Schedule a Call Back

Shriram Axiall Joint Venture is to Avail World-Class Technology

Interviews

Interviews- Sep 04,15

Gurgaon-based DCM Shriram Group has entered into a joint venture agreement with US' company Axiall to usher global technology and processes in the vinyl market. In this interview, Rajiv Arora, Business Head, Shriram Axiall P Limited, elaborates about the company's growth strategies and product portfolio. Excerpts...

Shriram Axiall has an installed production capacity of 35,000 MT per annum for customised vinyl compounds consisting of various compounding techniques such as Buss, Banbury, continuous mixers, twin-screw extruders and high-speed and slow-speed ribbon blenders. The process is monitored through the latest PLC systems and other advanced controls. Vinyl resin, which is available from the resin plant of DCM Shriram, gives an added advantage in customising the compound. Excerpts from the interview:

Could you provide us a history about the company and its operations in India?

Shriram Axiall, formerly known as Shriram Polytech, is one of the largest organised players for PVC compounds in India and has been in the business for almost five decades. Evolving along with its consumers and their needs over time, what started 50 years ago with footwear and wire and cable segments has steadily graduated to value-added segments like flame retardant, flame retardant low-smoke and heat-resistant cable compounds, automotive, food and medical, colours, and now, speciality compounds. The company has a manufacturing facility at Kota in Rajasthan that was established in 1964. Today, it ranks amongst one of the most advanced plants in the country.

A wide portfolio of vinyl compounds manufactured here meets the performance requirements of a broad range of industries. The thrust at Shriram Axiall is to provide customised solutions for specific industry segment requirements. Apart from catering to the domestic market, these vinyl compounds and colour concentrates are exported to various geographies in the world. Shriram Axiall believes strongly in achieving excellence through people. Our continuous training and development programme further enhances the capabilities of the highly professional workforce. Shriram PolyTech entered into a joint venture with Axiall Corporation in April 2014 for spearheading new applications, products and markets.

What is the company's product portfolio?

Shriram Axiall is one of the largest organised players for PVC compounds in India and today ranks amongst one of the most advanced plants in the country with its house wiring, signalling cables, power cables, control cables, appliance plugs, power wires, telecom wires, appliance panels, control boxes and enclosures. We are geared to explore new markets, diversify our product portfolio, and extend the range of applications through the above mentioned joint venture.

What is the importance of PVC compounds when it comes to heat-resistance and fire-resistance properties of wires and cables?

PVC is inherently flame-retardant due to the presence of chlorine. Hence it finds high acceptability in applications where self-extinguishing properties are required. In both rigid and flexible applications PVC is a good fit where flame-retardant properties are required. Though PVC is not very suitable for high heat applications, recent technological developments have made it possible for PVC to be designed for high performance applications. To showcase this technology we supply PVC compounds that can withstand temperatures up to 125 degrees Celsius and find applications in automobiles where high performance under high temperature is required.

What are the new technologies that the company has introduced in recent times in terms of manufacturing processes?

The Shriram Axiall joint venture was signed to avail world-class technology from Axiall to bring in new possibilities in the Indian vinyl marketplace. Shriram Axiall has a state-of-art R&D facility. It is equipped with world-class equipment which allows us to innovate continuously and deliver value to our customers. Wire and cable-related products are slated to be taken in a big way in coming times although we have not hit upon wire and cable at the moment as the industry has not been doing so great in India. But we have been working at the backend doing things for improving products and becoming more efficient. We have been getting certifications for our products and facilities which allow us to cater to customers with global requirements.

How have these helped enhance the value of the products?

We plan to introduce products with Axiall's advanced technology and provide the Indian customers with options that have not been available before. We plan to work with standards' organisations and customers to upgrade them to be in line with the global norms. Since the demand for wire and cables is directly linked to GDP growth, with the current government enjoying a clear majority, the market sentiments are improving and hence on the demand front the scenario looks better as compared to the previous years.

Could you provide details about your manufacturing facilities, especially the one at Kota?

As mentioned before, we are one of the largest organised players in Indian vinyl compounding. We have an installed capacity of 35,000 MT per annum. Out of this capacity, 5,000 MT was recently added after our JV with Axiall Corporation. Our company is certified by DNV for ISO 9001, ISO 14001 and OHSAS 18001. We use vinyl resin sourced from DCM Shriram's integrated plant which gives flexibility to our operations. Our compounding process is controlled through advanced PLC systems. We have a fully automated packaging line which leaves no space for variation. Shriram Axiall has always been a pioneer for innovation. Our aim has been to upgrade our facility to global standards. We plan to have our whole facility ROHS-compliant keeping in mind the needs of our customers.

What kind of R&D is the company engaged in and how will this enhance the value of the products?

Shriram Axiall has a state-of-art R&D facility. It is equipped with world-class equipment that allows us to innovate continuously and deliver value to our customers. A lot of backend work is being done to improve our products.

Does the company also cater to the EHV segment?

No, Shriram Axiall is not into manufacturing compounds for EHV cables.

How will the government's policy to boost infrastructure development and housing for all benefit the company?

PVC is used extensively in infrastructure projects like metro rail, airports, housing, bridges, railways, etc. With the government's plan to ramp up infrastructure activity in India, PVC demand both in rigid and flexible space will get a big boost in the immediate and long-term future.

What are the company's expansion plans for the next couple of years? Will there be more capacity addition?

The company is geared to explore new markets, diversify the product portfolio, and extend the range of applications through this joint venture. We are looking at getting high temperature application PVC compounds. The other thing we are doing is high-speed applications which help the customers increase their productivity. Axiall already has a sustainable product range such as ASPIRE which is a big hit in the US' market, especially with automobile companies. Now, Shriram Axiall is quite keen on getting that product into the Indian market for automobile and wire and cable segments. We will also be promoting our thin wall extrusion compounds in the country which again are aimed at enhancing productivity by optimising material usages.

How big is the cable market in India and what is the company's market share?

The Indian wire and cable industry approximately stood at Rs 15,000 crore by the end of 2012 and presently stands at Rs 24,000 crore approximately. The industry is expected to grow at a compounded annual growth rate (CAGR) of 15 per cent in the coming future. Although the wire and cable industry in India is largely volume-driven, quality and technical parameters with reputed brands play a dynamic role in determining brands for various products. PVC, XLPE and PE constitute the majority of the total universe of materials used for wires and cables. XLPE is posting good growth in volumes as all power expansion projects are now using XLPE cables for EHV and MV applications. PVC, on the other hand, has remained the mainstay of the unorganised players, both suppliers and customers, and as a consequence, around 50 per cent of the wire and cable currently available in the market continues to be sourced from unorganised sector players with lacklustre focus on technical and quality support.

Shriram Axiall (P) Ltd., 2nd Floor, Plot No. 52, Sector 32, Institutional Area, Gurgaon, Haryana - 122 003. Tel.: 0124-4632112, Fax: 0124-4632199, Website: www.shriramaxiall.com.

Related Products

Fault Annunciator

Insys Electrical & Controls offers a wide range of fault annunciator.

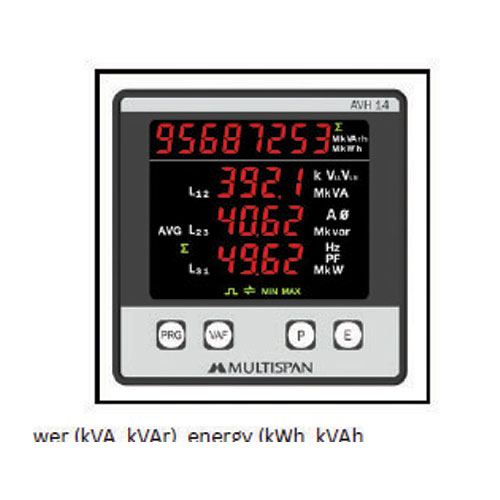

Multifunction Meter

Insys Electrical & Controls offers a wide range of multifunction meter.

Safcon Bolt Container Seals High Security Seal for Containers & Cargo

Safcon Seals Private Limted offers a wide range of safcon bolt container seals high security seal for containers & cargo.