Schedule a Call Back

Technology integration should be human centric, not product centric

Interviews

Interviews- Feb 15,23

Kindly brief us about your company.

Arcraft might not need an introduction when it comes to metal welding, metal cutting and metal surface treatment by metallurgy. With glorious track record, Arcraft has emerged as company with innovations and challenges either refused by Indian companies or fulfilled by overseas brands. From humble beginning of plasma cutting machines, we have ventured into welding, surface metallurgy and automation. Metal destruction, preparation and construction may seem bit confusing but Arcraft has proved its mettle in spectrum of applications with few firsts’ like 150 mm plasma cutting, 0.1 mm micro plasma welding, 25 mm ID cladding which are all related to metal but in different application zones altogether. Bringing them under one roof is a success story of Arcraft. From Aerospace to Zeolites, there is hardly any sector Arcraft has not served.

What is the USP of your company? How do you contribute to the growth of the Indian manufacturing sector?

We believe in ‘Value not Volume’ and ‘Solution not Supplier’. As matter of survival many in the field are simply importing, repacking and pasting their names on the product. This is not growth but only commerce in true sense. We have emerged as truly technologically strong team who believe in ‘Explication’. The term ‘State of the Art Technology’ has become so common that it has lost its meaning. With world as global village, technology is available for any one. But time, trust, honesty and loyalty are very important factors of business which are part of human behavior and not technology. Welding and its allied businesses are not part of India’s prominent business sectors. The annual revenue generation of welding field may not be as big as a single small cap company. It is high time that all the prominent players in the field to come together under one umbrella and represent this field as of national importance. Only then we can really talk of our contribution in the growth of manufacturing sector in India.

What is the contribution of exports to your business? How do you intend to expand your exports?

‘Make in India’ has always been our motto from time of inception. With zero export for the first few years, now recognised for technical exports, we have presence in every continent. Presently we are averaging at about 30 to 35 per cent export of our capacity.

Could you please share with us information about your new innovations or products and solutions that you have launched in 2022?

Innovation is a practice within at Arcraft and not just a term. Every year we have introduced new development in the field of metal cutting, joining, rebuilding, and reclaiming for past 15 years. Import substitute is our passion. Improvisation, up-gradation, reliability, and dependability of our products and services are ingrained in our work culture.

How important is branding for your products and solutions? What are your marketing plans for 2023?

We do not follow the competitors and avoid making the mistake what the competitor is doing. Our brand is for volume. ‘Also Ran’ attitude to flood the market is making the products cheaper not competitive. While in the race to make the product affordable what suffers is quality, standards, service and finally trust of the customer. With wide choice of low cost products and mentally prepared customers for ‘Use and Throw’, volume business is not for Arcraft. We aim to develop technically sound and long lasting products. Our branding is to remain price competitive without compromising standards. Innovations, was, is and will be our passion. This passion is our permanent plan every year to come.

According to you, what is the mantra for success in the marketplace?

‘Achieve, maintain and sustain individuality and success will follow you’. Research and development is the last department in Indian manufacturing sector. Best of the Indian brains, working for topmost foreign brands is our pride. It is time we come out of this mind set and focus more on ‘Invented in India’. With uncountable examples of ancient science and the legacy, India has lot to offer to the industry. Where we fail is commitment. The mantra to the success is ‘Inclusiveness’. Let the product speak for itself.

What are emerging trends in your industry?

It is not so encouraging. Rampart product certifications without justified standards have brought down the product quality to rock bottom. Looking at East as world’s manufacturing hub has affected who’s who in the field and has dented the business model to the extent that large section of unorganised players are simply dumping substandard goods. It is going to prove disastrous if immediate steps are not taken and stringent standards are not enforced. Fly by night operators are not only spoiling the market but duplication of quality products has become common term. The emerging trend must enforce and implement strict laws to bring welding field from subcategory to the recognised one.

Sustainability is gaining traction in the industry. How is your company gearing up for sustainability?

No one is indispensable in this world. Sustainability is time bound. Nothing is permanent. There was a saying once ‘What happens to Ford happens to US’. Today where is Ford? Industrialisation which may be just 150 years old has seen many companies came and gone or changed hands. Many sectors were once ruling the industry, are nowhere to be seen now. With fast growing technology, vicious grip of digitisation has not left any sector untouched or without interference of software. Welding field is no exception to this. Humans are being treated as machines. Wellbeing of workforce is last word in the businesses. Work life balance has suffered. Arcraft always attempts, is to keep the workforce healthy and happy. We appreciate talent and hard work, sustain good product, workforce, and good company.

It is said that to improve competitiveness, it is important to adopt modern manufacturing technologies (like automation, robots/cobots, digital tools, AI, Industry 4.0, 3D printing, etc). What is your take on this?

We get many videos showing automation especially robots working in manufacturing sector, But has anyone ever come across a robot manufacturing unit where robots are making themselves? There is no alternative to modern technology. But is it Green? Automation has not relaxed anyone but it is insane pressure to perform. Computers replaced typewriters at one point and eased typist’s life. But now it is haunting everybody’s life for the race of performance against time. Technology integration should be human centric not product centric.

SMEs are the backbone of India's manufacturing sector. How can we help SMEs to increase their productivity and efficiency? What are your suggestions to the government to make SMEs stronger?

Taxes are unsigned partners in the business. To the extent that business is selling taxes not products. The backbone has permanent spondylitis of lengthy procedures and never ending demand of justification of honesty. Taxes and axes go together for the honest businesses. No doubt, taxes are major source of income to any government. However, taxes at multiple levels and complicated procedures need to be simplified. SMEs are engineering companies. They should be allowed to work freely on engineering products. Presently, almost 20 per cent of productive time has to be given to maintain tax records, licenses with the fear that, however perfect the records are, with too many laws and clauses every SME is bound to get caught in some mistake or the other. Simplification, compliances process, awareness and education on policies, taxes, laws have to be imparted on the SMEs through Industrial Associations, Institutes of finance related professionals, and ministries.

The government is aiming to make India a $5 trillion economy. What is your vision for the Indian manufacturing sector for 2025?

India is not a poor country but poorly managed country. In spite of share of almost 10 per cent in GDP, India’s CAGR is in ‘C’ category. Our import is 20 per cent higher than exports with almost a gap of $100 billion. Then how do we have our foreign reserves at approximately $550 billion. This is investors’ money. India has to overcome its dependency on investors for foreign reserves and must thrive to make trade policies, infrastructure and quality standards such that we earn from exports. Why do we have compulsion to trade in US dollar even with our Asian neighbours? Look at EU, more than 25 countries came together to form single currency. India must emphasis at the world economic platform that at least the cross border trade to be done in local currencies. Respect to the currency is respect to the country. $5 Trillion economy, is a very honest aim and easily possible target for country like India.

What are your long term goals for your company?

Success is easy to achiever but difficult to maintain. Maintaining the current dominant position in our field is our first priority. Give our team of talents and skilled workforce a perfect work-life balance and growth they deserve. We will surely have targets to achieve but we shall never target our team and enforce excessive pressure on them. We will keep investing ourselves to maintain our brand as a time, trust, honesty and loyalty.

Related Stories

Indian machine tools sector is poised for strong expansion: Rajesh Mandlik

During the recent press meet in Mumbai for IMTEX Forming 2026 (which will be held from January 21–25 in Bengaluru), Rajesh Mandlik, CEO of Setco Spindles India, discusses with Rakesh Rao growth op..

Read more

Enhancing metal cutting with IoT connectivity

IoT-enabled metal-cutting machines can dynamically adjust spindle speeds, coolant flow rates, and feed rates based on real-time feedback. This level of automation minimises human error and enhances ..

Read more

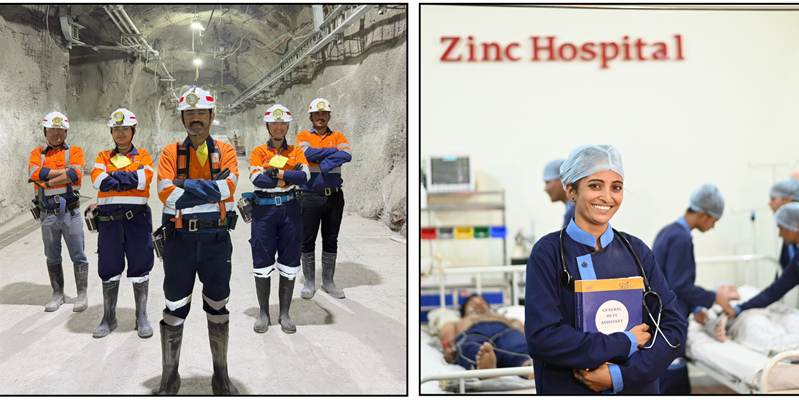

Hindustan Zinc reaffirms commitment to youth empowerment on National Youth Day

Hindustan Zinc’s skill development based social impact initiative has successfully trained nearly 8,000 rural youth by equipping them with market-relevant skills.

Read moreRelated Products

Hardy - Chassis Mounted Weighing Card for Rockwell PLCs

Kore Mechatronics Private Limited offers a wide range of

hardy - chassis mounted weighing card for Rockwell PLCs.

Tack Welding Machine

Invent Weld

Automation offers a wide series of tack welding machines.

Bench Welding Positioner

Toss Weldtronics

offers a wide range of bench welding positioners.