Schedule a Call Back

HEG to invest Rs 1000 cr to set up graphite anode plant

Industry News

Industry News- Nov 28,22

The Noida-headquartered HEG Ltd, an LNJ Bhilwara group company and a manufacturer of synthetic graphite, plans to invest Rs 1000 crore (approximately) over the next 3 years to set up a production facility of graphite anode for lithium–ion batteries. The upcoming plant will cater to 10-12 GWh of cell manufacturing capacity and the investment will be executed through its newly incorporated, wholly-owned subsidiary, The Advanced Carbons Company (TACC).

The investment, according to HEG, will be made in two phases. Phase 1 is expected to be operational by 2025 with an investment of about Rs 1000 crore. In phase 2, the company plans to double the capacity with another Rs 1000 crore. HEG aims to finish both the phases in the next 5-7 years, thanks to its decades of experience in the graphite and advanced carbon chemistry fields. HEG Limited is likely to create 400 new jobs with this project.

The importance of anode

Graphite anode is one of the most crucial elements in the production of cells, accounting for roughly 10-15 per cent of the cost. For every GWh of Li-ion cell production, 1,100 tonnes of graphite anode is needed. Synthetic graphite anode offers improved performance and uniformity and has gradually eclipsed natural graphite as an anode material for Li-ion batteries. Currently, Li-ion cells are either imported directly as assembled battery packs from China and Taiwan or they are imported before being manufactured into batteries in India. The lithium-ion battery, which makes up 40–50 per cent of the overall cost, is the most expensive part of an electric car. When graphite anodes are made available in India, the cost of cell production will decrease. It will also help in advancing India’s green energy goals and achieve net zero emissions by 2070.

HEG plans to play a significant part in making India carbon neutral. The Indian government's Production-linked Incentive (PLI) scheme mandates 60 per cent domestic value addition for cell production. Anode material produced in the country will be essential in meeting this requirement.

Riju Jhunjhunwala, Vice Chairman, HEG Ltd, said, “With Project TACC, our goal is to accelerate India's push towards green energy, with a primary focus on improved carbon materials that support green energy in addition to graphite anodes. Only China and Japan are the major producers of anode materials at the moment. More than 90 per cent of the market is controlled by businesses in these two nations. The LNJ Bhilwara Group will be making a modest contribution to India's Atmanirbhar Bharat project with its investment in anode.”

Ankur Khaitan, MD and CEO, The Advanced Carbons Company, added, “India has enormous potential for large-scale battery production; it is anticipated that by 2030, the country's annual market for stationary and mobile batteries will have surpassed $15 billion, with a demand increase of 260 GWh (as per Niti Aayog report). One such measure that supports this market is the government's recently announced PLI scheme. Additionally, it would work as a motivator to increase India's capacity for battery production. With this expansion, the business is well-positioned to meet the growing demand for the raw ingredients needed to make batteries.”

The company intends to build TACC as a cutting-edge facility on more than 100 acres of land, where it would set up an anode plant with a production capacity of 20,000 metric tonnes per year. The building will have a specialised innovation centre for creating new carbon derivative materials, such as graphene and carbon nanotubes, for use in green energy applications.

India would need batteries with a capacity of about 60 GWh by 2025, and 260 GWh by 2030, according to government estimates. India is one of the most promising markets for anodes, and the global opportunities continue to be a desirable route. Globally, the anticipated rise is considerably greater, and by 2030, it's estimated that more than 3300 GWh of yearly manufacturing of Li-b cells will be in vogue.

As world’s leading graphite electrode manufacturer, HEG Limited has the largest single-location graphite electrode plant with manufacturing capacity of 80,000 Mt going up to 100,000 Mt, at Mandideep in Madhya Pradesh. The company exports over 70 per cent of its production to more than 30 countries around the world.

Related Stories

Toyota Kirloskar Motor Showcases Flex-fuel Hybrid Tech

Toyota Kirloskar Motor highlights flex-fuel strong hybrid technology, skilling initiatives and industry collaboration at the Advantage Maharashtra Expo 2026 in Chhatrapati Sambhajinagar.

Read more

Ashok Leyland opens green mobility-focused greenfield plant in Uttar Pradesh

Designed primarily for electric vehicle manufacturing, the plant has an annual production capacity of up to 5,000 vehicles.

Read more

Copper Prices Hit Record Above $13,000 per Tonne

Supply fears and AI-led demand drive sharp rally

Read moreRelated Products

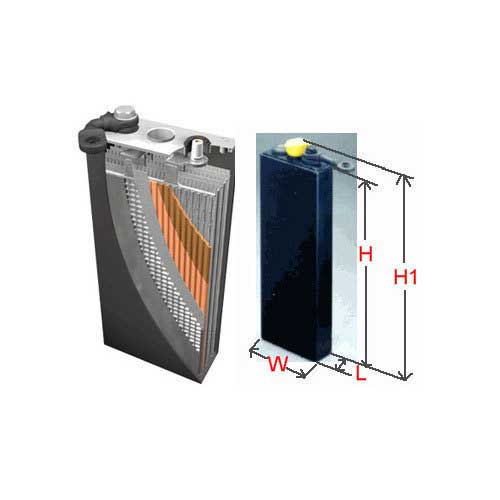

Forklift Battery

Aatous International is a manufacturer and solution provider of a wide range of forklift battery.

Kusam Meco -Wrist Type High Voltage Alarm

‘KUSAM-MECO’ has introduced a new wrist Type High Voltage Alarm Detector - Model KM-HVW-289 having a wide sensing range from 1kV-220 kV AC.

Servotech Power Systems files 2 patents for energy management technologies

Servotech Power Systems, a leading manufacturer of EV chargers and solar solutions, has announced that it has filed two patents for innovative energy management technologies in order to facilitate gri Read more