Schedule a Call Back

India has become a very important market for Lapp

Interviews

Interviews- Feb 09,16

Marc Jarrault – MD – Lapp India Pvt Ltd, on the company’s two decades journey in India and its products and processes. Excerpts from an e-interview…

Lapp is in India for nearly 20 years. An eventful journey – how important is this market?

Lapp India began its operations in India in 1996 with a manufacturing unit in Jigani, Bangalore. Having made an investment of 2.1 million euro, the Bangalore unit is the second largest manufacturing unit of the Lapp Group. Looking at the potential of the Indian market, Lapp India started its second plant at Bhopal. This unit strengthens the company’s base in the single core wires segment as well as cater efficiently to growing customer demands in India.

As per the United Nations report, India’s urban population is expected to soar to about 540 million by the year 2030. Urbanisation has been spreading across India and industrialisation has played an important role in the urban growth. This has led to increase in demand for better infrastructure such as high-rise buildings to industrial parks, metros, etc. This is driving the demand for cables and conductors. Thus India has become a very important market for Lapp India.

From an SME to a global brand. What is the USP of Lapp’s manufacturing?

Lapp places high emphasis on quality. Lapp India adheres to certain tools and techniques to improve operational effectiveness and productivity. Some of the tools that Lapp India follows are:

Value Stream Mapping (VSM): This is a collaborative tool that allows the plant management and workforce to see the waste and non-value added activity from customers’ perspective.

Safety Tools and Near Miss Reporting: For Lapp India, safety is the 1st goal and every day, strive for zero accident culture. Lapp India also has a strong Near Miss/Unsafe Condition reporting program, where every member of the work force can report unsafe conditions/near misses to the plant management and immediate action is taken to close it.

Shop Floor Management: In Lapp India’s factory Visual Boards are present, where targets are set, daily plans are monitored, actions taken immediately if targets are not met and people working together to solve problems in the shop floor for the benefit of the customer.

Shop floor Kanban for Copper WIP: Lapp India has eliminated separate SAP scheduling to the Copper Section and have introduced Supermarkets/Kanbans for Drawn and Bunched Copper sections, where these supermarkets with controlled inventory, calculated from historical demand and future forecasts are maintained using tracks and visual boards.

Six Sigma Initiative: This has been launched at the Green Belt level for production engineers and managers to optimise copper, PVC and other inputs through use of Six Sigma tools like process mapping, FMEA, Fishbone diagrams, Pareto charts, Statistical Process Control (SPC) and Design of Experiments (DoE).

Total Productive Maintenance (TPM): Lapp India just launched this with key measurements such as MTTR, MTBF and OEE (Operational Equipment Effectiveness), that helps us identify bottleneck operations and down time management. This analysis helps us launch appropriate kaizen events for continuous improvement of lead times and availability of machines.

Other USPs include:

Comprehensive range of cabling solutions – from Power & Control, Data communication systems, Optical transmission systems, Accessories. More than 40000 products catering to more than 30 industry verticals Strength in manufacturing – Processes and systems – Value System Management allow us to reduce lead-time for our customers and maintain our manufacturing and quality excellence standards while achieving better productivity. This tools is used in both Bangalore as well as Bhopal Plants of Lapp India.

Lapp India has eliminated separate SAP scheduling to the Copper Section and have introduced Supermarkets/Kanbans for Drawn and Bunched Copper sections. Unless the Kanban (signal-in this case a magnetic card) is removed from the Bobbin when it is withdrawn by insulation line, bunched copper is not produced and operators can monitor if the supermarkets are empty using their eye and not through the complex SAP system, and Quality products – State-of-the-art testing facility/approval from international agencies/relevant certifications for industry verticals.

We are deploying lean systems in our warehouses for safety, quality (to eliminate missing and wrong articles), efficiency of packing and we have improved our month-end stock accuracy to > 99%.

The company has two plants in India. What is the total range manufactured?

The Bangalore plant has a capacity to manufacture about 60,000 km of Multi Core cables and 78,000 km of Single Core wires per annum.

The Bhopal manufacturing unit is helping us strengthen our base in the single core wires segment as well as cater efficiently to growing customer demands in India. It has an existing capacity of 1,000 km of single core cables daily, catering mainly to the Building Segment. The Bhopal facility also produces 36,000 km of Multi Core cables resulting in overall capacity increase of 60% in Multi Core cables, which is used in major industries today, in addition to the existing 216,000 km capacity in Single Core wires.

What are the special cables for solar power segments? Also for EVs and electromobility?

Some of the products and accessories that Lapp India manufactures:

Solar PV cables: Olflex Solar XLR-R®/Olflex Solar XLR WP®, with features like halogen-free and flame-retardant, good notch and abrasion resistance and weather/UV-resistant and ozone-resistant.

Modbus: Unitronic Li2YCY (TP)®, flame-retardant according IEC 60332-1-2, overall braid minimises electrical interference and decoupling of circuits by means of twisted-pair (TP) design (crosstalk effects).

LAN cable: Unitronic Lan Outdoor®, with features like transfer of digital and analogue data signals, suitable for outdoor use and direct burial, UV-resistant longitudinally and laterally watertight and LAN cables for structured building cabling.

FO cable: Hitronic HQW Armoured Outdoor Cable®, with features including central loose tube with up to 24 fibres, colour-coded fibres, longitudinal watertight, excellent rodent protection and robust, halogen-free outer sheath.

AC cables: Olflex Power LV Cables®, available in both armoured and un-armoured variants, in single, twin, three, four and multi core cross-linked polyethylene (XLPE) or polyvinylchloride (PVC) insulated with PVC tapped/ extruded inner sheath with PVC outer sheath, and

More than 10,000 different constructions, which serve the purpose of power and control application as per end users need. Besides, there are accessories cable outlets, cable ties, protective conduits, cable lugs and solar connectors.

What is the TIM system the company is planning to implement in its Indian operations?

At Lapp India we follow what is called as TIM (Technology And Innovation Management) system. It provides us a useful tool to understand how technology works in the innovation process and enables them to make sound business decisions. TIM makes us understand our ability to manage the generation of technical knowledge towards its successful commercialisation by us.

Advantages of TIM:

1. To provide new and improved products to the market

2. To create the right environment for innovation and how to innovate successfully

3. To reduce costs and enhance quality thereby improving customer value

4. To increase our speed to market with new product and application offering, and

5. It helps un in process standardisation.

Through this process we communicate our vision of business growth through new product development. To grow we should provide new and improved products to the market.

We should understand when to innovate and how to do it successfully and TIM provides us with the right framework.

How do you see the future for the company in India?

For the Lapp Group, India has always been a key focus, owing to the promising growth and opportunities that the country has to offer. Having in-depth knowledge and the understanding of the Indian industry has provided a thrust for us in the Indian market. We are also excited about the Make in India campaign launched by Prime Minister Narendra Modi. This campaign has laid out the red carpet to foreign investors to manufacture their products in India. While the wire and cable and industry does not get a direct mention in the campaign our focus is on supplying cables for applications pertaining to industries that is part of the campaign – such as power, oil and gas, electrical, cement, steel and construction, among others and gain benefit.

Related Stories

Madan Sabnavis: The major problem for SMEs is their low credit worthiness

In this interview with Pratap Padode, Editor-in-Chief, Smart Manufacturing & Enterprises (SME), Madan Sabnavis, Chief Economist, Bank of Baroda, discusses the status of the private investment cycle,..

Read more

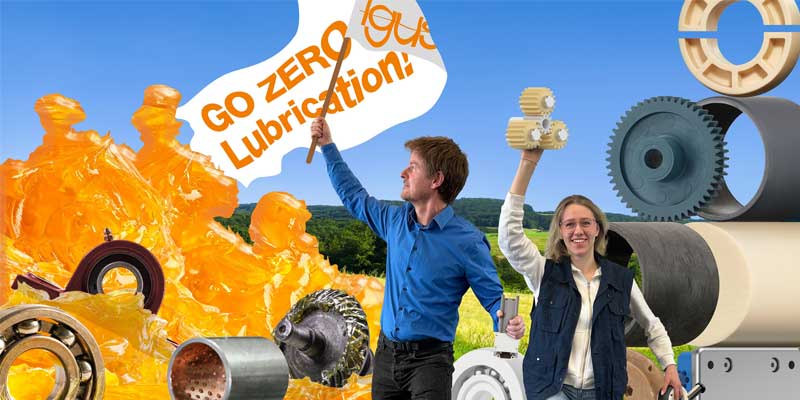

Go Zero Lubrication: Igus’ clean revolution with lubrication-free plastics

With $990 billion spent on lubrication per year worldwide, igus, at Hannover Messe 2024, demonstrated who can do without lubricants immediately and the role AI plays.

Read more

Gandhi Automations launches self-repairing clean room high speed doors

Manufacturing facilities across various sectors now rely on cleanroom environments to minimise dust and contamination during production.

Read moreRelated Products

Venturi Scrubber

AQC Systems Pvt Ltd is a manufacturer and supplier of a wide range of venturi scrubbers.

Automatic Self Adjusting Pipe Wrench

Solsons Exim develops automatic self-adjusting pipe wrench, 9”.

Sledge Brass Hammer

Manomay & Co offers a wide range of sledge brass hammer.