Schedule a Call Back

“Boiler industry is adopting advanced combustion technologyâ€Â

Interviews

Interviews- May 01,19

Related Stories

At Thermax, we are building next-gen captive plants: Kirtiraj Jilkar

The concept of captive power is constantly being redefined. The future lies in hybrid captive plants facilities that blend sources like solar, biomass, waste-to-energy, and traditional fuels with ad..

Read more

Thermax partners with Ceres for large-scale green hydrogen production in India

The partnership aims to accelerate the adoption of SOEC technology in India and globally, enhancing green hydrogen production.

Read more

Thermax scouts for a new green hydrogen partner

This is because a planned venture with Australian green energy firm Fortescue Future Industries (FFI) to develop green hydrogen projects in India did not materialise.

Read moreRelated Products

Biomass and Coal Fired Spreader Stoker Boiler

Sitson India Ltd offers a wide range of biomass and coal

fired spreader stoker boiler

Coil Type Boilers - VRS Series

Maxima Boilers Private Limited offers a wide range of coil type boilers - VRS Series

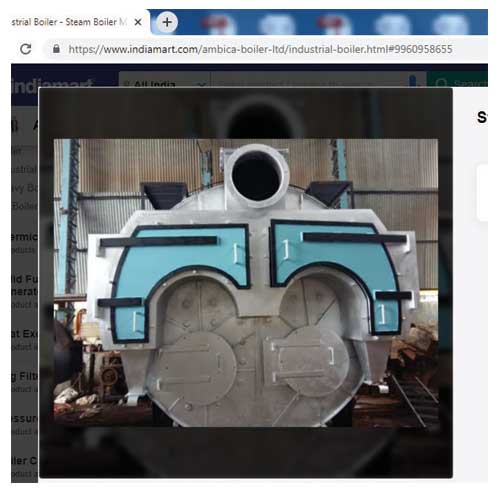

Steam Boiler

Ambica Boiler offers a wide range of steam boiler.