Schedule a Call Back

Innovation meets technology at the 12th edition of Die & Mould India

Industry News

Industry News- Apr 29,22

The 12th Biennial Die & Mould India international exhibition, organised by Tool & Gauge Manufacturers Association of India (TAGMA), provided an ideal opportunity to bring the latest technologies and products for the fast-evolving die & mould industry under one roof. The four-day event not only showcased various technological developments for the booming die and mould industry, but also highlighted opportunities and challenges as well as provided a platform for toolmakers to learn from the user industry.

Speaking at the inauguration, D M Sheregar, President, TAGMA India, said, “The last two years have been challenging for all of us personally as well as professionally. However, the industry has emerged stronger and is ready to tap the growing demand for tools in the country. As COVID-19-related challenges fade away and the Indian manufacturing industry is witnessing growth opportunities, the 12th Die & Mould India exhibition aspires to play the role of a facilitator.”

Highlighting the opportunities and challenges in the industry, Vidyadhar Limaye, Senior Director at IAC Group, said, “I am familiar with the tooling industry and have witnessed its growth journey. India’s toolmakers have made significant contributions to the global manufacturing sector. However, our automobile industry is still heavily reliant on foreign toolmakers because of our toolmakers’ limited capacity. If we find a way to bring toolmakers together to maximise capacity utilisation, the Indian tooling industry will be able to meet the fast-paced demands of various sectors and will be able to tap the growing opportunities.”

In his keynote address, Prabhakar Kadapa, Partner & Director at Mudita Strat-Aegis Consultants Pvt Ltd, said, “The tooling industry has come a long way in the last 40 years. The sector has seen a lot of advancements and is now catering to demands from some global customers. The tooling industry’s evolution over the next 5 to 10 years will be mindboggling. While Indian tooling companies lack the specialisation that the global market demands, the scenario is slowly changing. Indian toolmakers are adopting the latest technologies, like their global counterparts. I feel that the Indian tooling industry has major export potential.”

D Shanmugasundaram, Vice President, TAGMA India, said, “We are all aware that we come from the industry that forms the backbone of the manufacturing sector. The tooling industry is often referred to as the mother industry because without toolmakers no product development can take place in any industry be it automotive, aerospace & defence, packaging, electronics, toy making, or railways, among others. Toolmakers, if you carefully observe, every industry is brimming with a plethora of opportunities. Undoubtedly, the pandemic is still posing challenges. But the overall future looks promising. After the success of ‘Make in India’, we are optimistic that the ‘Aatmanirbhar Bharat’ campaign will help us grow further.”

Related Stories

L&T Onshore Secures Major EPCC Order from Petronet LNG at Dahej

L&T Onshore wins a large turnkey order from Petronet LNG for LNG, ethane and propane storage facilities at Dahej.

Read more

Greenfuel Launches Ferrule-less Tube Line to Boost Make in India

Greenfuel Energy Solutions opens a new ferrule-less tube line in Manesar, enhancing local manufacturing, technology transfer, and alternate-fuel vehicle support.

Read more

Texmaco Wins Rs 150.6 Mn Contract for Ballastless Track Systems in Delhi Metro

The ballastless track system is a key component of modern metro infrastructure globally, offering enhanced stability, reduced maintenance, and superior performance under high-frequency operations.

Read moreRelated Products

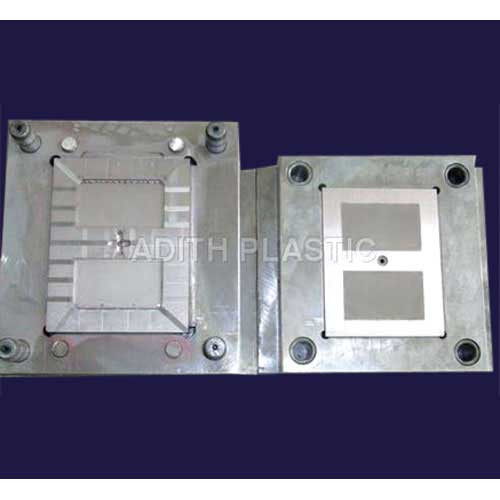

Industrial Moulds

Adith Plastic offers moulds for industrial electronic parts.

Industrial Plastic Moulding Dies

Adith Plastic offers a wide range of industrial plastic moulding dies.

Component Moulds

Innovative Moulds & Dies offers a wide range of plastic component moulds. Read more