Schedule a Call Back

Robust cybersecurity regulations offer an organised framework: Praveen Kulkarni

Industry News

Industry News- Dec 03,24

Related Stories

SME Magazine Honours India’s Fastest Growing Engineering Companies at NSE

The Smart Manufacturing & Enterprises (SME) Conference & Awards 2026 - held on February 11, 2026 at National Stock Exchange (Mumbai) - highlighted resilience and technology as the cornerstones of In..

Read more

MIC Electronics Signs MoU to Enter Refurbished Electronics Segment

MIC Electronics signs an MoU with Refit Global to evaluate entry into the refurbished and circular electronics market, with due diligence in final stages.

Read more

Schneider Electric Opens Liquid Cooling Factory in Bengaluru

Schneider Electric launches its first Motivair liquid cooling plant in India, strengthening local manufacturing for AI-ready, high-density data centres and boosting export capabilities.

Read moreRelated Products

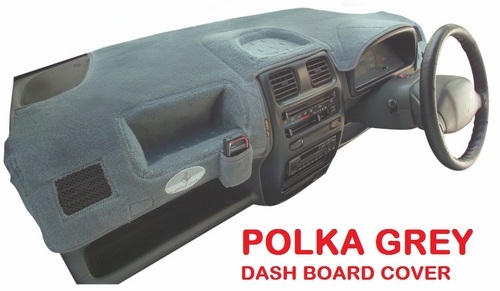

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.