Schedule a Call Back

Digitalization can make power generation more sustainable

Interviews

Interviews- Aug 01,18

Related Stories

Hannover Messe 2026 to focus on automation & digitalization, adds Defense Area

At the upcoming Hannover Messe, AI will be a recurring theme throughout all the halls, and will play a central role on almost all stands.

Read more

India’s demand for high-precision machine tools is rising: K Balasubramaniam

In this interaction with Rakesh Rao, K Balasubramaniam, Founder, Tsugami Precision India, discusses the evolving machine tools landscape and the company’s role in shaping India’s manufacturing t..

Read more

Let’s decarbonise: A turning point for mining in Asia

Sustainability uncertainties in mining are well known. Encouragingly, mining is already undergoing a notable transformation—one that brings with it great potential to build a more resilient and su..

Read moreRelated Products

Power Conversion Systems

POM Systems & Services Pvt Ltd offers a wide range of

PCS power conversion systems energy storage.

Hot Water Generators

Transparent Energy Systems Private Limited offers a wide range of Hot water generators - Aquawarm Superplus.

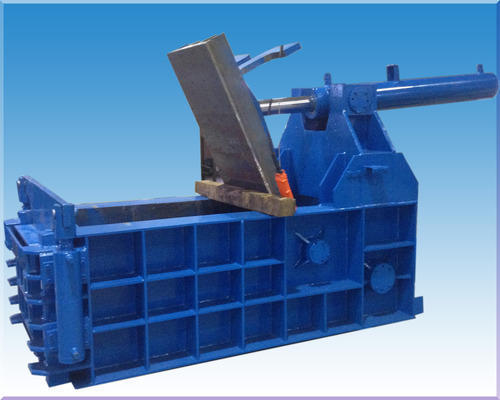

Scrap Baling Press

Fluid Power Machines offers hydraulic scrap baling press. Read more