Schedule a Call Back

TAGMA’s president encourages companies to participate at Die Mould India 2024 Exhibition

Articles

Articles- Jan 29,24

Given the global turmoil, how was the performance of the Indian die and mould industry in 2023? What is your expectation for 2024?

The Indian die and mould industry performed exceptionally well in 2023, despite the global turmoil. The toolmakers demonstrated their resilience, innovation, and competitiveness by expanding their capacity and onboarding new customers. The demand for tools came from many new industries such as aerospace, defence, electronics, consumer goods, among others, which opened up new opportunities and challenges for the industry.

We are optimistic about 2024, as many toolmakers have confirmed good order books and are planning to invest more in the infrastructure. We expect that the latest smart manufacturing solutions, such as Industry 4.0, IoT, AI, etc, will find their place in the Indian tool rooms and enhance their productivity, quality, and efficiency. We are confident that the Indian die and mould industry will continue to grow and excel in the global market.

Why are moulds & dies crucial for the success of the manufacturing industry?

Moulds and dies are crucial for the success of the manufacturing industry because they are the tools that shape and form the products that we use every day. Die and mould are often referred to as the mother industry because they help in creating many products, such as automobiles, appliances, electronics, medical devices, etc. The quality of the tool is directly proportional to the quality of the end product, which is why it is extremely important to have good quality moulds and dies. Good quality moulds and dies ensure accuracy, precision, durability, and efficiency of the products, and also reduce the cost and time of production. Therefore, moulds and dies are the key factors that determine the competitiveness and profitability of the manufacturing industry.

What are key challenges before the die and mould industry?

Indian tool rooms grapple with many challenges. Let’s take a look at the ones that the report has highlighted:

Also, will the growing demand for electric vehicles (EV) and technologies like Additive Manufacturing (AM) affect the demand for dies and moulds?

The emergence of electric vehicles (EVs) is a significant and welcome development for toolmakers. While it is true that companies focusing on traditional engine and powertrain components may experience an impact, the shift to EVs also brings forth a plethora of opportunities for toolmakers, specifically in the realm of engineering plastics.

As EVs become more prevalent, there is an increasing demand for components made from advanced engineering plastics. This includes a wide array of parts such as interior components, body panels, and various structural elements. Toolmakers are poised to play a crucial role in providing the necessary tools for manufacturing these intricate and precise plastic components.

Furthermore, the battery technology integral to EVs presents another avenue for toolmakers. Tools required for the production of battery-related components and housings are expected to witness a surge in demand. This presents a strategic opportunity for toolmakers to diversify their offerings and cater to the evolving needs of the automotive industry.

Discussing 3D printing, we perceive this technology as a significant value addition to the tooling industry. Particularly, tasks like designing conformal cooling systems are optimally executed through 3D printing. This technology offers a unique capability to intricately design and produce complex shapes that traditional manufacturing methods might find challenging. Moreover, 3D printing stands out when there's a requirement for producing parts in small quantities. The flexibility and cost-effectiveness of 3D printing make it a suitable choice for small-batch production, enabling industries to efficiently meet specific demands without the constraints of mass production. This not only streamlines the manufacturing process but also provides a more sustainable and resource-efficient solution, aligning with contemporary industry demands. As technology continues to advance, the role of 3D printing in tooling is likely to expand, bringing about further innovation and efficiency improvements in the industry.

What kinds of new opportunities can the die and mould industry tap in different industrial sectors like automotive, defence, railways, renewable energy, etc?

The automotive sector has consistently been the predominant consumer of tools globally, contributing to over 60 per cent of our business. Nevertheless, we are witnessing a notable surge in various industries such as aerospace, defence, packaging, toy manufacturing, electronics, and home appliances. Anticipating substantial growth, we foresee these diversified sectors playing a significant role in our expansion in the forthcoming years.

How is TAGMA gearing up for Die Mould India 2024 (DMI 2024)?

Die mould India being the largest exhibition for tool and die makers in India it always attracts huge crowed from all over India and this year is no different. Looking at the kind of registrations we have received till now and excitement about the expo among the industry colleagues, we are confident that this edition is going to be the biggest one.

On the eve of DMI 2024, any message to the industry...

2023 has been nothing short of remarkable for the Indian tooling industry. We've witnessed growth and achievements, and as proud toolmakers, we must carry this excitement into the promising year that lies ahead, 2024.

As per recently released data in the Indian tooling report the estimated market size of Indian tooling industry is approximately 23,600 crore, it's evident that our industry holds great potential. However, there's room for improvement, especially when considering that around 34 per cent of the tooling demand is currently met through imports. Approximately 80 per cent of these imports are from China, South Korea, Japan, and Taiwan. We all need to target these areas collectively and reduce the imports.

One avenue through which we can collectively showcase and leverage our capabilities is the upcoming Die Mould India exhibition. I encourage each one of you, as well as your respective companies, to actively participate and make this event a grand success. It's not just an exhibition; it's a platform where ideas flourish, partnerships are forged, and the future of Indian tooling takes center stage.

So, let's gear up for the challenges and opportunities that 2024 holds. Together, we can shape an even more successful and resilient future for the Indian tooling industry.

Related Stories

Technip Energies Wins Two Major BPCL Contracts

Technip Energies has secured two large contracts from BPCL for polypropylene, Butene-1 and PRFCC projects at the Bina and Mumbai refineries, strengthening India’s refining and petrochemical capaci..

Read more

Jindal Stainless launches fabrication unit in Maharashtra

The company plans to expand its fabrication facility to other regions in India, with Mumbai fabrication unit will also be solar power enabled in its next phase.

Read more

Jindal Stainless Launches First Stainless Steel Fabrication Unit in Mumbai

It will also serve as a centre of excellence for skill development, preparing India’s workforce for sustainable infrastructure projects.

Read moreRelated Products

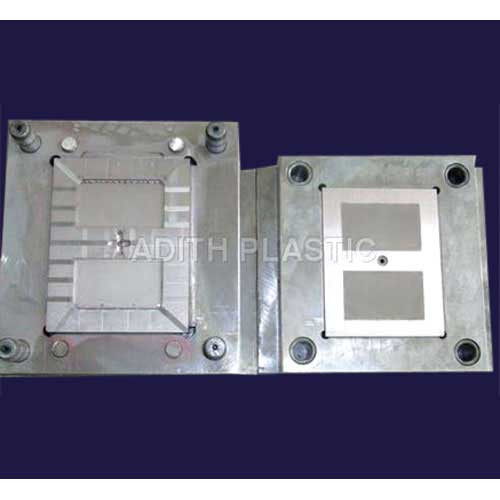

Industrial Moulds

Adith Plastic offers moulds for industrial electronic parts.

Industrial Plastic Moulding Dies

Adith Plastic offers a wide range of industrial plastic moulding dies.

Component Moulds

Innovative Moulds & Dies offers a wide range of plastic component moulds. Read more