Schedule a Call Back

50% of facilities in Krishnagiri is dedicated for power supplies, automation products”

Interviews

Interviews- Oct 31,23

Delta Electronics India Industrial Automation Business reached the milestone and crossed Rs 500 crore revenue in 2022. What factors contributed to this growth?

As the Head of Automation at Delta Electronics India, I am proud to share insights into how our Industrial Automation Business achieved the significant milestone of crossing 500 crores in revenue for the year 2022. Our success is attributed to several strategic pillars. First and foremost, our diverse portfolio of industrial automation products and solutions, known for their high performance and reliability, allowed us to cater to a wide array of industries and client needs. The integration of the Internet of Things (IoT) into our solutions has been transformative, facilitating the creation of efficient and responsive system architectures. Industrial Internet of Things (IIoT) solutions played a pivotal role in connecting industrial assets, enhancing efficiency, and providing real-time transparency.

Furthermore, our commitment to continuous improvement and innovation was evident in our successful entry into new sectors, including banking, infrastructure, paint, and steel industries. Notably, the acquisition of major accounts in the manufacturing industry during the third quarter of 2022 significantly bolstered our revenues.

Additionally, our organic growth strategy allowed us to gain new clients in emerging industries throughout the year. This consistent growth, driven by both volume and value, was a testament to our ability to adapt, innovate, and provide tailored solutions that meet the evolving needs of our clients. Looking forward, we remain dedicated to technological excellence and customer satisfaction as we continue our journey toward sustainable growth and leadership in the field of industrial automation.

How will Delta's new investment of around $500 million in Krishnagiri benefit the company as well as its customers?

I'm thrilled to offer additional insights into our substantial investment of approximately $500 million in Krishnagiri to establish a new manufacturing facility. Currently, we operate six factories in Krishnagiri, with three already in operation and the remaining three nearing completion in terms of construction. This strategic expansion seamlessly aligns with our strong commitment to the 'Make in India' initiative, aimed at promoting domestic manufacturing and fostering self-reliance. Once these facilities become fully operational, they will make a significant contribution to Delta Electronics' global presence.

Approximately 50 per cent of the manufacturing capacity in Krishnagiri is dedicated to producing power supplies and industrial automation products, with a primary focus on exporting these high-quality, technology-driven solutions globally. This underscores our pivotal role in the global supply chain, providing advanced and sustainable technologies to meet the evolving demands of international markets.

Over the next 3-5 years, we anticipate achieving a remarkable capacity utilisation rate of 60-70 per cent across these state-of-the-art plants. This reflects our unwavering commitment not only to boost economic growth in the Krishnagiri region but also to make a significant contribution to India's industrial landscape. We are enthusiastic about being part of India's journey toward technological advancement, self-reliance, and global competitiveness while reinforcing our position as a trusted leader in the field of industrial automation and sustainable solutions.

With the advent of automation, AI, ML, IoT, data analytics, cloud, etc, how has the dynamics in manufacturing changed with respect to usage of technologies – i.e. hardware as well as software - in recent years?

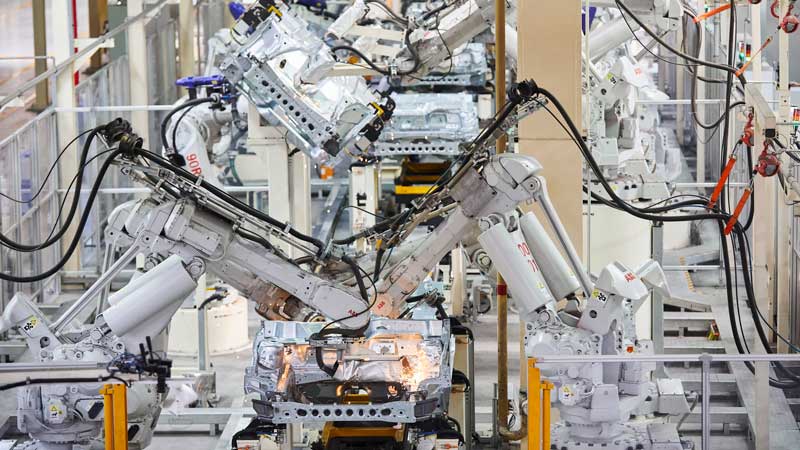

The manufacturing industry has undergone a profound transformation due to the advent of automation, AI, ML, IoT, data analytics, and cloud computing. These technological innovations have revolutionised traditional manufacturing processes, resulting in increased efficiency, cost reduction, and improved productivity. In terms of hardware, the integration of robots, sensors, and connected devices has become commonplace in manufacturing. Robots are now capable of executing repetitive tasks with unparalleled precision, while sensors collect real-time data on the production process, facilitating quality enhancement and process optimisation. On the software front, AI and ML are automating tasks such as predictive maintenance, quality control, and supply chain management. Additionally, AI-driven virtual simulations of manufacturing processes are enabling manufacturers to fine-tune their operations for optimal outcomes.

These technologies have reshaped manufacturing dynamics, enabling quicker and more efficient production with fewer defects. Furthermore, they facilitate product customisation to meet specific customer requirements, enhancing competitiveness. Manufacturers are increasingly utilising robotics for welding, painting, and assembly, resulting in improved efficiency and precision. Sensors are instrumental in monitoring equipment health, defect detection, and process optimisation. The IoT connects machines and devices, enabling real-time data collection and analysis for informed decision-making. Data analytics identifies trends and patterns, enhancing quality and efficiency. Cloud computing provides access to vast computing resources and data storage, further empowering decision-making and operational optimisation. As these technologies continue to evolve, the manufacturing industry is poised for further transformation, promising even more innovations and improvements in the years ahead.

How important will be digital manufacturing for India to become a $1 trillion manufacturing economy?

Digital manufacturing will play a pivotal role in India's ambitious goal of becoming a $1 trillion manufacturing economy. As demonstrated by the recent surge in manufacturing exports, which witnessed a remarkable CAGR of 15 per cent and reached $418 billion in FY22, India is poised for significant growth. This growth can be attributed to several key factors. Firstly, supply chain diversification has accelerated in recent years, making India an attractive destination for manufacturing. The COVID-19 pandemic exposed vulnerabilities in global supply chains, leading to a shift towards more resilient and diversified sourcing options.

Secondly, India has distinct advantages in certain manufacturing sectors, such as chemicals, pharmaceuticals, electronics, automotive, industrial machinery, and textiles. Leveraging these strengths will be crucial in achieving the $1 trillion target. Government initiatives to bolster manufacturing, capital expenditure infusion, increased merger and acquisition activity, and investment from private equity and venture capital firms have further stimulated growth. These factors create a conducive environment for digital manufacturing to thrive. To seize this opportunity, Indian companies must develop a clear export strategy, enhance execution capabilities, forge strategic partnerships to enable exports, and prioritise efficient capital expenditure for capacity expansion. Digital manufacturing technologies, including automation, data analytics, and IoT, will be instrumental in optimising operations, reducing costs, and ensuring competitiveness on a global scale. Embracing these digital advancements will not only help India achieve its manufacturing aspirations but also position it as a global manufacturing powerhouse.

What steps is Delta taking to develop Industry 4.0 ecosystem in India?

Delta Electronics is actively contributing to the development of the Industry 4.0 ecosystem in India through a multi-faceted approach. Firstly, we are investing significantly in research and development, focusing on cutting-edge technologies such as automation, robotics, artificial intelligence, and data analytics. These innovations serve as the foundation for Industry 4.0 solutions. Delta also collaborates with local partners, including universities, to harness local expertise and promote innovation. Moreover, the implementation of smart manufacturing practices in Delta's facilities, complete with IoT devices and sensors, enables real-time data collection for process optimisation and predictive maintenance. Additionally, Delta is committed to skill development, offering training programs to equip the Indian workforce with the necessary competencies for Industry 4.0. Furthermore, we promote green technologies and sustainability, aligning our practices with Industry 4.0's focus on efficiency and environmental responsibility.

High upfront cost is a big put-off for companies who intend to adopt automated/digital solutions. Are there low-cost entry routes into digitalisation/automation? How is Delta supporting the automation needs of SMEs?

Recognising the challenges posed by high upfront costs for automation adoption, especially among Small and Medium Enterprises (SMEs), Delta Electronics is actively facilitating accessible entry routes into digitalisation and automation. The company offers scalable solutions tailored to the specific needs and budgets of SMEs. Delta's portfolio includes a range of automation products, from basic to advanced, allowing businesses to start small and expand gradually as they see the benefits. Moreover, Delta provides comprehensive support services, including training and technical assistance, to help SMEs make a seamless transition into automation. Delta's commitment to innovation also leads to the development of cost-effective, energy-efficient solutions, further reducing the financial burden for SMEs. By offering accessible and scalable automation options, along with dedicated support, Delta Electronics aims to empower SMEs to harness the benefits of digitalisation and automation, enhancing their competitiveness and sustainability.

What are the emerging trends in automation and digital manufacturing?

In the realm of automation and digital manufacturing, several prominent emerging trends are poised to reshape the industry. Robotics and automation, which have been transforming manufacturing for years, are expected to continue their ascent. Robotic process automation is a pivotal driver of smart manufacturing, as robots are increasingly assuming tasks that are repetitive or hazardous, such as assembly, welding, and material handling. The advantages are manifold: robots can execute repetitive tasks with greater speed, accuracy, and precision than human workers, leading to improved product quality and reduced defects. By integrating robotics with Industrial Internet of Things (IIoT) sensors and leveraging big data analytics, manufacturers can cultivate a more agile and responsive production environment. This fusion of technologies promises enhanced system efficiency, reduced errors, decreased equipment downtime, and heightened worker safety across manufacturing operations. Moreover, the ability of robots to operate continuously translates into 24/7 production capabilities, significantly amplifying overall productivity.

What are your growth plans for Delta's Industrial Automation Business in India?

Delta's growth plans for our Industrial Automation Business in India are multifaceted and driven by a strong commitment to the Indian market. Our foremost goal is to expand our presence and reach in India by establishing a wider network of regional offices and strengthening partnerships with local businesses. Additionally, we aim to diversify our product offerings, delivering innovative solutions tailored to the specific needs of Indian industries, whether it's manufacturing, energy, or infrastructure. To better serve our customers, we are actively localising our product and technologies, through these strategic initiatives, we are dedicated to not only meeting but exceeding the demands of India's rapidly evolving industrial automation landscape, fostering sustainable growth, and delivering cutting-edge technology to our valued customers.

Related Stories

Quest to increase efficiency in manufacturing driving robots demand in India

With 59 per cent increase in robot installation in 2023, India has emerged as one of the strongest growing markets. Many believes robots will be central to achieving India’s ambition of becoming a..

Read more

Delta Electronics will soon introduce cobots in India: Manish Walia

In this interview with Rakesh Rao, Manish Walia, Head - Industrial Automation, Delta Electronics India, explains the importance of advanced automation and robotics to enhance the operational efficie..

Read more

Role of cybersecurity in smart manufacturing

As smart factories become the backbone of modern manufacturing, ensuring robust cybersecurity has never been more essential. These connected, automated facilities are prime targets for cyberattacks ..

Read moreRelated Products

Fanless Industrial Pc for Smart Manufacturing

CONTEC Launches BX-M4600 Series - Fanless Industrial PC for Smart Manufacturing.