Schedule a Call Back

"Sustainability has become centre-stage"

Interviews

Interviews- Sep 02,22

SKF - a leader in the bearing business - offers solutions that reduce friction and CO2 emissions while increasing machine uptime and performance. In the first quarter of FY 2022-23, SKF India delivered solid results with revenue increasing by 52% and profit before tax increasing by 66% year-over-year. According to Manish Bhatnagar, President - India and Southeast Asia, SKF Group, the company is actively strengthening its competitive position within each of its business segments and investing in the future. In this interview with Rakesh Rao, Manish Bhatnagar elaborates more on global & domestic economy and strategies adopted by SKF India to maintain its growth momentum.

SKF registered a strong performance in FY22 in Q1 FY23. Despite a volatile environment, how did SKF India manage to keep growth momentum going?

While the operating macroeconomic environment looks uncertain, delivering growth remains our priority. Our steadfast commitment to delivering on our strategy of intelligent and clean growth, combined with our focus on improving operating efficiencies, optimising costs through digitalization, driving customer-centricity, and investing in our people’s capabilities have enabled us to maintain our growth momentum.

Additionally, strong demand in the economy, positive cash flow momentum, and pricing actions across our products and solutions helped us deliver robust results. Looking ahead, we continue to work closely with our customers across automotive and industrial segments to meet their evolving needs. We have also invested heavily in our e-marketplace capabilities to further strengthen our distribution network across the country, create awareness about our products & solutions, and prevent counterfeiting.

What are key challenges on the path at present?

While we have seen the domestic economy navigate macro headwinds and register strong growth, challenges remain in the external operating environment. For instance, the global geopolitical climate remains uncertain, and most economies are still recovering from the pandemic blues. Global trade lines too haven’t recovered fully. Rising oil and commodity prices weigh on our margins, though we have seen prices of steel and other essential commodities starting to settle.

Another area of concern is the lingering freight issues in the country. With the sudden coal shortage that gripped the country earlier this year, most of the freight vans were allocated to ferry coal across the country. This has resulted in a severe shortage for other industries. However, we are confident that the situation will gradually improve over time as coal shortage recedes. The government too, has announced a series of measures to mitigate the issue.

How SKF intends to meet the demand for smart and intelligent products and solutions for customers?

Sustainability has become centre-stage and companies across industries have announced their net-zero targets. In this backdrop, there’s a razor-sharp focus on smart and intelligent products and solutions to support clean growth. As a customer-centric organisation, all our products and solutions are aimed at helping customers achieve the highest potential with their equipment. Here are few ways in which we leverage our engineering and technology capabilities to deliver value to our customers.

With remanufacturing, we are increasing the life of our bearings and helping customers reduce their operational costs. Further, it also reduces the strain on natural resources as we re-engineer existing products instead of manufacturing afresh. Our Rotating Equipment Performance (REP) business model offers onsite support to assess product performance, detect anomalies, maintain high output, and reduce downtime. RecondOil, another ground-breaking solution, enables a circular economy with our oil-as-a-service contracts. The technology helps us purify the oil, down to nano level – with all original properties intact. This too reduces the operational cost, strain on natural resources, and carbon emissions.

In addition, our next generation bearings like ceramic and magnetic bearings support industry megatrends on sustainability and electrification. We are also developing a series of low noise and low friction bearings to support faster adoption of EVs and other applications. Our sensor technology, integrated with bearings helps customers maximize output by evaluating usage data and optimizing equipment performance.

Sustainability is a buzzword in industries. What steps are you taking to (A) reduce SKF India's carbon footprint, and (B) help end-use industries (your customers) to achieve their green goals?

SKF’s heritage lies in products that reduce friction and thereby enable a more sustainable industry. We remain focused to achieve net zero GHG emissions across all our production facilities, all over the world by 2030 and achieve net zero emissions across our supply chain, from raw materials to delivery of products and solutions by 2050. From transitioning to renewable energy to power our factories, designing LEED certified offices, using sustainable and low emission raw materials in our products and solutions, and improving manufacturing processes, we’re undertaking several initiatives to reduce our carbon footprint.

Our strategy of clean and intelligent growth also indicates our resolve to help customers achieve decarbonisation. In addition to designing products which are low on weight to reduce friction, we also help customers select the right bearing for their applications. We recently launched a new, freely available, tool to help the industry to better understand and address their carbon emissions. The tool provides a detailed view of the specific carbon emissions for the bearings and how the customer’s application can be optimised to reduce energy consumption and corresponding emissions in the future. Leveraging our solution factories and Remote Diagnostic Center (RDC), our customers can monitor the bearing for early defects and adopt solutions like re-manufacturing to reduce downtime.

Through our lubrication technologies, we have developed green greases which reduce the starting torque by up to 40% in the bearings. The lubrication system also helps reduce wastage by monitoring requirement at various intervals. SKF’s sealing technologies helps customers reduce lubricant wastage due to leakages and achieve reliable bearing performance. With all of this and more, we will continue to focus on our mission to develop bearing technology and services that make rotation more reliable, more predictable and more sustainable – to help our customers face today’s extraordinary challenges.

What are your growth plans for SKF India?

We are actively strengthening our competitive position within each of our business segments and investing in our future. To realise our goals, we are expanding our presence in the railways, mining, and construction segment. The automotive segment has shown a sharp recovery and the industrial segment has picked up steam. We remain focused on sustaining the momentum in the long-term, including driving digitalization across the full value chain, transforming our business and our ways of working. We are excited by our growth potential and believe that by delivering against our new strategic priorities, and leveraging our vast product portfolio and knowledge, we will continue to create significant value for everyone associated with us.

Related Stories

Industry 4.0 gains momentum in India amid challenges

A recent study by the Indian School of Business (ISB) and Plugin Alliance revealed that 54% of Indian manufacturing companies are already implementing AI and analytics to enhance cost efficiency, pr..

Read more

Re Sustainability International acquires G3 Environmental

G3 Environmental’s businesses include Tee Environmental, Tee Recycling, and Envotek Engineering—companies renowned for their track record of excellence and robust client base in Singapore over ..

Read more

The Rise of India’s Construction Equipment Industry

Driven by increased government spending, rapid urbanization, technological advancements, and the 'Make in India' initiative, the RAHSTA (road) ahead for the construction equipment (CE) industry is b..

Read moreRelated Products

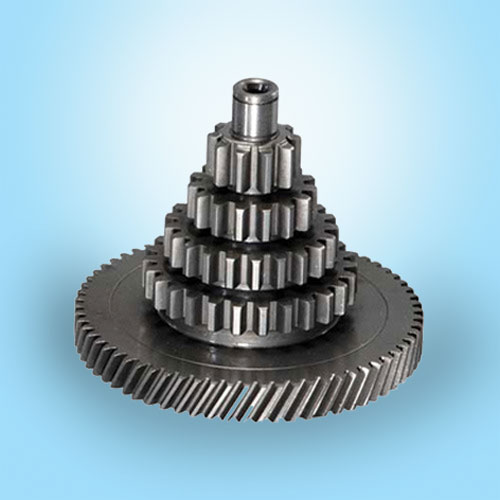

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Ground Spiral Bevel Gear

Bevel Gears (India) Pvt Ltd offers a wide range of ground spiral bevel gear.

Bearings

ARB Bearings is a manufacturer of a wide variety of bearings. Read more