Schedule a Call Back

Kennametal and Haimer Sign Agreement for KM4X Spindle Connection

Industry News

Industry News- Aug 27,13

In an agreement signed in July 2013, Kennametal has granted global toolholding leader Haimer GmbH (Germany) license to provide Kennametal?s new and advanced KM4X spindle connection solution throughout Haimer?s global markets. Haimer, a global leader in toolholding technology and provider of the innovative SAFE-LOCKTM pullout-prevention technology, together with Kennametal sees significant benefit for manufacturing customers.

"The KM4X spindle connection is the most rigid system in the world today. This design enables manufacturing companies to maximize their capital investments. KM4X enables higher metal removal rates, which facilitates higher machine tool utilization and reduced cost per part, while increasing the manufacturer?s available capacity," says John R Tucker, Vice President and President of the Industrial Business Segment for Kennametal Inc. "Having an innovative technology partner like Haimer supply the KM4X connection in addition to toolholders like Safe-LockTM will create a powerful production advantage for manufacturing companies around the world."

"This agreement is a perfect fit because it confirms both Haimer and Kennametal as leaders in high-end innovative technologies for world manufacturing," says Andreas Haimer, director and member of the executive board of Haimer GmbH. "We are honored and plan to actively support and educate our markets to the benefits of these mutually beneficial technologies."

The spindle connection, the interface between the machine tool?s spindle and toolholder, has to provide the torque and bending load capacity compatible with machine-tool specifications. Cutting forces, particularly in roughing or machining high-strength materials, generate bending moments that will exceed the interface?s limits prior to reaching torque limits. By combining high clamping force and optimized interference levels, KM4X provides a robust connection, extremely high stiffness, and bending load capacity for greatly improved performance in machining high-strength alloys and other materials. This means extremely high metal removal rates and more completed parts per day.

(Kennametal India Limited, Bangalore. Tel: 080-22198444. Email: bangalore.information@kennametal.com)

Related Products

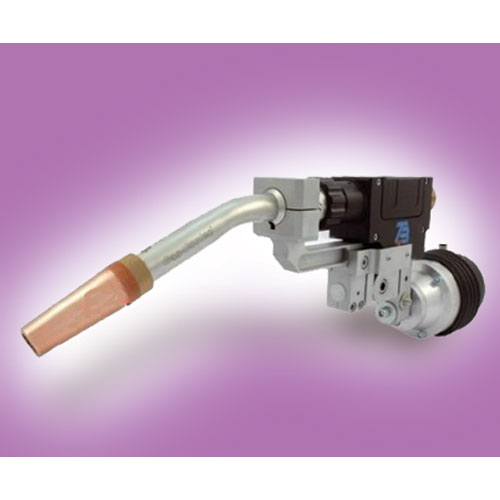

Welding Automation

Drupe Engineering Private Limited is offering a wide range of welding automation.

Robo Mig Tbi Robot Welding Torches

Mehta Sanghvi

& Company manufactures Robo MIG TBI robot welding torches.

Heavy Duty Goliath Crane

Ganesh Engineering Co manufactures and supplies a broad array of heavy-duty goliath crane.