Schedule a Call Back

Welding is at the core of manufacturing and construction

Interviews

Interviews- Jun 01,18

.jpg)

Related Stories

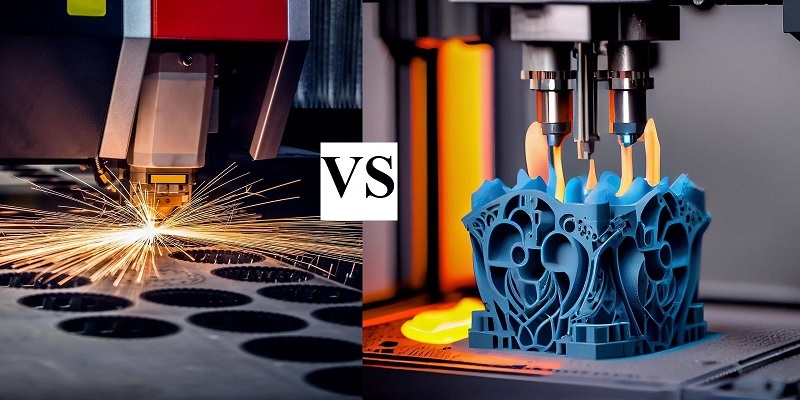

Intersection of 3D printing and laser cutting: A new paradigm in manufacturing

The intersection of 3D printing and laser cutting remains a niche area. However, it should gain prominence when people learn about use cases that demonstrate versatility and viability, says Emily Ne..

Read moreJindal Aluminium produces 115,920 MT of aluminium extruded products in FY23-24

Operating three cutting-edge manufacturing plants located in Bengaluru, Dabaspet (Karnataka), and a newly acquired facility in Bhiwadi (Rajasthan), Jindal Aluminium boasts a total manufacturing capa..

Read more

Zoho plans $700 million foray into chip manufacturing; compound semiconductors

Semiconductors occupy a pivotal position in India's economic agenda, with the government implementing a $10 billion package to fortify the industry's capabilities, positioning the nation to rival es..

Read moreRelated Products

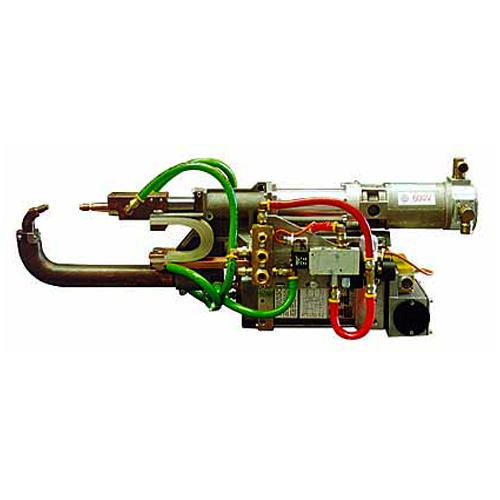

Spot Servo Pneumatic Welding Guns

Shreeji Weld

Industries manufactures a range of spot servo pneumatic welding guns.

Spot Welding Machine With Long Throat Arms

Arm Welders offers

long throat depth spot welding machine for fuel tanks.

Read more

Dc Tig Mosfet Base Welding Machine

Welding Aids

offers DC TIG (inverter base) mosfet base welding machine.