Schedule a Call Back

Industrialisation and urbanisation drive the HVAC market in India

Articles

Articles- Aug 29,24

Related Stories

New Liquid Cooling Module from MAHLE Enters in Battery Storage

The company is leveraging its experience in developing and producing cooling modules for electrified buses.

Read more

Tata AutoComp to Showcase Railway Solutions at IREE 2025

The company’s joint ventures will enable end-to-end manufacturing and assembly of key railway components within the country, contributing to the Make in India and Atmanirbhar Bharat initiatives.

Read more

50 Years of EMO: People, Machines, Milestones

The success story of the world's leading trade fair – from "Bonjour électronique" to "Hello AI", says Nikolaus Fecht, a technology journalist, as he writes about the evolution of EMO.

Read moreRelated Products

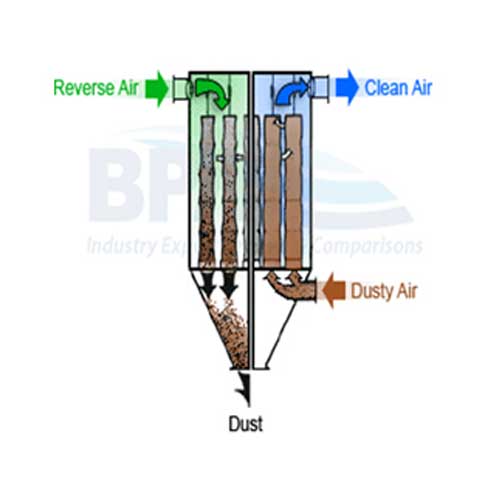

Reverse Air Bag House

ABR Enviro Systems offers a wide range of reverse air bag house.

High Quality Air Knife System

Superchillers offers high quality air knife system. Read more

Compact Cylinders -Vadvu Series

Vijay Air Control offers a wide range of compact cylinders -Vadvu Series