Schedule a Call Back

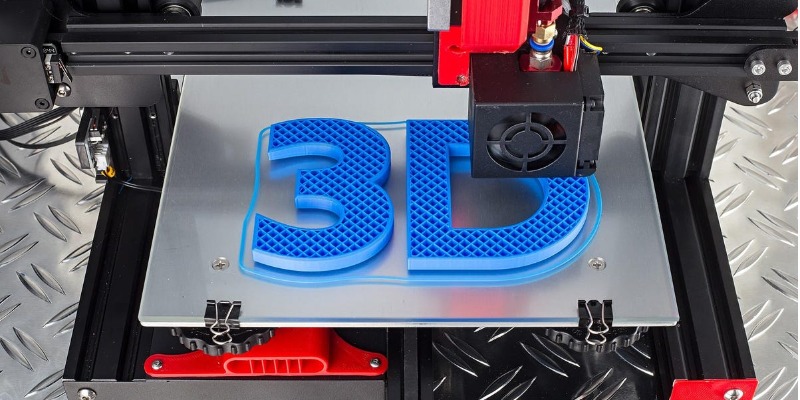

Metal 3D printing: Transforming manufacturing sector

Industry News

Industry News- Feb 23,22

“It is not the strongest of the species that survives, nor the most intelligent; it is the one most adaptable to change.†— Charles Darwin, a statement that still holds true in our current fast-paced world. Traditional manufacturing industries have historically been averse to changing their tried and tested ways of functioning. But with the looming threat of becoming obsolete in a world that is increasingly digital-driven, manufacturing industries have opened up to embrace the challenges of staying relevant.

Industry 4.0, also known as the Fourth Industrial Revolution, is fast becoming the much-needed change necessary to steer away from conventional manufacturing and leverage the benefits of digital technologies and advanced digital solutions to drive transformation. The purpose of Industry 4.0 is to integrate digital technologies with conventional manufacturing technologies to create a holistic cyber-physical manufacturing environment.

Traditional manufacturing industries are now incorporating digital solutions into their development, production, and supply chain. This disruptive approach comprises mainly of four solutions:

Role of additive manufacturing in Industry 4.0

The successful adaption of digital technologies is limited by the capabilities of the existing manufacturing systems. This makes additive manufacturing (AM) one of the vital components of this new revolution as it has inherently been digital-driven right from its inception, with the perfect combination of software and hardware driving its process.

Additive manufacturing is the process in which a high-power laser beam partially melts and fuses layers of metallic powder to form three-dimensional objects. Fully functional metal prototypes and three-dimensional end-use parts may thus be quickly prototyped and manufactured in a wide array of materials.

Fabricating customised products with sophisticated design and advanced attributes while ensuring the highest quality standards, is only possible in the non-traditional methods of manufacturing, such as AM. This decentralised approach of AM offers a myriad of manufacturing and customisations across virtually all industries such as aerospace, space, lifestyle, biomedical, manufacturing, etc.

The constant drive for innovation has helped industries recognise the vital role that digital technologies play in the AM ecosystem. Part of the overall manufacturing process is controlled by software, automation, and machine learning, making it a highly digitised process. Digital technology helps to manage data more efficiently and significantly improves data-based decision-making. It also helps in reducing the time-consuming manual tasks by automating the AM processes.

Digital technologies in additive manufacturing

Digital Twin is an example of the effective use of smart manufacturing. A digital twin is an accurate virtual representation of a real-life physical component or part modeled using simulation and machine-learning from real-time data on the various physical aspects of the object. Digital twins contain a complete representation of all the stages of a product life cycle, from designing, simulation, manufacturing/printing, post-processing, testing, and quality-control to information on operation and maintenance of the component.

Digital Twin enables smart manufacturing and sets the stage for further innovation in AM while ensuring a significantly higher yield. Successful implementation of a Digital Twin in AM allows the manufacturing process to be customer-centric while helping manufacturers respond to the latest industry trends.

Despite the host of benefits that AM offers, there are also a few challenges that occur while delivering metal 3D printed high-quality parts at an industrial scale. Rigorous simulations and multiple iterations of the Design of Experiments (DoE) that can take a minimum of 2-3 months are required to mitigate the print process risks. Apart from this, higher equipment cost, post-processing time and efforts, limited availability of print parameters form a significant roadblock in the widespread adaption of Additive Manufacturing.

Integrating digital technologies creates a holistic approach to Additive Manufacturing.

It streamlines the manufacturing process from the design stage (including Design for Additive Manufacturing-DfAM) through production to servicing the metal 3D printed parts. Digital technology helps overcome many AM challenges through digitised process flow, digital inventory, digital supply chain, and software driving hardware.

Digitised process flow in AM

Digital technology optimises operation and improves the process flow through automation. Digitisation allows the use of technology to manage data digitally and enhance value, optimise costs, create new revenue, and improve customer experience.

Apart from these software solutions that vastly improve the metal 3D printing process flow, digital technologies also play an important role in facilitating Just-in-Time (JIT) production. Intech has also successfully adopted the Digital Inventory approach for the on-demand production of spares and parts. Digital Inventory requires only the library of the digital CAD models of the parts to be stored in a digital repository instead of maintaining physical storage.

As conventional inventory storage for low volume production incurs a high recurring cost, implementing the Digital Inventory approach will eliminate the need for physical inventories and significantly reduce supply chain, inventory/pipeline, transportation costs, lead time, reduce material wastage, and minimise the carbon footprint of the manufacturing operations. In conclusion, adopting the latest technologies like Additive Manufacturing can help industries leverage the various possibilities of integrating the digital manufacturing approach.

About the author

Sridhar Balaram is Founder & Director of Intech Additive Solutions Pvt Ltd - who develops and supplies metal 3D printers based on Laser Powder Bed Fusion (LPBF) technology. Intech is a complete solutions provider in metal AM systems and AM software. Sridhar Balaram has over three decades of rich experience in casting, metallurgy, and component machining.

Related Stories

Knauf India doubles capacity with new metal line at Khushkhera plant

The increased production capacity is expected to improve the company’s ability to meet rising domestic demand and support a wider portfolio of drywall and ceiling solutions.

Read more

US Semiconductor Policy Shift Threatens Motion Control Market Momentum

Manufacturers now weigh financial incentives against political involvement, softening the long-term outlook for US semiconductor expansion.

Read more

Marelli Unveils Intelligent Energy Management System for Hybrid and Electric Vehicles

This holistic approach to vehicle energy optimisation maximises efficiency across all vehicle systems, delivering enhanced battery range, optimised fast charging and improved longevity.

Read moreRelated Products

Auto Casting Components

Micro Melt offers a wide range of auto

parts casting components.

Robofinish Iron Casting Fettlingrcf

Grind Master Machines Pvt Ltd offers a wide range of robofinish iron casting fettling CF-HD series.

Casting Components

Micro Melt offers a wide range of auto parts casting components. Read more