Schedule a Call Back

Key Technology launches new Spinach Sorting System

Industry News

Industry News- Nov 20,14

November 19, 2014 - Key Technology of USA has introduced a new sorting system for fresh spinach. The integrated system includes an Iso-Flo fines removal shaker or dewatering shaker together with an acceleration belt and Manta digital sorter to inspect fresh spinach and other leafy greens such as cut cabbage, romaine, and iceberg lettuce. It is ideal for sorting fresh product at receiving, after cutting, or after washing and drying. This integrated system improves the accuracy of foreign material (FM) and defect removal to enhance product quality and food safety while increasing throughput and maximizing yield.

"Fresh spinach can be very hard to sort because the leaves are light and flat, so they fly like a sail. It tends to lift and roll, which makes it difficult to stabilize for accurate inspection and the targeting of rejects. Overcoming this challenge required a series of very specialized product handling solutions," said Marco Azzaretti, Advanced Inspection Systems Product Manager at Key Technology. "With our product handling expertise and our sorting expertise combined, we designed this very successful integrated system for sorting fresh spinach."

In tests, this new sorting system removed 100 per cent of the foreign material while achieving a false reject rate of only 0.5 per cent.

Successfully stabilising the spinach enabled Key to increase the belt speed of Manta by 30 per cent, which increases capacity. Featuring a Manta 2000 series sorter, this new fresh spinach sorting system inspects up to 13,000 lbs (5.9 metric tonnes) of spinach per hour. When sorting cut romaine or iceberg lettuce, the system inspects up to 12,000 lbs. (5.5 metric tonnes) per hour. On cut cabbage, it can process up to 50,000 lbs (22.7 metric tonnes) per hour.

When located at receiving or after cutting, the first step in the process is a three-deck Iso-Flo fines removal shaker that removes small objects such as dirt clods, insects, sticks, small rocks, and cotyledons to reduce the load on the digital sorter. If the system is located after washing and drying, an Iso-Flo dewatering shaker is the first of the three integrated steps.

Next, a specialized acceleration belt spreads, singulates, and stabilizes product for optimal presentation to the sorter. By providing an ideal view of each object to the sorter's vision system and improving the consistency of each object's trajectory from inspection to ejection, the accuracy of FM and defect removal is improved, which maximises product quality and yield.

Related Products

Superbolt Tool

Nord-Lock India Pvt Ltd offers a wide range of Superbolt

tool.

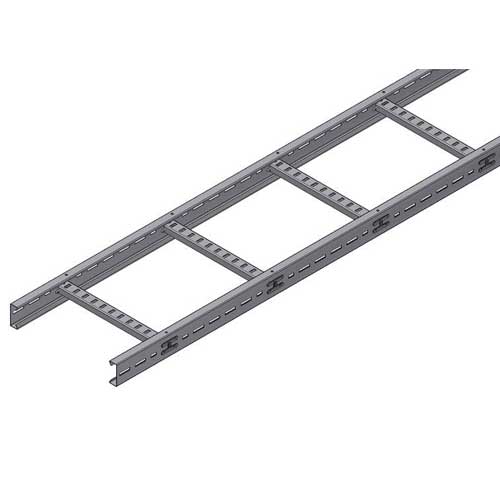

Ladder Type Cable Tray

Rama Enterprises offers a wide range of ladder type cable tray.

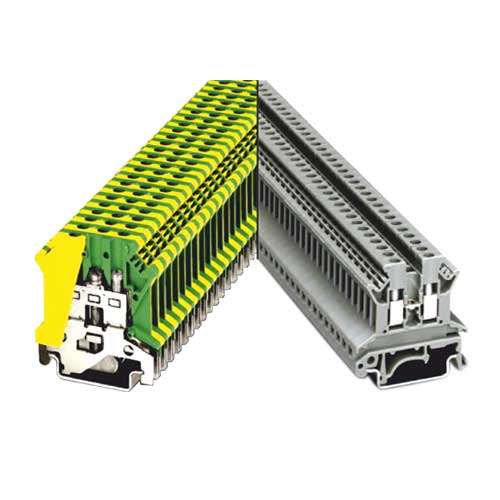

78 Series Din Rail Terminal Blocks

Werner Electric Private Limited offers a wide range of 78 series din rail terminal blocks.