Schedule a Call Back

Syrma SGS is well-positioned to leverage industrial shifts: J S Gujral

Articles

Articles- Mar 07,25

Related Stories

PLI schemes have had a major impact on several Indian sectors: Abhishek Malik

By encouraging domestic manufacturing, these programs have raised output, created jobs, and increased exports. Additionally, they have drawn large investments from both domestic and international fi..

Read more

Goa’s first electronics manufacturing cluster nears completion

Spanning over 597,000 square metres near the Goa-Mumbai National Highway, the EMC will offer various incentives to incoming companies through support from both the state government and the Ministry ..

Read more

Dixon to manufacture Alcatel smartphones in India

This deal adds to Dixon’s recent expansion moves. In April 2025, the company formed a 60:40 joint venture with Taiwan’s Inventec to manufacture IT hardware, and a 50:50 joint venture with Signif..

Read moreRelated Products

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.

“Kusam-Keco” Partial Discharge Acoustic Imager - Model - Km-pdai

‘Kusam-Meco’ has introduced a new “Partial Discharge Acoustic Imager Model KM-PDAI.

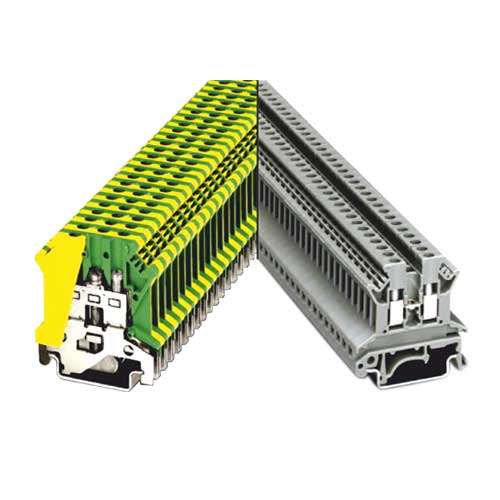

78 Series Din Rail Terminal Blocks

Werner Electric Private Limited offers a wide range of 78 series din rail terminal blocks.