Schedule a Call Back

Gleason celebrates 125 years of gear technology

Industry News

Industry News- Apr 30,21

Gleason-Hurth Tooling GmbH, Munich, Germany, celebrated its 125th anniversary on April 3, 2021, a significant milestone in its rise from a small workshop on Munich’s Viktualienmarkt, to one of the world’s leading innovators in the production of high-precision workholding and tools for the global gear manufacturing industry. Products today include some of the most advanced and productive shaving cutters, chamfering and deburring tools, master gears and setting masters, honing and grinding tools, as well as diamond-plated dressing tools for a wide range of applications.

Most recently, the company’s plant facilities on Moosacher Strasse in Munich Milbertshofen have been completely renovated with state-of-the-art equipment and extremely efficient workflow and quality processes. In addition to the ultra-modern, digitized production, the newly designed office environment offers employees all the amenities and benefits of a creative and flexible working environment.

Company officials credit much of Gleason-Hurth

Tooling GmbH’s continued success to its workforce of skilled and dedicated

employees. The company continues to train its own apprentices to hand down

critical skills and methodologies to the next generation of coworkers. Indeed,

a large part of the company’s workforce today completed their apprenticeships

at the Gleason-Hurth Tooling GmbH plant. The facility also serves as a training

center for the global Gleason Academy with an extensive program of training,

seminars and webinars.

Today, Gleason-Hurth Tooling GmbH is poised for significant future growth, and well positioned to meet fast-growing demand for innovative new drive concepts for electric vehicles, and other emerging products using increasingly complex, high quality gears.

In 1896, mechanic and tinkerer Carl Hurth founded his first workshop in a backyard at Frauenstraße 19 on Munich's Viktualienmarkt. The development of his own gear hobbing machine in 1904 marks the beginning of his specialization in gear manufacturing. The business expands to such an extent that in 1911 the Carl Hurth Maschinen- und Zahnradfabrik was built at Holzstrasse 19 in the Glockenbach district of Munich.

In the 1920s, the son of the company founder, Hans Hurth, took up the manufacture of motorcycle gearboxes. The company now employs 800 people. In 1935, cylindrical gear shaving was added to the manufacturing program. In the following decades more than 100,000 shaving cutters are produced and shipped globally.

From 1958 on, machine tool building activities continued in Moosacher Strasse in Munich Milbertshofen. Six years later the plunge shaving process is developed, which – to this day – is one of the most widely used processes for gear finishing. Supported by the rapid economic growth of the time, employment in Munich increased to over 3,000 people in 1969. In 1983, the two Munich plants in Moosacher Strasse were merged to bundle activities related to gear technology. Hurth achieves world fame with transmissions for tractors, marine applications and rail traffic, including those for Munich's subway and commuter trains. With the introduction of "Power Honing" in 1993, Hurth again heralded a trend-setting development in hard finishing of cylindrical gears.

In 1995, the Machines and Tools division was acquired by Gleason Corporation. Gleason leverages the long-standing relationships of both companies to drive the group's expansion in the global marketplace. The company now operates as Gleason-Hurth Machinery and Tools. Within the Gleason group, the Munich site becomes the competence center for fine finishing of cylindrical gears. The product range of gear manufacturing machines includes chamfering, shaving, honing and threaded wheel grinding machines as well as corresponding automation, workholding and tools. With the reorganization of Gleason’s European Competence Centers in 2015, machine building was relocated to the Gleason-Pfauter facility in Ludwigsburg. The Munich site now concentrates on workholding systems and gear manufacturing tools and operates as Gleason-Hurth Tooling GmbH.

While the company will celebrate its 125th anniversary on April 3, 2021, the planned open house and company celebration will be postponed to 2022 due to the pandemic.

Related Stories

The 3D metal revolution

India is rapidly emerging as a frontrunner in the world of 3D metal printing, a technology that is reshaping the way industries approach manufacturing. From aerospace to automotive, healthcare to de..

Read more

BYD India to showcase globally acclaimed models at Bharat Mobility Expo 2025

Plans to display new models including internationally successful models and BYD’s India line-up. BYD’s participation in Bharat Mobility and the upcoming launches of the new models is a testament..

Read more

Renewable energy sector to generate 43 mn jobs in India by 2050: CMD, IREDA

While delivering the Visionary Talk hosted by the 39th Indian Engineering Congress at Kolkata on December 20, 2024, Pradip Kumar Das spoke about the critical need for talent to drive the renewable e..

Read moreRelated Products

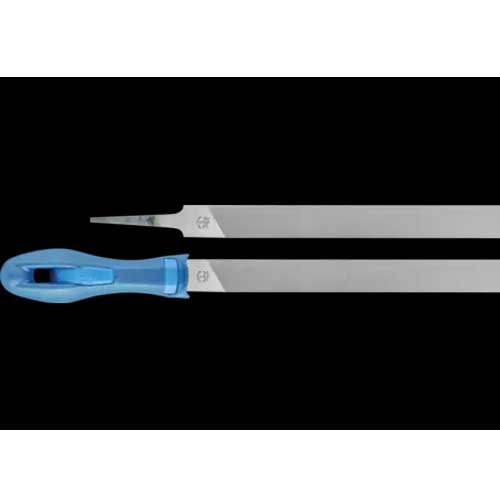

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.

Ss Hex Head Bolts

Trychem Metal And Alloys is offering SS hex head bolt.

Cutting Tools

Get Cutting Tools provides a wide range of CNC cutting tools