Schedule a Call Back

Schmersal showcases new automation, safety solutions for intralogistics

Articles

Articles- May 27,23

In intralogistics, the requirements on productivity and system reliability are extremely high-customers expect ever more rapid and reliable order processing, which means that processes are increasingly being automated. On top of this, there is high potential for danger in internal warehousing and transport. Accidents not only endanger the health of employees, but negatively affect operational processes and give rise to high costs. When developing new automation and safety solutions for intralogistics, Schmersal always keeps two things in mind – safety and productivity.

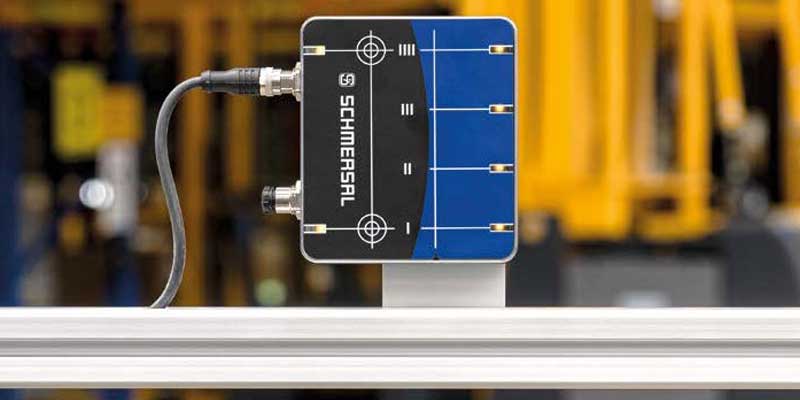

Cost-effective and maintenance-free, the SSB-R magnet track sensor box

One solution to improve the productivity of internal material flows is being showcased by Schmersal at Hannover Messe 2023 – the SSB-R magnet track sensor box, which is designed to monitor the speed and position of electric monorail conveyors.

Solenoid interlocks

Electric monorail conveyors are used in various industries to aid the transport of work pieces and materials of varying kinds. They require no form of aisle setup, which makes them considerably more efficient and faster when compared to stationary conveyors, and helps to save floor area in assembly and storage. An electric monorail conveyor system will always have multiple trolleys operating on conveyor system. In some areas, these trolleys will move at speed, while in others they will move more slowly and stop at defined points. Consequently, speed and position monitoring of each individual trolley are essential. Until now, magnet sensors have been used as the solution. The new SSB-R magnet track sensor box from Schmersal now carries out these functions with significantly improved precision.

The sensor box allows up to four parallel and independent magnet tracks to be queried. It captures the magnetic field of the actuators and changes the signal status when they are passed. This level change, which occurs even in the event of rapid pass-by, is maintained until the next activation. If a control system is connected, it uses the signals to determine the position and route section of the sensor box and regulates factors such as the speed (rapid pass-by/crawl speed) or stopping position of the drive motor.

The sensor box is available in four versions. The version designated SSB-RH is equipped with additional sensors on two tracks and uses a high level signal (100 ms). These properties ensure high positioning accuracy, allowing a trolley to be brought to a stop at its desired stopping position with accuracy of around 1.5 mm. This is of particular benefit at robot workstations, where components need to be positioned with extreme accuracy. With the second positioning track, users can define a stopping zone with careful precision, for example, start and end positions for overtravel.

SSB-R magnetic track sensor box

An additional benefit for productivity is magnetic signal storage, which retains signals in the event of a power failure; thereby enable a rapid restart of operations. The sensor box is not only a helpful aid for simplified assembly and more accurate trolley positioning when planning new systems – as the magnet switches and tracks are installed with the usual spacing of 30 mm, the box can easily replace four individual magnet switches, for example, those of the BN325 and BN310 series from Schmersal, with only minimum assembly effort and improved positioning accuracy.

It also offers flexible application options as there is a range of other conveyor systems that are supplied with energy and signals via busbars – including storage and retrieval devices, floor-based skids and shuttles on the individual levels of shuttle AKLs (AKL is automatic small parts warehouse). On these and other systems, use of the magnet track sensor box offers the same benefits as on electric monorail conveyors.

Networked safety solutions

Material flows at major logistics sites, such as regional warehouses operated by food discounters or goods distribution centres operated by contract logistics providers, are largely automated. There are special requirements in place for the safety of machinery, as these automated systems tend to be extensive and have numerous interfaces with personnel, such as at transfer points. Networking of safety switchgear can offer a solution in these situations. This means the replacement of traditional individual wiring of each switchgear device with efficient, network-like wiring concepts, for which there are various options.

Safety Fieldbox allows the connection of up to eight safety switching devices

Palletisers handle heavy loads at high speed. To protect personnel from rapid movements, such as those performed by gantry robots, protective fences are used around the operating areas occupied by people and robots and fitted with a guard door at a minimum, the position of which needs to be monitored to ensure safety. Designers of these should ideally opt for a solenoid interlock, such as the AZM201 from Schmersal. This interlock keeps the guard door locked until hazardous movements and overtravel have ceased. This helps to ensure interruption-free operations, as palletisation cannot be stopped by the guard door being opened. This is all the more important when you consider that palletisers tend to be integrated into networked production and packaging processes.

Solenoid interlocks, as well as many other safety components from Schmersal, can be equipped with an integrated interface for the AS-i Safety at Work safety bus system for easy integration into a safety circuit. The AS-i-Safety standard not only facilitates rapid installation with minimal wiring effort, but also maximum flexibility, for example in the event of system modifications or new requirements and safety requirements.

Another advantage is the comprehensive range of diagnostic functions. These make for more rapid identification of the source of error in the event of irregularities or faults. This is particularly beneficial in the case of extensive, complex systems, and can help to reduce downtime significantly. For these reasons, many intralogistics systems that Schmersal equips with safety systems are networked using AS-i SaW.

Connection via Safety Fieldbox

The Safety Fieldbox (SFB) system can also be used as an alternative to the AS-Interface Safety at Work. A Safety Fieldbox enables field connection of up to eight safety switchgear devices of different types. Electromechanical and electronic terminal devices occupy just one device connection each. Both the safety and operational signals are captured and connected to higher-level control modules via Europe’s most commonly used bus system – PROFINET/PROFIsafe.

New SD 4.0 bus system

If the user only wishes to capture and evaluate operational, that are non-safety-related signals, SD 4.0 offers a third option. It is the latest manifestation of a bus system developed by Schmersal to allow electronic safety sensors and solenoid interlocks to transfer comprehensive status and diagnostic data to a higher-level machine control system. A key difference of the SD 4.0 system over previous SD bus systems is the significantly improved networking capability with higher levels. A prerequisite for this is the connection to OPC UA as a standardised protocol for M2M communication, which has the advantage of better visualisation of diagnostic information collected in the field, and better access via mobile devices such as tablets and smartphones. This enables implementation of predictive maintenance concepts.

Quote

“Intralogistics includes complex processes and operating areas with differing potential for danger. Schmersal offers the ideal solution for every potential hazard point, whether as an individual product or as a holistic system solution, all tailored to the specific application. Within this, our objective is always to raise system availability,” said Marcel Bogusch, Logistics Industry, Manager, Schmersal Group

Related Stories

Caliber Interconnects unveils AMRs and robotic handlers

Caliber’s AMRs are AI-driven, customisable automation solutions engineered for industries such as warehouse logistics, manufacturing, e-commerce fulfilment, healthcare, and automotive

Read more

Caliber Interconnects showcases AMRs and robotic handlers at Automation Expo

Caliber’s Autonomous Mobile Robots (AMRs) are AI-driven, customizable automation solutions engineered for industries such as warehouse logistics, manufacturing, e-commerce fulfilment, healthcare, ..

Read more

Daifuku unveils advanced manufacturing and innovation facility in Hyderabad

This facility strengthens the Indo-Japanese bilateral relationship, with a focus on knowledge transfer, skill development, and co-creation.

Read moreRelated Products

Dock Leveller

Besto Material Handling Equipments offers a wide range of dock leveller.

Multi Tire

SCI Storage Solution offers a wide range of multi tire.

Industrial Lifting Equipment

Rana Material Handling Equipments Pvt Ltd offers a wide

range of industrial lifting equipment.