Schedule a Call Back

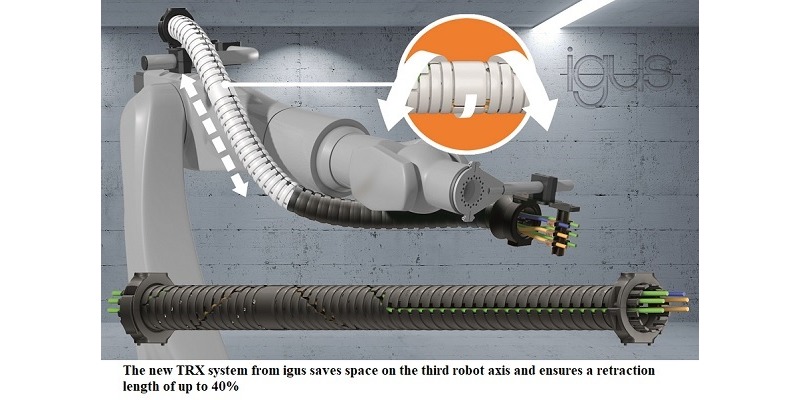

Igus’ new triflex TRX energy supply system revolutionises 3D motion of robots

Industry News

Industry News- Jul 28,21

Related Stories

Bharat Forge and Agile Robots sign MoU to Advance AI-Led Industrial Automation

The MoU brings together Bharat Forge’s manufacturing expertise and Germany-based Agile Robots’ AI-led robotics capabilities to accelerate intelligent automation across key civilian industrial se..

Read more

ReBeLMove Pro: Modular robot platform for logistics, assembly and handling

It is based on a compact, rectangular transport robot on four wheels with an electric drive.

Read more

Physical AI Emerges as the Operating System of the Modern Industrial Economy

Physical AI is transforming automation by merging robotics and generative AI to reshape productivity and unlock new industrial applications, shares Dijam Panigrahi, Co-founder and COO, GridRaster In..

Read moreRelated Products

Compact Fmc - Motorum 3048tg With Fs2512

Meiban Engineering Technologies Pvt Ltd offers a wide range of Compact FMC - Motorum 3048TG with FS2512.

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.