Schedule a Call Back

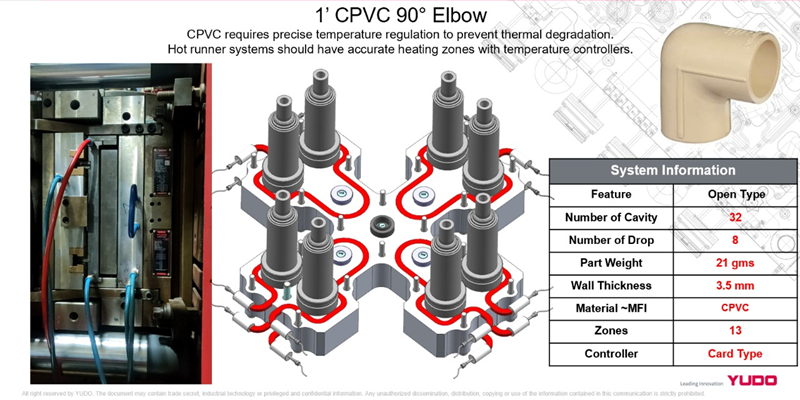

Yudo India rolls out Hot Runner Systems for CPVC to enhance local manufacturing

Industry News

Industry News- Apr 16,25

Yudo India has

introduced a new Hot Runner technology aimed at transforming the CPVC

(Chlorinated Polyvinyl Chloride) material which is mainly used for pipe &

its accessories segment in India, significantly reducing material wastage and

enhancing production efficiency.

“CPVC is a challenging material. For years, the industry had no option but to

accept the high wastage levels. With our new Hot Runner technology, we are

enabling local manufacturers to produce at scale with consistency,” said Vishal Agarwal, President, Yudo India.

The new solution, developed by Yudo, enables CPVC Molders to reduce raw

material wastage by 40 to 80%, while increasing production efficiency

by 20 to 40%, claims Agarwal. This comes at a time when the Indian

market is witnessing growing demand for high-performance pipe systems, with

nearly 50% of the country’s CPVC material currently being imported.

Traditionally, the Indian CPVC Injection Molding relied on outdated processes

that led to considerable material loss. With the introduction of Yudo’s

technology, the industry is expected to achieve better utilisation of resources

and reduce dependence on the material imports.

India is among the largest consumers of CPVC pipe fittings globally. The domestic

demand has expanded with increasing urbanisation and infrastructure

development. However, high raw material costs and process inefficiencies have

long hindered local manufacturers.

Yudo’s new systems are set to impact the import-driven segment of the CPVC

market, aligning with the government’s push for local manufacturing under the

'Make in India' initiative. The successful application of Yudo’s system could

lead to broader technology upgrades in related sectors, particularly where

precision and moulding consistency are critical with very high volume of

production, added Agarwal.

Related Stories

Calcom Vision Reports Record Q3 and 9M FY26 Revenue, Strong YoY Growth

Calcom Vision Limited posts highest-ever 9MFY26 revenue at Rs 150.3 crore, with robust growth across lighting and EMS segments.

Read more

IEMI 2026 Concludes with Strong Industry and Defence Outcomes

IEMI 2026 concluded in Bengaluru with over 1,800 delegates, key MoU signings, industry reports, and global participation reinforcing India’s electronics manufacturing ambitions.

Read more

Birla Precision Technologies Unveils New Brand Identity and Vision

Birla Precision Technologies Limited announces a new brand identity, marking its evolution into a technology-driven, diversified and future-ready precision engineering company.

Read moreRelated Products

Rubber Sheets Material

Talbros Sealing Material Pvt Ltd offers a wide range of rubber sheets materi Read more

Rail Rubber Pad

Chamunda Enterprise offers a wide range of rail rubber pad.

Insulation Polyester Film

TMA International Private Limited offers a wide range of insulation polyester film.