Schedule a Call Back

UCIMU: A positive 2016 for the Italian machine tool industry

Industry News

Industry News- Nov 30,-1

Cinisello Balsamo, January 2016. The Italian machine tool, robot and automation manufacturing industry closed the year 2016 registering a plus sign for a good part of the economic indicators and gets ready for a 2017 of further growth. This was the message conveyed by President of UCIMU, Massimo Carboniero a few days ago on the occasion of the year-end press conference of UCIMU-Sistemi Per Produrre – the Italian machine tool, robots, automation systems and ancillary products (NC, tools, components, accessories) manufacturers' association.

“Great work was carried out by the Government authorities. With the Industry 4.0 Plan, they created a concrete programme of industrial policy, capable of ensuring the competitiveness improvement of the Italian manufacturing industry,” said Massimo Carboniero.

As evidenced by the preliminary year's data processed by the Studies Dept & Business Culture of UCIMU, in 2016 production increased to 5,480 million euro, recording a 5% upturn versus the previous year. A definitely positive trend was reported with regard to the deliveries by the Italian manufacturers in the domestic market, grown to 2,205 million euro, i.e., 20.5% more compared with the previous year. On the other hand, export decreased, marking a -3.3% and reaching only 3,275 million euro, due to the weakness experienced in some major destination markets of the Italian product offering.

Based on the ISTAT data processing by UCIMU, in the first nine months of the year (latest available survey), the main destination countries of the "Made in Italy" in the sector turned out to be: Germany 260 million (-1%), United States 247 million (-9.1%), China 222 million (-9.7%), France 158 million (+23.6%), Poland 90 million (+3.5%), Mexico 76 million (+37.1%), Spain 75 million (+8,5%); Turkey 64 million (-4.4%), United Kingdom 58 million (-33%), Russia 57 million (-60%).

Consumption showed a good trend thanks to a 10.1% increase, totalling 3,685 million euro. It is the third consecutive year of double-digit growth, as a testimony to the recovery of the Italian market, which has finally started again to invest in production technologies.

The year 2017 will also be positive for the Italian industry of the sector: according to the forecasts there will be a growth for all the main economic indicators. Production will rise to 5,700 million euro (+4%), thus getting closer to the record-breaking value of 6 billion euro registered in 2008.

Exports, expected to grow by 1.7%, will attain 3,330 million euro. The positive trend of consumption will also go on: it should rise by 6.9 %, to 3,940 million euro, driving the deliveries of manufacturers, which should reach 2,370 million euro (+7.5%), as well as imports, expected to amount to 1,570 million (+6.1%).

“Now, with the Industry 4.0 Plan, included in the already approved Budget Law 2017 – stated Massimo Carboniero – the Government gave the country a well-structured and comprehensive programme of industrial policy. Confirmation of the Super-Depreciation at 140%, introduction of the Hyper-Depreciation at 250%, re-financing of the New Sabatini Law, increase from 25% to 50% of tax deductions for R&D activity are the pillars on which the programme is founded. With this plan, Italian enterprises can rely on a series of measures aimed at favouring the improvement of their competitiveness. These measures can further boost the consumption of machinery and innovative technologies for factory digitalisation.”

“In particular,” went on Massimo Carboniero, “with the re-confirmation of the Super-Depreciation at 140%, the companies using machinery and production systems may rely on an incentive to renew their total machinery and increase the number of machines installed in their industrial plants, which often turned out to be obsolete based on recent surveys. On the other hand, the Hyper-Depreciation at 250% is aimed to support the enterprises' technological and digital transformation according to the “Industry 4.0” model. The provision is indeed intended to stimulate the introduction and spread of systems linked to one another within the same factory or between systems of a single factory and other external systems”.

“On the basis of these clear and evident differences, the machine tool manufacturers will have to take active steps to understand and keep up with new and different customers' requirements in the best way, while providing, if necessary, an upgrade of the supplied technologies, so that they can ensure interconnectivity,” said President of UCIMU in conclusion.

Related Stories

Zen Mobility launches new pod variants- ThermoFlex and LoadMax

Equipped with cutting-edge technologies such as telematics, IoT integration, geo-fencing with remote vehicle locking, trip data monitoring, and battery state-of-charge (SOC) tracking, these variant..

Read more

Igus develops slewing ring bearing made of wood and plastic

Igus develops slewing ring bearing made of wood and plastic

Read more

Igus develops slewing ring bearing made of wood and plastic

The new slewing ring bearing made of wood-plastic composite (WPC), presented by igus at Hannover Messe 2024, strikes a good balance between strength, durability and environmental friendliness with a..

Read moreRelated Products

Welding Automation

Drupe Engineering Private Limited is offering a wide range of welding automation.

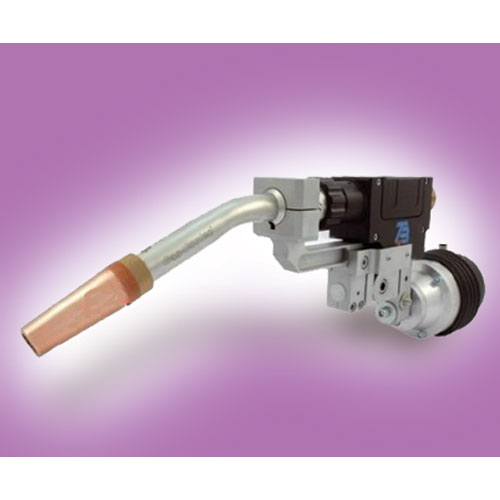

Robo Mig Tbi Robot Welding Torches

Mehta Sanghvi

& Company manufactures Robo MIG TBI robot welding torches.

Heavy Duty Goliath Crane

Ganesh Engineering Co manufactures and supplies a broad array of heavy-duty goliath crane.