Schedule a Call Back

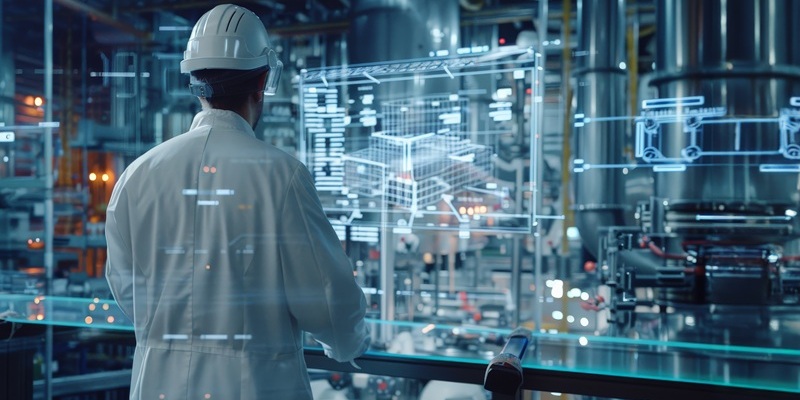

Top 3 CNC machines smart factories rely on

Articles

Articles- Apr 27,23

Related Stories

B&R presents new automation engineering experience with Automation Studio Code

DevOps integration ensures smooth, efficient and reliable software delivery pipelines.

Read more

6 Nonnegotiable requirements for your smart factory transformation

The smart tech world is seemingly never-ending, but a few essential staples create an unshakable foundation. Here, Emily Newton suggests six essential ingredients for a transformation to smart facto..

Read more

Addverb ropes in Infineon Technologies to deploy BLE safety in robotic fleet

This collaboration aims to integrate Bluetooth Low Energy (BLE)-based communication systems into Addverb’s robotic fleet, significantly advancing safety protocols and setting new benchmarks in sma..

Read moreRelated Products

Turning Tools

Duracarb Cutting Tools offers a wide range of Turning

Tools.

Carbide Burrs

SRT Industrial Tools & Equipments offers a wide range of carbide burrs.

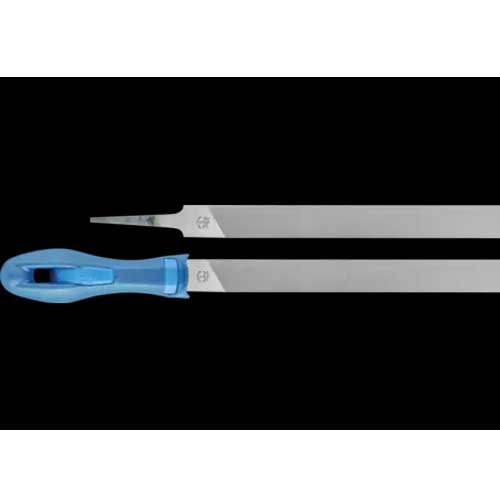

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.