Schedule a Call Back

Phoenix Contact offers sensor-free drive monitoring up to SIL 3 and PL e

Articles

Articles- Jun 30,23

The new PSR-MM35 safety relay module enables the realisation of efficient safe-motion solutions that are suitable for both stationary and mobile machines. To this end, the safety functions STO (Safe Torque Off), SLS (Safely Limited Speed), SMM (Safe Speed Monitor), and SSR (Safe Speed Range) are integrated in the over-speed safety relay. This device makes direct, sensor-free, and safe motion monitoring even more of a technically and economically attractive alternative to the use of non-contact, rotary, and linear safety sensors than ever before.

When implementing safe-motion concepts, fewer components also means less complexity. A motion monitoring system that is easy to install and measures directly at the drive, and which does not require any external encoders, allows controllable engineering for machine builders and integrators while implementing safety functions. Additional requirements on devices for sensor-free, safe drive monitoring include a reduced space requirement in the machine’s control cabinet or in a vehicle’s on-board control box, an intuitive configuration interface, fast commissioning of the safe-motion application, as well as high mechanical robustness and electromechanical interference immunity. Solutions that meet these requirements result in significant cost savings - not just through the omission of sensors. The safe PSR-MM35 over-speed safety relay therefore proves to be both a trailblazer and the state-of-the-art benchmark in terms of safely monitoring the motion and zero-speeds of drives and axes without sensor ballast.

Two-channel evaluation of the rotary field

The PSR-MM35 uses the physical principle of measuring rotating fields, such as those that occur continuously around the axes of rotation in AC and three-phase motors, for monitoring the safe speed of drives without the need for sensors. The safety relay module evaluates the rotary field across two channels and, using the measured values, can monitor the speeds and speed ranges of electrical drives without the need for sensors. This method of directly analyzing the motion information from drive mechanisms has proven to be very robust and reliable, in particular under harsh industrial operating conditions. This is because both mechanical interference factors - such as oscillations, shocks, and vibrations - and electromagnetic fields do not affect the rotary field measurement. On the other hand, non-contact, rotary, and linear safety sensors are often directly exposed to such external environmental influences. Furthermore, they do not always attain the highest safety integrity level (SIL) or the highest performance level (PL).

In contrast to this, the sensor-free PSR-MM35 over-speed safety relay - which, as a 12.5 mm-wide DIN rail module, takes up very little space in the control cabinet - satisfies the highest demands on safety with SIL 3 and PL e. To enable the safe shutdown of a machine or a mobile unit from automatic operation and to safely monitor the speed during setup, retooling, and service work, Phoenix Contact has integrated the safe-motion STO, SLS, SSM, and SSR safety functions into the over-speed safety relay.

Total machine shutdown not necessary

If the PSR-MM35 direct motion monitoring system detects an error, such as violations of the over-speed or under-speed limits or the violation of a defined speed range, the device activates the STO (Safe Torque OFF) safety function. Here, the drive is switched to the safe state and blocked for automatic starting or restarting. The drive mechanisms are only supplied with energy again for motion or rotations once the machine operator performs an acknowledgment.

To rule out any potential risk of injury during machine setup or maintenance, the operating speed is reduced by the drive regulator so that a manual intervention in the danger zone is possible. If the machine exceeds the reduced speed, the SLS safety function integrated into the PSR-MM35 safely switches off the drive. In practice, this function offers a significant advantage in terms of safety: when working on a machine, the machine does not necessarily have to be stopped completely, but can continue to run at a reduced speed. This supports the optimum availability and productivity of processes.

The sensor-free over-speed safety relay’s SSM safety function detects whether the speed of a drive falls below a specified limit value. The SSM function is used, for example, for monitoring mechanical guards on machines that have access or intervention openings protected by doors or hoods. The safety function ensures that the protective elements can only be opened once the specified speed of a drive or a machine axle is no longer exceeded.

The SSR speed monitoring function enables a speed corridor. That is to say, defined minimum and maximum speeds can be controlled at the same time. If the speed exceeds or falls below the speed limit values, the drive is safely shut down and stopped.

Ideal addition to the existing portfolio

The functions of the PSR-MM35 over-speed safety relay open up opportunities for new sensor-free concepts for the safety-related monitoring of electrical drives. At the same time, the safety relay module is an ideal addition to the Safe Motion portfolio from Phoenix Contact which, with the PSR-MM25 zero-speed safety relay for sensor-free zero-speed monitoring and the PSR-MM30 combined over-speed and zero-speed safety relay, enables all options for optimum sensor-free motion monitoring of drives and axlex.

Diverse fields of application

The fields of application for sensor-free safe drive monitoring with the PSR-MM35 are diverse. In machine tooling applications, drives can be controlled without sensors for safe motion when handling workpieces, changing tools, and during service work. In the harsh environment of woodworking machines, the reliability of the PSR-MM35 comes to the fore because of its failsafe feature when collecting the motion information in the servomotors. In power-operated bridge systems, speeds and zero-speeds can be monitored without sensors during the lifting and lowering of bridge elements weighing tons. The PSR-MM35 ensures that the motion speed limits are adhered to during the starting, normal, and braking phases.

For details, contact Phoenix Contact India Pvt Ltd, New Delhi, on Email: adverts@phoenixcontact.co.in

Related Stories

Phoenix Contact’s Trio Power: Reliable Power Supply for Material Handling

Phoenix Contact’s Trio Power: Reliable Power Supply for Material Handling

Read more

Revolutionising Auto Manufacturing with Open Automation Ecosystems

The adoption of open automation ecosystems and technologies, such as Phoenix Contact’s PLCnext, is revolutionising the automotive industry by addressing key challenges related to obsolescence, cyb..

Read more

BXL Enterprise is eyeing entry into Europe and Americas: Abhishek Bohra

In this interview, Abhishek Bohra, CEO, BXL Enterprise, explains why the company is a valuable partner for international companies looking to source from India

Read moreRelated Products

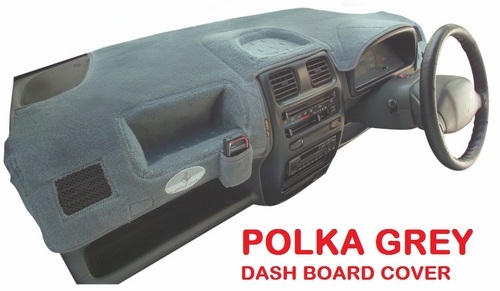

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.