Schedule a Call Back

"Our solutions can increase reliability and improve productivity"

Interviews

Interviews- Jun 06,14

Henkel Adhesive Technologies India (P) Ltd is a subsidiary of Henkel AG & Co KGaA, Germany. In India, Henkel is a market leader in adhesives, sealants and surface treatments for consumers, craftsmen and industrial applications. Headquartered in Mumbai, Henkel has a long tradition of a well-balanced portfolio of international, regional and local brands. Its adhesive products provide solutions for a whole spectrum, from manufacturing anaerobic adhesives, cyanoacrylate adhesives, silicone sealants, polymer composites, solvent-based, solvent-free to cold seal laminating adhesives used in the flexible packaging industry. Its solutions are used in diverse segments ranging from manufacturing, electronics, automotive, aerospace to biomedical industries. Excerpts from an interview with Pradhyumna Ingle, Business Director (General Industry), Henkel Adhesives Technologies India.

Which are the company's brands and how have you categorised your business interests in India?

Our well-known brands include Loctite, Teroson, Bonderite, Technomelt and Aquence. In India, under the Adhesive Technologies Division, there are three main areas of business interest: a) industrial adhesives that includes flexible packaging, graphic arts, consumer packaged goods, tissue and towels, shoes, tapes and labels, etc; b) general adhesives; and c) assembly line, facility maintenance and repair, and transportation and fleet maintenance and repair. Henkel is a key partner in the development, manufacture and maintenance of vehicles and transportation systems. Our high-performance adhesives and sealants help engineers design and build advanced lightweight constructions and help achieve such objectives as higher speeds and lower fuel consumption.

We are also in the aerospace sector, providing structural assembly and metal surface treatment solutions. Our structural assembly portfolio of products provides structural adhesives and resins for the fabrication of metal, composite and honeycomb structures. Further, under the beauty care division, Henkel has Schwarzkopf Professional and Indola Professional, which is part of the Henkel Group, Dusseldorf and one of the leading suppliers in the hairdressing business worldwide. Based on a professional partnership with the hairdresser, the focus is to provide innovative concepts and services, which match the needs of the international salon businesses.

In short, Henkel has a wide portfolio of adhesives, sealants and speciality coatings that have been specifically designed to meet the requirement of a large variety of industrial needs. These products are a technology advanced replacement for conventional methods of bonding, sealing, and surface protection. Our products meet the design requirements, provide better performance, increase reliability, and are more cost-effective. The application areas include thread-locking, thread-sealing, retaining, gasketing, bonding, instant bonding, flexible bonding, protective coatings, lubricating, potting and encapsulating, floor coating, mould release, dispensing solutions, etc.

What is the USP of these products vis-?-vis those of the competitors?

We are the global pioneers in adhesive technologies. We are the first to come up with anaerobic technology. Our products are known for their quality and performance and consistency. We globally have ten R&D centres to continuously innovate solutions to typical industrial assembly and maintenance issues with capability to partner from the design stage.

Could you share some production details?

We have a state-of-the-art manufacturing set-up in India with plants at six different locations. If need be, we also leverage our global manufacturing network in order to provide our customers with access to the latest Henkel innovations.

Who are your major clients?

We work with the industry leaders in all segments like Suzlon, Reliance and many of the automobile giants in the vehicle repair and maintenance market.

How has been the company's global performance?

Globally, we put in a strong performance in a very challenging environment for business. We achieved solid organic sales growth of 3.5 per cent along with strong growth in operating profit and EBIT margins. However, our sales were impacted by adverse foreign currency exchange rates.

What is the targeted turnover for the India market?

Globally, we have set a target of Euro 20 billion in sales by 2016, out of which we want Euro 10 billion to be from the emerging markets. As one of the key emerging markets, we have a big role to play to achieve this goal.

Is India an export hub too?

We have exports to Sri Lanka and Bangladesh. Other than this, we do not have any exports as all the products manufactured at our plants are sold within India.

What are your expansion plans for the next 3-5 years?

In line with our global growth targets, we want to grow our sales, expand our manufacturing capacity by introducing new lines of innovative products, and implement business practices developed specifically for the Indian market. We are also focused on new markets like lighting, agriculture and construction equipments, and appliances, among others.

What is the company's R&D strategy for the India market?

We recently inaugurated our first innovation centre at Pune. The launch marks our most important investment in the region and further strengthens our focus on emerging markets. The centre will be important for developing innovative technologies and solutions that will cater to customers across South Asia, Middle East and Africa. The centre at Pune is designed to become a one-stop solution provider to our strong customer base in the region. A dedicated team of product and application experts at the centre will be devising adhesive solutions; optimal application procedures; and demonstrate assemble performance under simulated work conditions.

The centre is equipped with customer component testing facilities, dispensing systems, application training, product development and engineering facilities which will provide customers with comprehensive adhesive solutions. We have already launched four new products designed for the Indian market and two products under the brand Loctite were launched globally. Henkel's global spends on innovation, research and development amounts to Euro 414 million. The new Henkel India innovation centre caters to over 800+ automotive suppliers and metal customers as well as 26 OEM customers.

What about the development of new markets and applications?

Despite our leadership in the market, a large majority of the industry is still relying on conventional methods and is untapped. We want to change that and move them on to our technologies. The market leaders in different segments use our products but that is just the starting point for the rest of the industry to follow. At the same time, the Indian market is highly diverse and there is a huge potential to develop new applications with our new and existing technologies. Our solutions can increase reliability, reduce maintenance and servicing costs and improve productivity.

How is your customer service and distribution network in India?

We have a pan-India sales team and a base of distributors who can service the customer at his convenience. We also have a customer service team and a technical service team that can provide information on product and performance and resolve any issues on-site if needed. Additionally, we also have a toll-free number and an enquiry link where the customer can contact us for any information, product or service.

Do you have any joint ventures in India?

Henkel Teroson India Ltd, headquartered at Gurgaon, is a joint venture company of Henkel KGaA and Anand Automotive Systems and has technical license with Sunrise MSI Corporation, Japan. The company manufactures and supplies adhesives, sealants and NVH products to all automotive OEMs in India. Henkel Chembond Surface Technologies Ltd, established in 1996, is a joint venture between Henkel KGaA and Chembond Chemicals Ltd. Headquartered in Navi Mumbai, it operates in the business areas of metal treatment chemicals, which includes pre-treatment chemicals, neutral cleaners, lubricants, and coatings. The company offers its products to the Indian automotive OEMs and component suppliers, steel industry, general industry, appliance, construction equipment, aviation, defense, and aluminium customers.

Related Products

Workstation Metallic & Hardwired Consoles

Werner Electric introduces the Workstation Metallic & Hardwired Consoles, offering durability and integration for seamless operation in control rooms. Read more

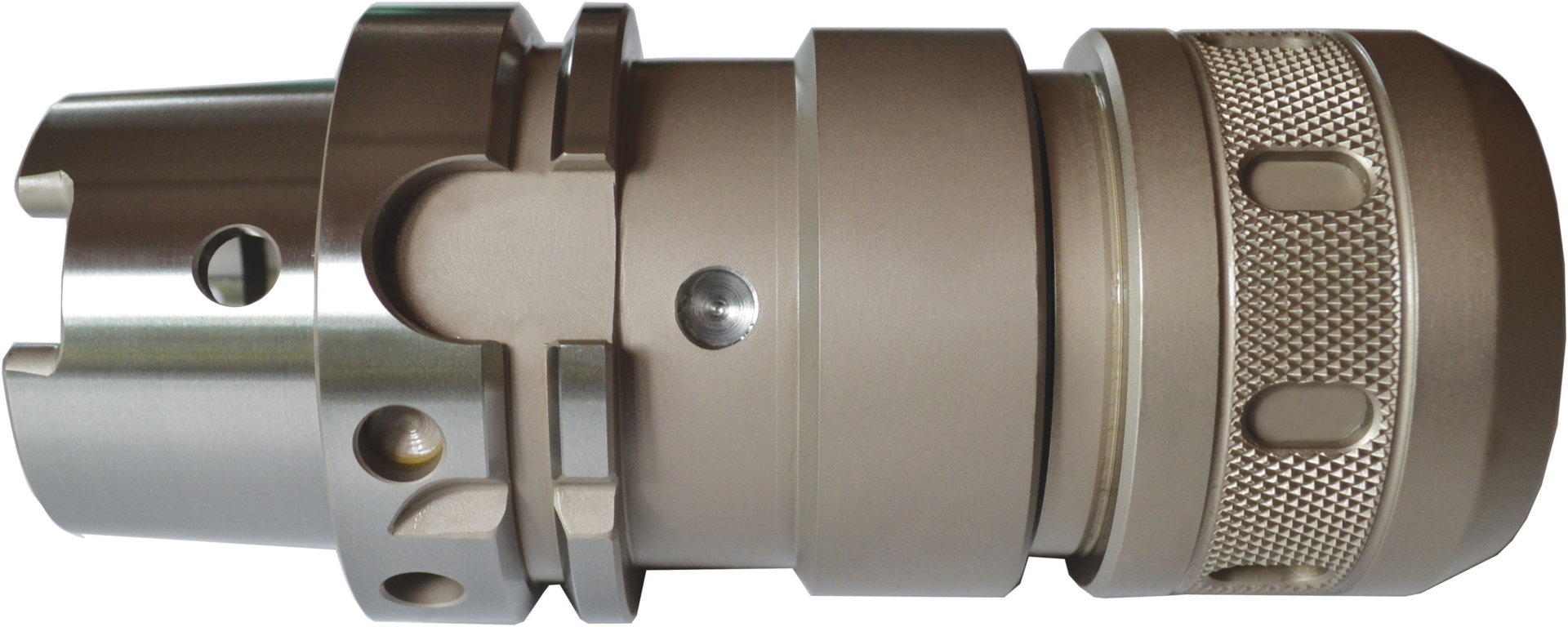

Hi-power Milling Chucks

Bilz Tool

offers a wide range of hi-power milling chucks.

Spur Gears

Shubham Gears is engaged in offering a comprehensive variety of spur gears.