Schedule a Call Back

Yokogawa releases platform for Advanced Control and Estimation R5.03

Industry News

Industry News- Jun 29,21

- Multivariable model predictive control (the control of multiple variables based on predictions made using models of the dynamic characteristics of plant responses)

- Soft sensing for estimating quality in real-time based on temperature, flow rate, pressure, and other process values

- Customization of calculations

- A) Support for OPC UA: Version 5.03 conforms to OPC UA, the latest version of the OPC communication standard. OPC is the prevailing data exchange standard in the industrial automation field. Support of the latest OPC version enables users to securely exchange data with OPC UA devices and work with data from a wider range of sources.

- B) Addition of new Base Layer Control (BLC) model: A new BLC model that employs proportional integral differential (PID) control logic has been added. This model uses the PID parameters of a distributed control system (DCS) to represent the dynamics of a PID loop. This improves control by reducing mismatches with the process described by the BLC model.

- C) Expansion of Shed Logic to Event Logic: Shed Logic is a function that customizes how applications operate. It gives users the freedom to customize the behaviour of their applications to suit the operating conditions of a plant. Shed Logic is now called Event Logic, with expanded functionalities that eliminate the need for custom code and enable event-based processing for measurement validation, model change, etc.

- A) Design-time advisor: This function verifies the parameter values for applications, processors, and variables that have been set using Design-Time and displays a warning message for any invalid parameter settings. By making it easier to identify and correct configuration errors, this helps to improve applications.

- B) Automatic trend scaling: The scale of the trend pen (upper and lower limits of the trend display) can now be adjusted automatically. This feature reduces the time and effort required for setting the trend scale.

- C) Visualization of OPC performance data: It is now possible to view OPC performance metrics such as read time when accessing data from an OPC data access/unified architecture (DA/UA) server. In addition, a list can be displayed that shows all accessible OPC items. This feature makes the diagnosis of OPC DA/UA access easier.

Related Stories

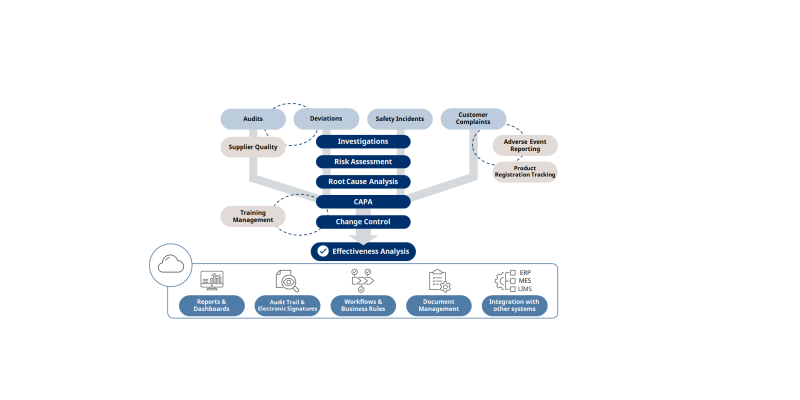

Yokogawa unveils OpreX to accelerate DX in quality assurance

The audit trail and user management methods employed by this system comply with global pharmaceutical regulations, leading to improved integrity in the handling of data for quality assurance proce..

Read more

Yokogawa unveils OpreX Subsea system to detect damage at offshore wind farms

Subsea power cables at offshore wind power generation facilities are prone to faults and damage from natural disasters and accidents, and damage to these cables can lead to significant financial los..

Read more

OPC UA: The language of Industry 4.0

Industry 4.0, which links the IT (Information Technology) and automation systems, requires many machines and devices to communicate with each other for seamless operation. OPC UA, an information arc..

Read moreRelated Products

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.

Heat Exchanger Scale Removal Compound -hesr-300

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy