Schedule a Call Back

Our manufacturing facility is compliant to EN stand

Articles

Articles- Jun 29,23

Can you brief us about your company?

Midas Safety is a leading global glove manufacturer with operations in 13 countries supporting sales in 56 countries. Midas investment in R&D and engineering makes it attractive for OEM to collaborate and bring out new innovative products and disruptive solutions.

Midas Safety Private Limited India is manufacturer and distributor of PPEs. In India, we manufacture knitted and dotted gloves, special purpose knitted gloves and sleeves, disposable masks, respiratory products and safety helmets. We offer a wide range of speciality gloves from our global portfolio and neck-up safety products for Industrial applications and personal safety.

We have sales and operations spread across India to serve customers through more than 80 distributors and over 1000 sub-dealers. We supply to end users in automotive, infrastructure and construction, oil & gas, aviation, chemical, electronics and pharma sectors.

Why personal protective equipment (PPE) is of paramount importance for companies today?

Though industries work diligently to eliminate risks, PPEs play a vital last line of defence against potential residual work environment risks. Selecting and adopting PPEs specified for the work place, understanding PPE performance parameters, rating and standards, continuous training and communication play an important role in creating a safe and thriving work place. People are the most important assets for any company. Protecting employees from workplace risks and Hazard is a regulatory and basic responsibility of management. Safety related work incident or accident have big impact on worker morale, productivity, brand value, stake holder perception of business and shareholders value.

Are factories today safer than say a decade back? How to ensure zero injuries at workplaces?

Industrial Safety has definitely improved over the last decade, with industry adopting OSH, ISI/EN standards of safety, understand best practices from industrial forums, improved awareness and incident reporting and learning from past incidents. Industry’s engagement with safety experts, employment of safety officers, access to better resources and practices, higher visibility of safety in conventional and social media, are all major improvements over the decade.

By nature of operations and risks certain industries have highly developed safety culture and governed strictly by regulations, for example oil and gas, pharma etc. In automotive industry safety culture has been driven by the OEMs who enforce such compliance on their tier-II and tier-III vendors too. However, many MSMEs do not have the expertise, resources/system to bring focus on safety and PPE usage. We must be looking to bring in dedicated industrial resources and consultants to assess, train and implement safety norms and reset the culture.

Zero injury is an ideal target. Holistic health and wellbeing of employees is of ultimate importance for companies. Use of PPE helps builds awareness and safety attitude, that enable behaviour change and building a safety culture at the individual level.

What factors are driving demands for PPEs in industries?

There are many factors that are driving the demand for PPE in Industry. Following are some of the prominent factors.

What trends are you seeing in the PPE industry?

Many domestic PPE manufacturers are investing and augmenting their existing capacities and reduce dependence on imports. New players have entered the Indian PPE industry (both domestic and international) to cater to the rising domestic demand and export opportunities. There is increase in awareness and adherence to standards, more options to select right PPE for the right applications. Large industries are looking to recyclability and reusability to meet their sustainability goals. There is also increasing awareness and use of PPEs by retail customers and sports enthusiasts. However, penetration of PPE’s across many segments also requires Government regulations and support, for example civic workers and MSMEs.

What are your growth plans for the company?

Over the last two years, we have expanded local manufacturing capacity and improved capability for knitted and dotted products, masks, and safety helmets. We have also invested in test equipment to meet the global standards in respiratory and head protection products. Over and above ISI, our manufacturing facility is also compliant to EN standards and many of our products are EN and ANSI certified. We plan to double our revenue by 2026.

Related Stories

High-Speed Clean Room Doors for Controlled and Regulated Environments

High-speed clean room doors are specialised industrial doors essential for maintaining controlled environments, providing an airtight barrier and enhance hygiene, safety, durability, and regulatory ..

Read more

HMS Networks Unveils Rugged N-Tron Switches for Mission-Critical Operations

The new NT100 unmanaged series offers exceptional reliability and performance for data acquisition, Ethernet I/O and process control.

Read more

Jindal Stainless Expands Slag Processing Capacity with USD 150 Million Investment

This initiative forms an integral part of Jindal Stainless’ long-term Environmental, Social and Governance (ESG) goals and its commitment to achieve Net Zero by 2050.

Read moreRelated Products

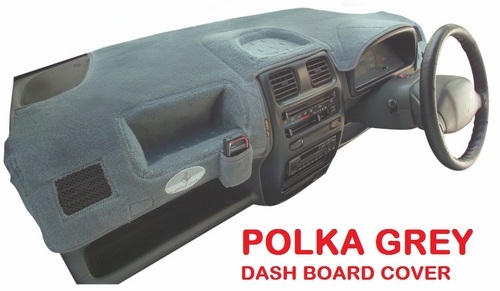

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.