Schedule a Call Back

“Humans and robots need to work together for productive futureâ€Â

Interviews

Interviews- Dec 09,19

Related Stories

Global industrial robot shipments down in 2024, recovery likely in 2025

As investment cycles pick up and demand stabilises across key industries, 2025 could mark the beginning of a new growth phase, albeit one characterised by tighter margins and more nuanced competitio..

Read more

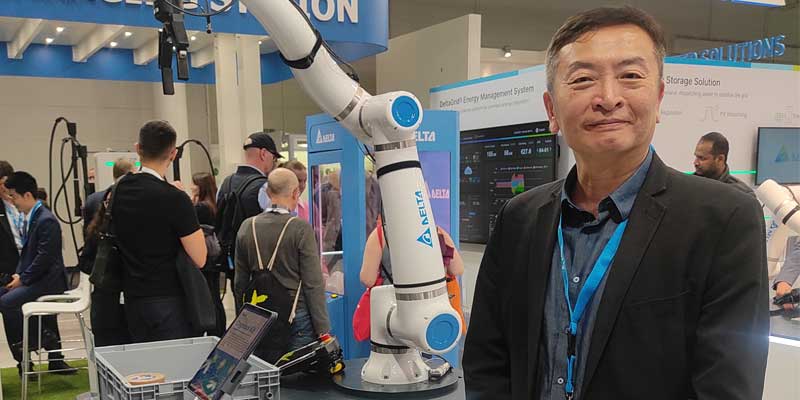

Localisation is Delta Electronics’ key strategy in India: Andy Sun

In this interview with Rakesh Rao, Andy Sun, Senior Director of Sales and Marketing, Industrial Automation BG, Delta Electronics, discusses manufacturing trends and Delta’s future growth plans for..

Read more

ICONICS rebrands as Mitsubishi Electric Iconics Digital Solutions

Mitsubishi Electric has supported ICONICS’ growth for over a decade, culminating in its full acquisition in 2019.

Read moreRelated Products

Collaborative Scara Robot

Malles Automated & Robotic Systems Private Limited

Robotic Deflashing of Aluminium Casting

Grind Master Robotic Deflashing Machine is an advanced and most reliable machine for Aluminium components. Robotic deflashing is a revolutionary technology developed by Grind Master Machines Pvt Lt Read more

Karmi Bot

Asimov Robotics offers a wide range of Karmi Bot.