 2025 picks up on such

trends, for example with a wide range of automation solutions that can be

implemented successively and also in conjunction with existing machines.

Automation extends from simple solutions such as pallet changers and handling

systems through to the use of robots and autonomous factories with self-driving

systems. Secondary processes such as cleaning, labeling and measuring can be

integrated. At the Cobot Area joint stand, for example, the focus will be on

collaborative robots and their potential applications.

In order to support and relieve machine

operators, assistance systems will be presented in which artificial

intelligence can also be used. AI solutions can also be used for predictive

maintenance and adaptive process management. The AI + Digitalisation Area joint

stand offers visitors from the automotive industry the opportunity to find out

more about best practice examples.

Sustainability along the supply chain

The automotive industry is intensively

discussing how energy and material consumption can be reduced in production.

This was also demonstrated recently at the VDA (German Association of the

Automotive Industry) Mobility Innovation Summit in Berlin. According to the EMO

organiser VDW, investments in new machines already pay off, with energy savings

of 25%. However, other levers can also be identified to make production

processes more efficient and reduce carbon emissions. The Sustainability Area

at EMO 2025 is a meeting place to discover modern solutions for sustainable

production. Material efficiency plays a major role. With new simulation methods

in component development and innovative production processes, for example,

components can be designed to be even more resilient and durable.

The recyclability of vehicles must be ensured by taking recycling into account when developing new vehicle components. According to the VDA, around 85% of a vehicle is currently recyclable. Around a third of a new vehicle is made of secondary material. In order to further increase these quotas, a functioning circular economy must be set up in which all stakeholders work closely together and share their data. This involves production and material supply chains for several thousand components and parts that are installed in every vehicle. With regard to electromobility in particular, it is important to reuse batteries and recover lithium, nickel and cobalt for new batteries. These examples demonstrate the importance of close cooperation between development, production and vehicle construction. EMO Hannover 2025 is the best platform for cross-technology and cross-company discussions.

-----------------------------------------------------------------------------------------------------------------------

Author: Cornelia Gewiehs

Related Stories

Tata Motors inaugurates advanced vehicle scrapping facility in Kolkata

Equipped with cell-type dismantling for commercial vehicles, two-wheelers and three-wheelers, and line-type dismantling for passenger vehicles, there are dedicated stations for the safe dismantling ..

Read more

Aerem Solutions and OMC Power partner to finance solar rooftop adoption by MSMEs

Under this agreement, Aerem through its NBFC, will enable credit facilities of Rs 2 billion to OMC Power’s customers, enabling MSMEs to invest in energy-efficient solar systems with easy financing..

Read more

Exide Industries in battery talks with EV makers

Hyundai is set to become the first Indian automaker to use locally manufactured battery cells for electric vehicles through its agreement with Exide’s subsidiary, Exide Energy Solutions, signed in..

Read moreRelated Products

Turning Tools

Duracarb Cutting Tools offers a wide range of Turning

Tools.

Carbide Burrs

SRT Industrial Tools & Equipments offers a wide range of carbide burrs.

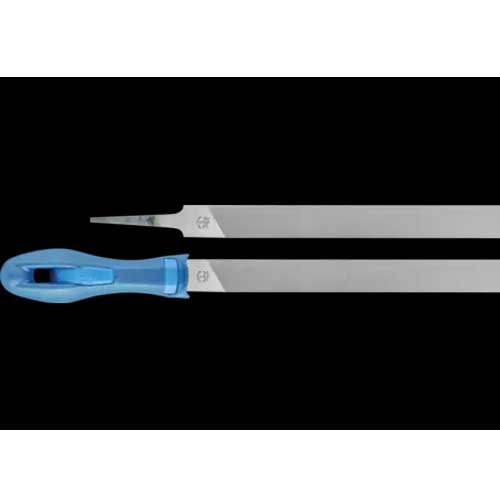

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.