Schedule a Call Back

Indian electronics industry's mission $ 500 billion

Articles

Articles- Jan 30,25

In December 2024, India's electronics exports surged by 35.1 per cent to touch a two-year high of $3.58 billion from $2.65 billion in December 2023, according to the Minister Commerce and Industry, Government of India (GoI). Similarly, exports of electronics witnessed a jump of 27.4 per cent in April-November 2024 to $22.5 billion, from $17.66 billion during the same period in 2023. This data reflects the increase in foreign demand for high-value Indian electronics goods and rising domestic production capacities. Sanjeev Srivastava, Head of Automation Business, Delta Electronics India, explains, “The electronics manufacturing landscape in India has undergone a remarkable transformation in the last 5–6 years. With initiatives like Make in India and Digital India, the government has laid a strong foundation for boosting domestic manufacturing capabilities. The introduction of the Production-Linked Incentive (PLI) scheme has been a game-changer, incentivising local production and reducing dependency on imports. Investments in technology, infrastructure, and skill development have further enhanced India's global competitiveness. The growth of the manufacturing ecosystem and partnerships between global players and local manufacturers have fostered innovation, leading to an increasingly sophisticated manufacturing environment that supports high-quality production and exports.”

In 2020, Prime Minister Narendra Modi gave a kick-start to India’s vision of self-reliance (Atmanirbhar Bharat) through economic policies and incentives that included a focus on electronics and semiconductors. The end goal was to make India a product nation. Sanjeev Keskar, Chief Executive Officer, Arvind Consultancy, observes, “Progress in electronics manufacturing is very good. Five years back almost 2/3rd of electronics products were finish good imports and 1/3rd was domestically manufactured. In 2022-23, India’s total consumption of electronics was $ 120 billion and we had $ 80 billion domestic manufacturing and $ 40 billion in finish good imports. So, 2/3rd was manufactured in India. This is mainly due to PLI scheme. Mobile phones contribute to around 45-50 per cent of the total market and due to PLI scheme most of the mobiles are now getting manufactured in India.”

Figure 1:

Domestic electronics production ($ 101 billion)

|

Electronic segments |

Share |

|

Mobile phones |

43% |

|

Consumer electronics |

12% |

|

Industrial electronics |

12% |

|

Electronic components |

11% |

|

Auto electronics |

8% |

|

Others |

14% |

Source: Teamlease Degree

Apprenticeship

Figure 2: Rising exports & domestics

electronics production

|

Year |

Exports |

Production |

|

FY24 |

$ 29.12 bn |

$ 101 bn |

|

FY17 |

$ 5 bn |

$ 49 bn |

Source: Minister Commerce and

Industry

Figure 3: Soaring demand for electronic components

|

Year |

Value |

|

2023 |

$ 45.5 bn |

|

2030 |

$ 240 bn |

Source: CII

Electronics manufacturing has taken off in a big way in India over the last 10-15 years, now it needs to be ready for the next leap. “Most mobile phones for domestic use are currently being manufactured in India, and the export of phones made in India has also taken off. Most of it is at manufacturing level and part of it is at assembly level and it is being done as contract manufacturing for global brands like Apple, Samsung, Xiaomi, One Plus etc. The PLI incentives and selective application of tariffs has helped in growing this ecosystem tremendously. The next challenge for growing electronics manufacturing in India is to increase the value addition in manufacturing by making mechanicals, connectors, cables etc. and then move on to passive components, submodules and semiconductor chips for these products,” comments Dr Satya Gupta, President, VLSI Society of India.

Increasing value addition

Though final assembly of electronics has scaled at a rapid pace, under the existing PLI schemes, in India, local value addition has lagged behind. Components like printed circuit boards (PCBs), camera modules, display sub-assembly, lithium-ion cells, speakers, vibrator motors and mechanics make up around 50 per cent of the bill-of-materials in a mobile phone or a laptop. India’s demand for electronic components is projected to surge from $45.5 billion in 2023 to $240 billion by 2030, fuelled by the rising domestic production of mobile phones, as per a CII report.

The report has identified components and sub-assemblies of batteries, camera modules, mechanicals, displays, and PCBs as high priority for India. These components have either a nominal production in India or are heavily import-dependent. India can hardly afford to sustain this trend of importing the priority components, stated the CII report. Thus, building a robust domestic supply chain is crucial for India’s electronics manufacturing industry.

Nikhil Rao explains, “Dependence on imports not only increases costs but also introduces logistical complexities and vulnerabilities. To address this, we must focus on developing a local supplier ecosystem that can meet the industry’s demands. Government initiatives, such as the upcoming PLI schemes for components, are critical for building a strong local supply chain. These programs provide financial incentives to suppliers, encouraging them to invest in localisation and advanced manufacturing capabilities. The government has learned valuable lessons from the success of the mobile phone PLI scheme and is applying these insights to other segments. By engaging closely with industry stakeholders, the government ensures that its policies address real-world challenges and opportunities.”

The Finance Ministry is reportedly planning to roll out a ? 250 billion incentive scheme aimed at stimulating local manufacturing of electronics components. Through the scheme, the government is targeting to boost local value addition in electronics manufacturing to 35-40 per cent from 15-18 per cent at present and eventually covering 50 per cent of the entire non-semiconductor bill of materials.

Semiconductors: Ready for a take-off

Semiconductors are definitely a buzz word in Indian household today and the government has realised that semiconductors play a key role in modern electronics and driving technological advancements. “A few years ago, we were mostly looking at augmenting designs teams but today, we want to build self-reliance and build that ecosystem towards that goal. From a design standpoint, we are quite mature and there are Design Linked Incentive (DLI) schemes to help fast track indigenous designs,” says Malini Narayanamoorthi.

Local production of semiconductors is considered to be pivotal for the success of India's domestic electronics manufacturing goals. For this, the Union Government launched the India Semiconductor Mission (ISM) and incentive scheme for the display manufacturing ecosystem with an outlay of ? 760 billion in December 2021. “The Indian semiconductor industry has made remarkable strides in 2024, with the government’s transformative India Semiconductor Mission and cumulative incentives surpassing ?760 billion, attracting investments in state-of-the-art fabrication facilities and design ecosystems. The sector is projected to grow at a CAGR of over 19 per cent between 2023 and 2027, reflecting the nation’s commitment to becoming a global semiconductor powerhouse. This progress is propelling India into a key position in the global semiconductor value chain,” said Hitesh Garg, Vice President and India Managing Director, NXP Semiconductors (one of world’s largest semiconductor manufacturers), in a statement.

According to Dr Satya Gupta, in the last three years, phenomenal progress has been made in semiconductor manufacturing. “Today, India offers the best incentives in the world for semiconductor manufacturing which totals up to 70-75 per cent of the project cost between government of India and various states. This has helped in getting investments of more than ? 1.5 trillion from domestic and global companies, namely Micron Technology, Tata Electronics, CG Power and Kaynes Technologies with one ATMP plant, three OSAT plants and one wafer manufacturing plant. Most of these facilities have started building these facilities and the chip production should start as early as second half of 2025 by Micron, with others following up in next few years,” he says.

India Semiconductor Mission has approved five semiconductor units, with the foundation stone for India's first commercial semiconductor fab being laid in March 2024. “Yes, good progress in ISM for silicon fabs but we need a top global brand in compound semiconductors. This should have happened in phase 1,” opines Dr Ajai Chowdhry.

Dr Satya Gupta points out that semiconductors are at the heart of every electronics device today and most advanced gadgets and products for digital infrastructure worldwide would not be possible without the advances in semiconductors. “For example, Generative AI, which is the hottest area, would not be possible without fabulous advances in computing and storage both of which are primarily semiconductor products. The same is the case for mobile phone industry which is almost $40 billion market in India where the semiconductors are the main engine of every phone,” he observes.

Fab or fabless: Find the right balance

Electronic products depend on supply of semiconductor chips and semiconductor chips are primarily developed by the fabless companies like Qualcomm, Broadcom, Nvidia, AMD etc. “These fabless companies manufacture chips in a contract manufacturing model at various fabs across the world like TSMC, Global Foundry, UMC, PSMC etc. But, the product is owned by the fabless company and not the semiconductor manufacturing company,” explains Dr Satya Gupta.

Today, fabless chip product companies are larger than the semiconductor manufacturers. For example, Nvidia (the largest fabless company) has more than $3.5 trillion market cap compared to $1.2 trillion market cap of TSMC, the largest semiconductor manufacturing company. “When we talk about a robust ecosystem for supply of chips, it is important to develop both fabless chip product companies and semiconductor manufacturing companies. In last three years, after India Semiconductor Mission was launched, more than 95 per cent of the investments and incentives have gone rightfully for the manufacturing. As we move forward, in the next phase the incentives for semiconductors have to be more balanced, like 80 per cent for the manufacturing and 20 per cent for the fabless semiconductor product companies,” he suggests.

Global semiconductor landscape

The nature of the semiconductor market is extremely cyclical and this often results in extreme highs and lows. Global production of semiconductors over the last two years has been highly variable depending on the country. The key end user sectors for the industry are primarily electronics and automotive. According to the World Semiconductor Trade Statistics (WSTS) forecast, primary areas of growth are memory and logic integrated circuits. These categories cover chips used in everything from computers and smart phones to MRI machines and smart refrigerators.

Figure 4: Major semiconductor manufacturing countries

(2024)

|

Countries |

Share |

|

China |

43% |

|

South Korea |

13.50% |

|

Taiwan |

9% |

|

Singapore |

7% |

|

Japan |

6% |

|

Others Countries |

21.50% |

Source: Interact Analysis

Regions in Asia – China, South Korea, Taiwan, Singapore and Japan – dominate the global semiconductor manufacturing space with more than 78 per cent market share. In recent years, the smaller regions - namely Taiwan and Singapore - have been making big gains with a dedicated focus on the semiconductor market. “This focus on semiconductors has slowly enabled these territories to overtake Japan in the production of chips. Both Singapore and Taiwan have strong government support, well trained workforces, a focus on research and development and have received large amounts of investment in the sector from both domestic and international companies. Taiwan has TSMC, which is a global leader in advanced chips, while Singapore has carved out a niche for itself as a packaging and testing hub,” explains Tim Dawson, Vice President – Industrial Automation, Interact Analysis.

With the AI boom taking off, one can expect to see even more investments in the semiconductor industry, as technology evolves and the complexity and need for more chips continues. This is likely to drive more assembly and testing capacity at a global level. Another thing to consider is the geopolitics of semiconductor production. Dawson says, “One of the key reasons the US is focusing so much of its resources on the semiconductor sector is that it does not want key infrastructure and supply chains to be reliant on Chinese-produced semiconductors. The US is not alone in this and I suspect we will see the smaller regions make inroads into China’s market share as exports switch to these regions.”

With respect to India emerging as a major player in the global semiconductor manufacturing space, he says, “Anything is possible, but realistically probably not any time soon unless there are significant changes to the current market. India accounted for just 0.25 per cent of the Manufacturing Industry Output (MIO) value in 2024 for semiconductors and components. While it might grow rapidly internally, its competitors are simply too far ahead in terms of level and volume of production for India to make much headway. India does have strengths which could help it in the longer term, such as R&D centers for many the top semiconductor design companies and around 20 per cent of the world’s semiconductor design engineers. On the other hand, India imports about 90 per cent of its semiconductors and is reliant on other regions for growth in the sector.”

Hurdles on the road

The growth of the electronics industry in India also faces several challenges, despite its tremendous potential. Sanjeev Srivastava elaborates, “One of the primary issues is the dependency on imports for critical components such as semiconductors, which creates supply chain vulnerabilities. Infrastructure limitations, high logistics costs, and regulatory hurdles add to the complexity of scaling operations. The industry faces a shortage of skilled labour to meet the demands of advanced manufacturing processes. High raw material costs and intense global competition also pose significant challenges. However, consistent policy support, enhanced public-private collaboration, and a focus on innovation and technology can help overcome these barriers and unlock the industry’s full potential.”

There is a huge opportunity ahead of the country as building a complete electronics ecosystem with the government backing opens up a lot of windows ranging from materials, design, equipment, tooling manufacturing etc. “With opportunity comes the challenges as well. We do have to steadily build up every piece of the puzzle. Setting up manufacturing for semiconductors takes time, resources like uninterrupted electricity and trained manpower,” observes Malini Narayanamoorthi.

According to Sanjeev Keskar, there are three key challenges for India in electronics manufacturing:

1. In India, local value addition in electronics manufacturing is less than 20 per cent. For mobile phones, consumer electronics and IT hardware, India imports CKD (completely knocked down) kit and do only EMS activity which gives us 10 per cent value addition. This needs to be changed; otherwise our local value recognition will be small.

2. There is a lack of semiconductor and passive component manufacturing eco system. Components contribute almost 50 per cent of the value and today India imports most of them.

3. There is a need for product innovation and VLSI chip development. India has great design talent, but it works for either global companies or as design services companies. India has to focus on creating IP/technology/chips and products as it carries great value.

Keskar believes that DLI scheme for fabless semiconductor designs needs lot of improvement. Against goal of 100 companies in three years, the government has managed to approve only 17 proposals. “The industry should also focus on passive components/connectors and bare PCB manufacturing as they contribute to 15 per cent plus value of any product,” he adds.

Unavailability of skilled workforce could hinder the growth of Indian electronics industry. According to a report by TeamLease Degree Apprenticeship, the electronics sector, which is expanding at a compounded annual growth rate of 25-30 per cent, is poised to generate 12 million direct and indirect jobs in the coming years. The sector is expected to create direct employment for nearly 1 million engineers, 2 million ITI-certified professionals, and 0.2 million specialists in areas like AI, ML, and data science, while non-technical roles are projected to generate 9 million indirect jobs, showcasing its vast potential to drive economic growth. However, the industry could face a shortage of 10 million skilled professionals, which will be needed to maintain and accelerate growth in the electronics sector.

Table 1: Employment

projections in electronics sector by 2027

|

Types |

Jobs |

|

Engineers |

1 million |

|

ITI-certified professionals |

2 million |

|

Specialists in AI, ML and data science |

0.2 million |

|

Indirect jobs |

9 million |

Source:

Teamlease Degree Apprenticeship

India started late in semiconductor manufacturing primarily because the earlier efforts in last two decade did not take-off for many reasons. “The challenges like talent, raw materials, technology integration are part of every business and once the investment, incentives and technology partnerships are in place these are very solvable problems with right focus and efforts. For example, vendors of raw materials like chemical and gasses have already started coming to India when they sensed business opportunity with upcoming fabs and packaging units and obviously aided with right facilitation and support from the government. Technology integration is a technical problem and with right support from technology partner is very achievable task. Regarding the talent, some of the initial senior people have to be brought in from outside the country with right experience and the rest can be developed both at engineering level and technician level. The task is challenging, but very solvable problems,” says Dr Satya Gupta optimistically.

Manufacturing trends

Emerging technologies like artificial intelligence (AI), machine learning (ML), and 3D printing are transforming the electronics manufacturing industry by improving process quality, boosting efficiency, and optimising resource utilisation. “Industry 4.0, AI, ML, IoT, and robotics will change the future of electronics industry. India has excellent start ups working in this domain but support available to these start-ups is limited and their success rate is low. To tap new opportunity, we need to provide support (both financial and technical mentoring) to these start-ups to make them successful and capture the product innovation market from India,” says Sanjeev Keskar.

The future of the electronics manufacturing industry will be shaped by several transformative trends. Sanjeev Srivastava explains, “Smart manufacturing, driven by Industry 4.0 technologies such as AI, IoT, and robotics, is set to revolutionise production processes, making them more efficient and sustainable. The push for green technologies, including the adoption of renewable energy sources and low-carbon manufacturing practices, will become a defining factor in the industry’s evolution. The growing demand for 5G-enabled devices, coupled with advancements in semiconductor technology, will further drive innovation. The integration of digital tools for predictive maintenance, supply chain optimisation, and quality control will redefine operational efficiency and product reliability.”

According to Hitesh Garg, as we step into 2025, the focus will shift towards system design and AI-driven innovations, with semiconductors at the heart of India's transition into the intelligent age. “Initiatives like the India AI mission and advancements in edge computing, 5G, and IoT are creating unparalleled opportunities to integrate cutting-edge AI capabilities into system design. These innovations will accelerate industries such as automotive, healthcare, and telecommunications, enabling smarter, more efficient solutions. With a vibrant talent pool and robust digital infrastructure, India is well-positioned to leverage its semiconductor & ESDM (Electronics System Design and Manufacturing) ecosystem to shape a future defined by intelligence on the edge and connectivity,” he added.

Burgeoning demand

So far, the government has received commitments to investment ? 1.523 trillion ($18.15 billion) in the semiconductor space from investors. “The semiconductor industry in India is currently experiencing significant growth and transformation and the semiconductor market in India is projected to reach approximately $110 billion by 2030. Government initiatives are expected to create a robust semiconductor ecosystem in India, promoting local manufacturing and reducing dependency on imports,” says Malini Narayanamoorthi.

The semiconductor industry is set to be propelled by key macro trends such as AI, autonomous vehicles, sustainable electronics, edge computing, and electric vehicles. In addition to technological advancements, geopolitical factors and the growing demand for supply chain self-reliance are influencing the industry's growth across various countries.

With the tension between China and developed countries (led by the US and European Union) increasing, India needs to take advantage of the situation to develop a robust domestic manufacturing ecosystem for electronics and semiconductors. Dr Ajai Chowdhry opines, “India should focus on being a product nation in both systems and chips to replace an untrustworthy China in the near future. In this increasingly unipolar world, we need to create strategic autonomy by owning technologies. With our vast pool of fabless designers, we should create RISC-V based chips for all our requirements to prevent problems due to actions of the US and China in controlling the export of their technology as has been reported today.” RISC-V (pronounced as ‘risk-five’) is an open-source instruction set architecture (ISA) designed to create custom processors for a wide range of applications, including embedded systems and supercomputers.

Scaling new heights

India’s electronics exports are projected to gain further momentum with the establishment of semiconductor manufacturing facilities in the country. Nikhil Rao believes that India’s electronics manufacturing industry is on the cusp of unprecedented growth. “The success of mobile phone manufacturing has demonstrated the country’s potential, and this success is now being replicated across other sectors. Key growth areas include IT hardware, automotive electronics, and semiconductors. The government’s incentives, coupled with bilateral trade agreements, provide a favourable environment for both domestic and export-focused manufacturing. Additionally, advancements in semiconductor manufacturing will further strengthen India’s position as a global leader in electronics.”

The electronics industry aims to reach $500 billion in manufacturing output by 2030. To achieve this objective, the sector must expand five times within the next five years, closing a $400 billion production gap. Although the Indian electronics industry currently plays a limited role in global value chains, it has significant growth potential by expanding beyond final assembly to encompass design and component manufacturing. “India has a huge opportunity in investing in critical technologies of the future and create a leadership position with abundant talent available in India. I see a bright future for semiconductor technology, products and manufacturing in India and we are on the right path to make the country a strong electronics and semiconductor product nation,” concludes Dr Satya Gupta.

Related Stories

Indian manufacturing sector has a very promising outlook: Amitabh Kant

In this interview with Rakesh Rao, Amitabh Kant, India's G20 Sherpa and former CEO of NITI Aayog, explores the country’s transformative journey in the last few years and potential of the Indian ma..

Read more

Parson provides high-performance solutions for green applications: Biplav Nayak

The growing emphasis on environmental preservation, stricter chemical regulations, and economic competitiveness, Parson Adhesives innovates with solutions that promote pollution prevention, waste re..

Read more

Indian women in the semiconductor sector to rise from 25% in 2025 to 35% by 2030

India has the potential to bridge the gender gap and significantly increase women’s representation in the semiconductor sector, with women's participation expected to rise from 25% in 2025 to 35% ..

Read moreRelated Products

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.

“Kusam-Keco” Partial Discharge Acoustic Imager - Model - Km-pdai

‘Kusam-Meco’ has introduced a new “Partial Discharge Acoustic Imager Model KM-PDAI.

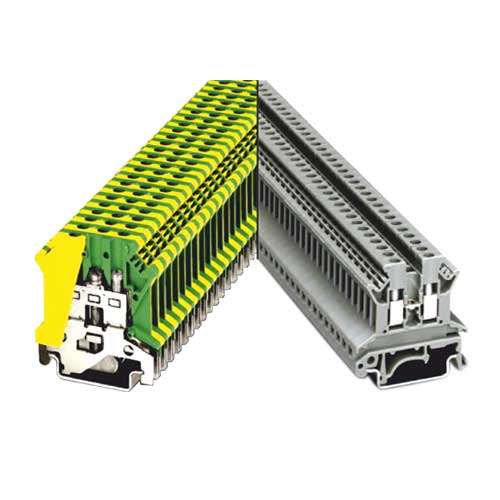

78 Series Din Rail Terminal Blocks

Werner Electric Private Limited offers a wide range of 78 series din rail terminal blocks.