Schedule a Call Back

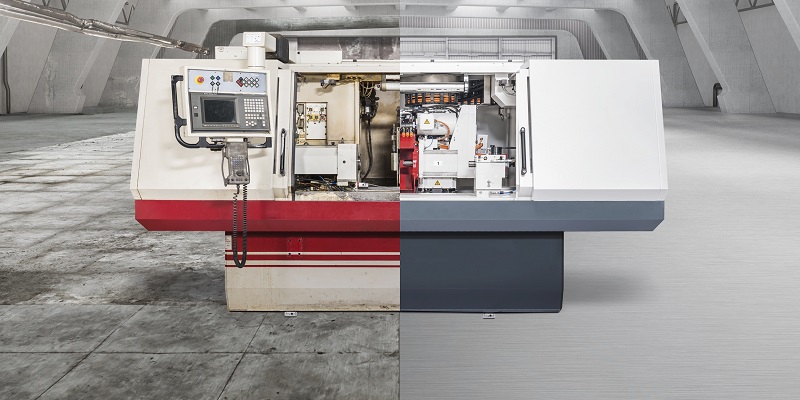

Studer’s renewed cylindrical grinding machines

Industry News

Industry News- Aug 08,24

- Machine bed: completely overhauled, the knobbed pattern is milled off, the guideways recast, and the base repainted.

- El. Enclosure: replacement of the wear parts in the electrical cabinet

- Pneumatics: new valves, hoses, and filters.

- Hydraulics: new hydraulic and lubrication system, all valves and hoses are replaced.

- Workhead: completely overhauled.

- Wheelhead: completely overhauled.

- Tailstock: completely overhauled.

- Axes: table as good as new, installation of a new recirculating ball screw and bearings.

- Machine enclosure: sandblasted, new topcoat, color according to STUDER design or customer preferences.

- Control system: existing controller retained.

- Delivery: always with careful measurement of the geometrical tolerances of the new machine, including test protocols.

- Loan machine: we can provide a loan machine on request.

- New original CE certificate

- Automation solutions on request

Related Stories

Studer Strengthens Global Position Amid Challenging 2025 Markets

Despite geopolitical headwinds, Studer expanded market share, launched key innovations, set service records and expects continued growth in 2026.

Read more

Evermore Elevates Precision Manufacturing with STUDER Machines

Evermore is strengthening its precision manufacturing capabilities through long-standing collaboration with STUDER, leveraging high-accuracy grinding technology to boost quality, efficiency, and com..

Read more

HARTING views India as a high-potential market: Jörg Scheer

In this interaction with Rakesh Rao during Hannover Messe 2025, Jörg Scheer, MD of HARTING Electronics & HARTING Customised Solutions, highlights on emerging opportunities with the rise in electrif..

Read moreRelated Products

Precision Cutting Tools1

S S Trading Corporation offers a wide range of precision

cutting tools.

Slotting Head Unit for All Cnc Turn Mill Centers

Sphoorti Machine Tools Pvt Ltd offers a wide range of

slotting head unit for all CNC turn mill centers.

Slotted Tool Disc and Tool Holders

Prominent Machine Tools offers a wide range of slotted tool disc and tool holders.