Schedule a Call Back

Honeywell launches AI software to optimise gigafactory operations

Industry News

Industry News- Jun 17,24

Related Stories

Bharat Forge and Agile Robots sign MoU to Advance AI-Led Industrial Automation

The MoU brings together Bharat Forge’s manufacturing expertise and Germany-based Agile Robots’ AI-led robotics capabilities to accelerate intelligent automation across key civilian industrial se..

Read more

Spray Engineering Devices drives Parag Agro’s 7000 TCD expansion

SED’s phased modernisation programme has enabled Parag Agro to scale sugar production to 7,000 TCD while achieving significant gains in energy efficiency and sustainability.

Read more

Aimtron enters railway signalling with focus on safety-critical electronics

Aimtron Electronics has expanded into railway signalling electronics, leveraging its regulated manufacturing expertise to support safety-critical rail and metro infrastructure in India.

Read moreRelated Products

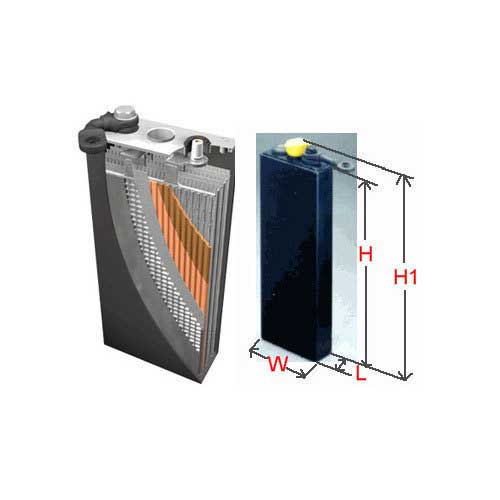

Forklift Battery

Aatous International is a manufacturer and solution provider of a wide range of forklift battery.

Kusam Meco -Wrist Type High Voltage Alarm

‘KUSAM-MECO’ has introduced a new wrist Type High Voltage Alarm Detector - Model KM-HVW-289 having a wide sensing range from 1kV-220 kV AC.

Servotech Power Systems files 2 patents for energy management technologies

Servotech Power Systems, a leading manufacturer of EV chargers and solar solutions, has announced that it has filed two patents for innovative energy management technologies in order to facilitate gri Read more