Schedule a Call Back

Manufacturing sector is experiencing a significant paradigm shift

Interviews

Interviews- Jan 22,24

Related Stories

CEAT Partners CleanMax for 59 MW Hybrid Wind–Solar Power Project

CEAT has partnered with CleanMax to source ~59 MW of hybrid wind–solar power for its Halol and Kanchipuram plants, boosting clean energy use to around 60 per cent and cutting emissions significant..

Read more

Spray Engineering Devices drives Parag Agro’s 7000 TCD expansion

SED’s phased modernisation programme has enabled Parag Agro to scale sugar production to 7,000 TCD while achieving significant gains in energy efficiency and sustainability.

Read more

How is AI shaping the future of cement milling?

AI is transforming cement milling by enabling dynamic, data-driven control that improves energy efficiency, stabilises throughput and enhances asset reliability. By leveraging real-time data, predic..

Read moreRelated Products

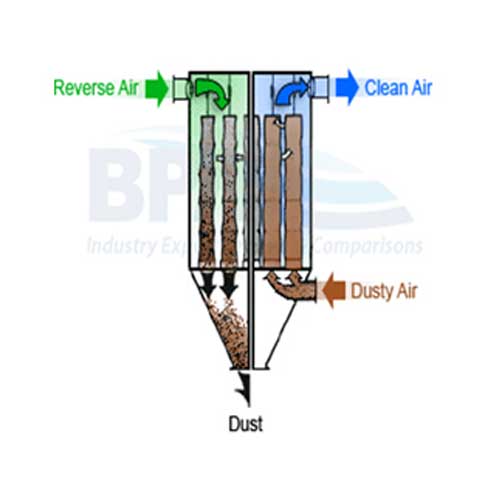

Reverse Air Bag House

ABR Enviro Systems offers a wide range of reverse air bag house.

High Quality Air Knife System

Superchillers offers high quality air knife system. Read more

Compact Cylinders -Vadvu Series

Vijay Air Control offers a wide range of compact cylinders -Vadvu Series