Schedule a Call Back

Lubricants for safe production - Kl?ber Lubrication supports food safety

Industry News

Industry News- Sep 16,15

Bangalore, 16th September 2015 - Food and beverage producers focus on consumer safety. An important part of assuring this is to produce in a safe and hygienic environment using safe lubricants. But how can the manufacturer be sure that the lubricants he uses are safe?

Kl?ber Lubrication production plants are certified according to the ISO 21469 standard for the production of premium quality H1-registered lubricants. Additionally, Kl?ber Lubrication promotes food safety as a member of the European Hygienic Equipment Design Group - the EHEDG.

As a consortium of experts from the machine and component building industries, the EHEDG supports hygienic design in all areas of food production. Lubricants are considered machine components, which motivated an expert group of the EHEDG to create a Guideline -Document 23- specifically for lubricants. Similar to ISO 21469, this EHEDG Guideline describes binding hygiene measures to be used for the manufacture of H1 lubricants. It also contains instructions for the changeover of production machinery or its components to H1 lubricants.

The EHEDG lubricants subgroup exclusively recommends the use of H1 lubricants in food production. To quote the EHEDG, "There are many cases where operators knowingly or unknowingly use H2 lubricants for production sites in which H1 lubricants are required - either for economic reasons or by simply misunderstanding the use of H1 in comparison to H2". Despite the classes' similarity, and whilst it may seem acceptable to use H2 lubricants, the EHEDG opposes this as in some cases they may even turn out to be toxic.

Kl?ber Lubrication advocates that all food and beverage producers use only H1 lubricants and complement them by a service package like Kl?berEfficiencySupport consisting of comprehensive training on lubricants and lubrication management including the creation of lubrication charts, optimising lubricants and many more activities supporting safe lubrication.

Kl?ber Lubrication is one of the world's leading manufacturers of speciality lubricants, offering high-end tribological solutions to virtually all industries and markets worldwide. Most products are developed and made to specific customer requirements. During its more than 80 years of existence, Kl?ber Lubrication has provided high-quality lubricants, thorough consultation and extensive services, which has earned it an excellent reputation in the market. The company holds all common industrial certifications and operates a test bay hardly rivalled in the lubricants industry.

Kl?ber Lubrication, set up as a retail company for mineral oil products in Munich in 1929, is today part of Freudenberg Chemical Specialities SE & Co. KG, a Business Unit of the Freudenberg Group, Weinheim. Kl?ber Lubrication has approximately 2000 employees in more than 30 countries.

Related Products

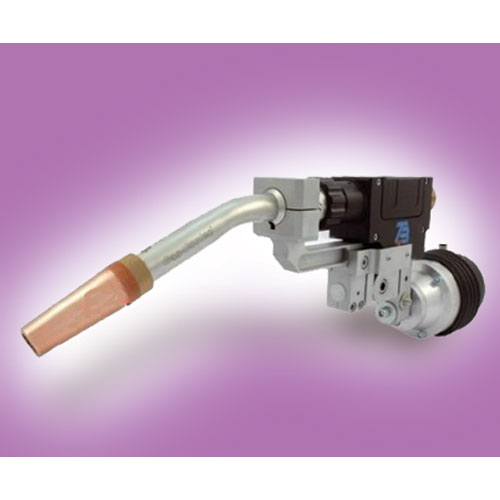

Welding Automation

Drupe Engineering Private Limited is offering a wide range of welding automation.

Robo Mig Tbi Robot Welding Torches

Mehta Sanghvi

& Company manufactures Robo MIG TBI robot welding torches.

Heavy Duty Goliath Crane

Ganesh Engineering Co manufactures and supplies a broad array of heavy-duty goliath crane.