Schedule a Call Back

Igus works with manufacturers to expand low cost automation

Technical Articles

Technical Articles- Feb 17,23

As a result of continuous developments and product innovations, affordable robotics has become especially interesting for small and medium-sized companies and the number of offers on the market is increasing. For instance, igus low cost automation represents a broad portfolio of articulated arm, linear, delta and SCARA robots. Product modularity means that single components or individual complete solutions can be assembled according to the build-or-buy principle. The focus is always on a low entry-level price and quick payback. This is where igus high-performance plastics play to their strengths. They are tribologically optimised and durable, lightweight, lubrication-free and maintenance-free, and cost-effective to produce.

The most cost-effective solution that works

Over the past three years, igus has built up a broad, constantly growing partner network. As

part of the LCA partner programme, the motion plastics specialist works with integrators

who provide customers with additional expertise, experience with end customer projects,

and joint project experience. "We started with seven partners around two years ago, and

we now have almost 100. In order to refer interested parties to competent integration

partners in their area, we are constantly expanding our network. Together, we can offer our

customers a wide range of automation solutions - focussing on applications with a total

investment volume of less than €45,000. We work with our customers to select the ideal

integrator for the application in order to find the best and most cost-effective solution," told

Alexander Mühlens, Head of Automation and Robotics, igus. Typical services include

integrating a control system into existing machines, setting up and commissioning robots,

evaluating safety measures or, if there is simply no capacity, providing the capability of

assembling machines on site.

Experience low cost automation live on site

Like igus, many integrators have set up a customer testing area so that customers can

experience igus low cost automation live. "Nothing is more convincing than being able to

experience robot programming or gripper adaptations yourself on site in just 30 minutes.

That's why we have over 30 customer visits a week in Cologne alone", said Mühlens. The range of test areas is wide: from a delta robot cell at ITQ GmbH in Garching near Munich to a 150-square-metre area with four robots and linear robot axes at Provitec near Heilbronn to a 1,400-square-metre customer testing area at Truphysics in Stuttgart with 300 square metres of space just for igus products. With its own low cost automation roadshow, igus works with the integrator partners to organise events or visit customers directly on site.

"We have already organised roadshow events in Germany, Denmark, Sweden, Finland, Poland, Belgium, France, Switzerland, and the Netherlands, attracting a total of around 3,500 visitors. The aim of the roadshow is to always automate directly on site," added Mühlens.

RBTX online marketplace: new partners are adding more and more new products to the

range

Since 2019, users have also had access to the igus RBTX marketplace - an online marketplace

that brings users and manufacturers of low-cost robotics together. Mühlens said, "At

RBTX.com, interested parties can currently find compatible components from a total of

78 partners. The marketplace currently has 100 low-cost applications with parts lists and

hardware and software compatibility for price transparency. As an open marketplace, we

are always interested in new partners for the low-cost robotics mission, so that we can

ultimately provide interested parties with even more individual solutions for their specific

application." Partners benefit from a new digital sales channel and can expand their

customer base and open up new markets - a win for everyone involved.

Related Stories

India is a key strategic market for Hexagon: Jason Walker

In this interaction with Rakesh Rao, Jason Walker, VP, General Manufacturing Practice Lead, Hexagon, sheds light on the factories of the future and importance of India for Hexagon.

Read more

AWSi showcases office-on-wheel at Hannover Messe 2025

Recently, August-Wilhelm Scheer Institute (AWSi) collaborated with an Indian company to develop AI-driven tools to optimise insect farming operations

Read more

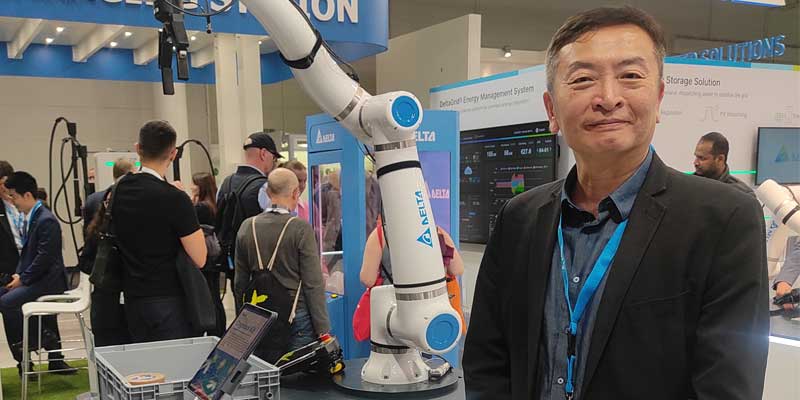

Localisation is Delta Electronics’ key strategy in India: Andy Sun

In this interview with Rakesh Rao, Andy Sun, Deputy Head Industrial Automation, Delta Electronics, discusses manufacturing trends and Delta’s future growth plans for the industrial automation divi..

Read moreRelated Products

Spur Helical Gear

J S Engineering Works offers an assortment of spur helical gear with primarily rolling tooth contact.

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Ground Spiral Bevel Gear

Bevel Gears (India) Pvt Ltd offers a wide range of ground spiral bevel gear.