Schedule a Call Back

SUHNER India offers robotic automation solution

Industry News

Industry News- May 26,22

We develop robotic material removal solutions, end-effectors, abrasive materials, process know-how and accessories, easy to implement and easy to adapt thanks to the perfect interaction between them.

Our goal is to increase the usage of robots for productions with high part variability thanks to cost effective solutions and a reduced set up time. Food & Pharma industry, metal construction, weld removal, surface sanding are typical segments and applications.

Skilled Labour

Metal processing quality strongly depends on the manual skills of each single operator. Qualified labour force is shrinking, with fewer and fewer workers prone to accept this heavy and dangerous job. Manufacturers worldwide are struggling to find workers. This is well-in-line with the Megatrend of Sustainability, that is not only limited to taking care of the environmental impact, but it is also aiming to ensure a good life quality for everyone.

Productivity

The metalworking industry strongly relies on workers for material removal operations such as grinding, polishing, and deburring.

It currently represents a bottle neck towards a more efficient and more sustainable production.

Virtually, any welded frame or component requires post processing of material removal and metal finishing.

This can account for up to two-thirds of the production time and can be affected by operator absenteeism, reduced productivity of operators and quality inconsistencies, not to mention the risk of injuries and operator’s body fatigue.

Production cost

The production of metal structures requires a lot of man-hours, to remove welds, burrs and obtain a high-quality finishing product. Total production costs are also heavily affected by the risk of injuries that translate into costly workman’s compensation, inefficient energy consumption and quality issues.

Especially in sectors such as medical, pharmaceutical and food, where the surface quality is critical and regulated, to achieve hygiene and cleanness requirements, this work can cost up to half of production costs.

An operator is more flexible and adaptable than any machine, but he is also the most inconsistent. Fatigue due to hard work, skills, methodology and motivation are some of the main causes of quality variation for many of our customers.

To improve the efficiency of grinding operations towards a more sustainable production, one can opt for SUHNER's robotic automation solution.

Contact

SUHNER India Pvt Ltd, Bangalore, India

Mobile: +91 99723 00933

Web: www.suhner.com

Related Stories

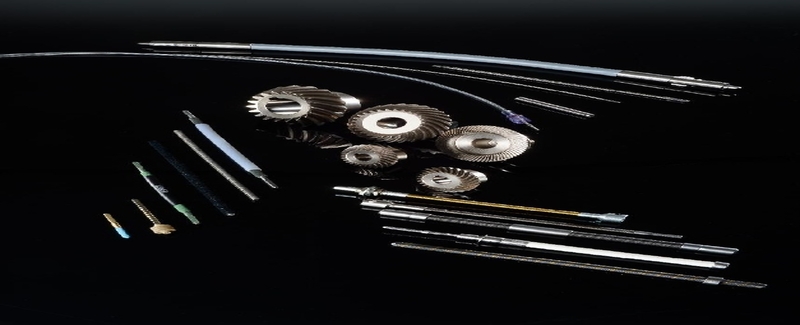

Suhner’s Transmission Division offers multifaceted, flexible shafts

For comfort elements in vehicles and challenging applications in many other industrial areas, flex shafts facilitate new approaches to the drive concept.

Read more

Suhner’s innovative drive supports global business

With its strong global focus, the Transmission Division of the Suhner Group supports a vast array of high-tech companies.

Read more

Suhner increases production capacity with process optimisation

REGE Motorenteile GmbH produces cylinder housings for a German car manufacturer. When housings are manufactured, the bearing points for the camshaft require some additional milling.

Read moreRelated Products

Bmt Tool Disc and Tool Holders

Prominent Machine Tools offers a wide range of BMT tool disc and tool holders.

Superbolt Tool

Nord-Lock India Pvt Ltd offers a wide range of Superbolt

tool.

Cbn and Diamond Tools

Krebs & Riedel Abrasives India Pvt Ltd offers a wide

range of CBN and diamond tools.