Schedule a Call Back

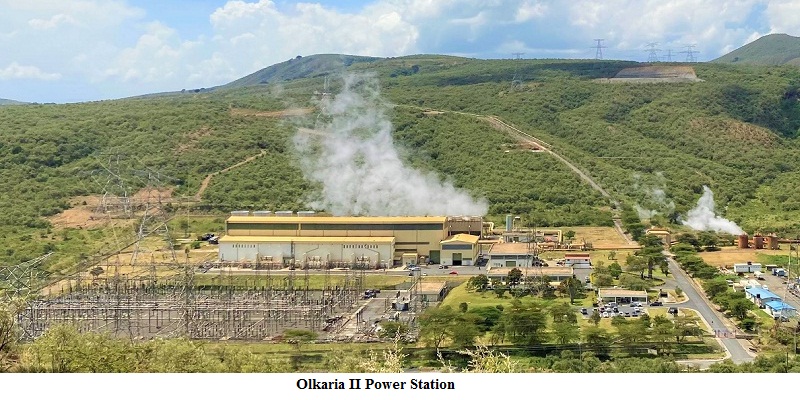

Yokogawa installs IoT system at Kenya’s Olkaria Geothermal Complex

Industry News

Industry News- Sep 12,22

Related Stories

Musashi India Expands Bengaluru Plant to Boost Transmission Output

Musashi India has completed Phase 2 of its Bengaluru plant expansion to scale production.

Read more

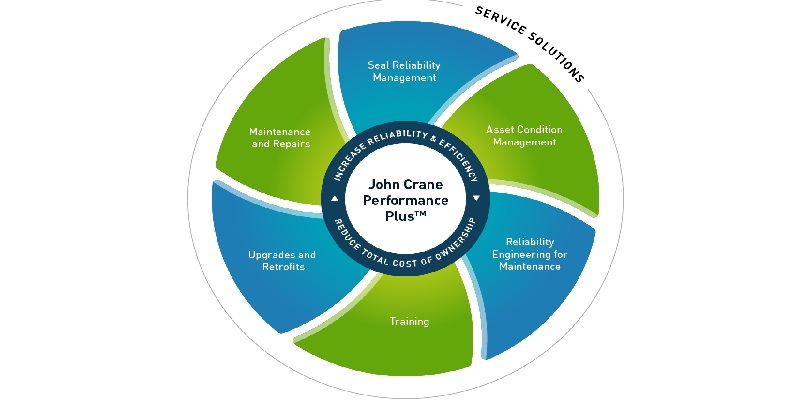

John Crane launches Performance Plus to drive a new era of operational excellence

The framework combines data-driven monitoring, expert consultancy and hands-on training to help customers reduce downtime, boost reliability and strengthen long-term resilience.

Read more

Ester Industries Reports 7% Growth in Revenue, Focuses on Sustainability & Expansion

With growing demand for Polyester Film, IP protection for certain marquee products in Specialty Polymers segment, and focus on products promoting recycling and sustainability, we are confident to co..

Read moreRelated Products

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.

Heat Exchanger Scale Removal Compound -hesr-300

Hi There!

Now get regular updates from IPF Magazine on WhatsApp!

Click on link below, message us with a simple hi, and SAVE our number

You will have subscribed to our Industrial News on Whatsapp! Enjoy