Schedule a Call Back

Cutting processes need to be more intelligent in future

Interviews

Interviews- Jan 01,19

Related Stories

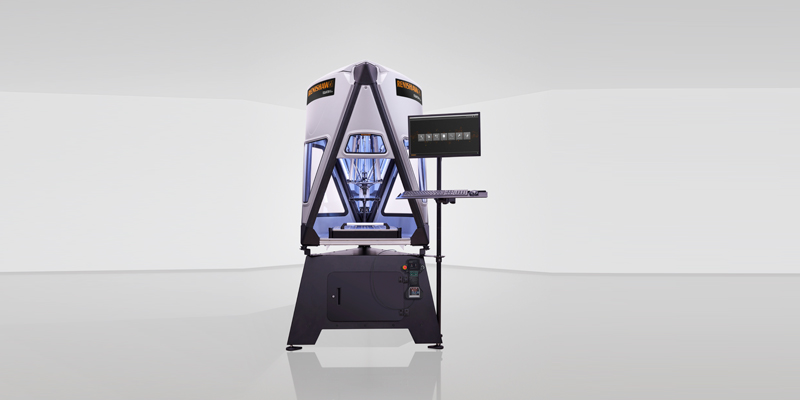

Renishaw Unveils Equator–X 500 Dual-Method Gauging System

Equator–X 500 dual-method system extends the Equator range of versatile gauges for shop floor process control, high-speed measurement and quality assurance

Read more

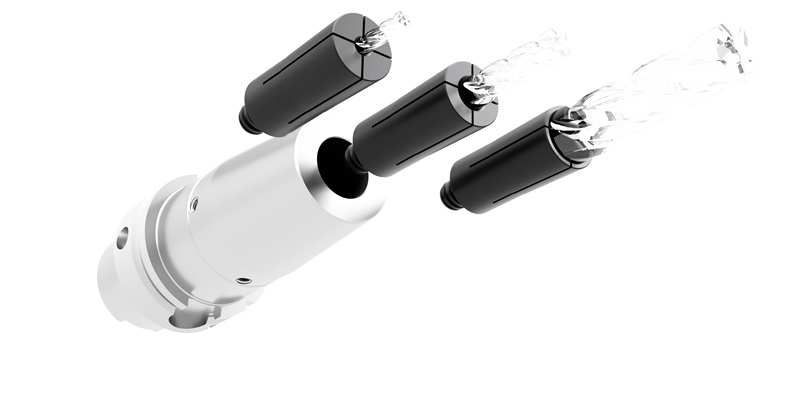

BILZ launches ThermoGrip® TMG Shrink Chuck

The new TMG is characterised by exceptional flexibility, high rigidity and optimised vibration damping.

Read more

WALTER unveils Automated Tool Production system for cylindrical precision tools

WALTER customers can easily retrofit the Automated Tool Production (ATP) system in their existing production facilities without having to change the existing system layout.

Read moreRelated Products

Precision Cutting Tools1

S S Trading Corporation offers a wide range of precision

cutting tools.

Slotting Head Unit for All Cnc Turn Mill Centers

Sphoorti Machine Tools Pvt Ltd offers a wide range of

slotting head unit for all CNC turn mill centers.

Slotted Tool Disc and Tool Holders

Prominent Machine Tools offers a wide range of slotted tool disc and tool holders.