Schedule a Call Back

Flender reinvents itself at Hannover Messe 2023

Articles

Articles- May 27,23

Flender has been building gear units for industrial applications for over a century. In the 1990s, the drive specialist redefined industrial gear units and set the global grey standard with the Flender gear unit. It is impossible to imagine the market without the countless modular gearboxes bearing the Flender logo. "We are now reinventing this standard," said Andreas Evertz, CEO of the Flender Group, at the presentation of the successor Flender One at the Hannover Messe 2023, held in Hannover (Germany) from April 17-21.

Individual: On-point configuration for all requirements

Flender One's approach is even more revolutionary than its predecessor. "Flender One is not a series product, although it is manufactured in exactly the same way," he said. The secret behind it: maximum individuality and variability in the configuration and manufacture of the gear units. In most cases, different performance requirements, environmental conditions and installation positions make an individual gearbox solution necessary.

Flender engineers have succeeded in developing the world's narrowest gear ratio range with 103 stages between 1 and 7.1 per size for applications that require particularly precise speed, such as pumps and paper machines. This allows the rotational speed to be set almost ideally for maximum efficiency in these applications. The deviation between the desired speed and the available technical solution is at the utmost of 1.5 percent. This gives customers the optimum speed for their plant. Like its predecessor, Flender One will be available in all required sizes and attachments for the industry. This means it can be used in all applications and can replace an existing predecessor gearbox one-to-one and in plug & play without any modifications.

On the way to the customised gearbox

The Flender One platform even goes one step further, which the gearbox specialist also presented at the Hannover Messe 2023. In the future, further expansion stages will make it possible to configure gearboxes tailored to the respective application and the associated requirements. Despite maximum individuality, customers will benefit from the advantages of series production: Process efficiency in production and thus fast delivery times and low costs.

This is made possible by a real milestone in drive manufacturing: the complete digitization of the engineering process. It triggers the design precisely according to customer requirements and translates it into a fully automated manufacturing and delivery process.

Buying gearboxes made easy

A novelty in drive technology will also be the new product configurator. Customers will soon be able to configure their customized gear unit online with just three parameters: Application, power and speed. More detailed requirements can also be added. Within seconds, the 3D data and a 360-degree preview of the gear unit are available. Flender developed the configurator along the customers’ requirements.

"We offer to take the time-consuming preliminary considerations off our customers' hands. We no longer ask for the specifications and features of the gear unit, but only for the desired benefits. Customers tell us how and where they want to use the gear unit, and we guide them to the gear unit for their purpose," said Dr Jan Reimann, Project Manager, Flender One.

Efficient: Saving raw materials, time and money with Flender One

Andreas Evertz, CEO, Flender, came up with a surprising fact when presenting Flender One. Most industrial gearboxes from all manufacturers in the field, including Flender, are oversized by up to 50 percent, he said. "You don't think so? We can prove it, because we've been measuring it for years. Customers and gearbox manufacturers did not want to take a risk and bought large designs. With Flender One, we no longer need this oversizing," said Evertz.

With the help of the collected data, Flender is now able to size the gearboxes only as large as is needed for the respective application. Rouven Daniel, President Industrial Gears, stated, “Efficiency is above all. Each gearbox is designed to meet individual requirements. The customer gets exactly what he needs - no less and especially no more.” The result is massive savings in raw materials, energy consumption, delivery times and installation space. Any waste is eliminated, which benefits the environment and the costs.

The new platform not only optimises efficiency during planning, but also during operation. The optimised Metaperform gearing reduces power loss by up to 50 percent compared with previous gear unit solutions. This is made possible by improved roll-off behavior and the even more uniform path of contac of the gearing. Together with the new overall gear unit design, this also increases the thermal capacity of Flender One. Features such as the concise cooling rib make additional, external cooling of the gearbox only necessary at a later stage or, depending on the application, completely unnecessary. This saves valuable energy and thus costs during operation.

Smart: The drivetrain becomes intelligent

The digital enabler of all measurements and optimisations is Flender's new gearbox intelligence AIQ. Its sensor technology and analysis functions continuously measure the torque and detect whether the gearbox and the plant are driven in overload or underload: the key to optimisation and automation of the production processes and, moreover, to perfect design and dimensioning of the gearboxes for future plants. Thanks to AIQ, the gearbox becomes the central player in a constantly optimising process that reduces CAPEX and OPEX and makes industrial production sustainable - thanks to raw material savings and more energy-efficient manufacturing processes.

The special feature of AIQ is the intelligence in the sensor. It not only records operating states, but also processes them directly, interprets them, and provides operators with recommendations for action - on site at the sensor, via app, or permanently in the customer's own system. This offers operators many opportunities to increase the profitability of their plants. The detailed condition monitoring of the individual components detects deviations from the optimum at an early stage and enables the prediction of possible failures. Operators are thus able not only to control the drive and processes, but to optimise them. Precisely scheduled maintenance and reduced downtimes are the result.

"Our goal is to make the world more sustainable together with our customers and partners. This is what our products stand for. With Flender One, our customers receive a completely new type of gear unit solution, precisely tailored to their application, exact to their requirements and preventing waste while utilising the smallest drive concept possible. If industrial gearboxes were cell phones, this drive would be the latest smartphone," said Andreas Evertz.

With the single-stage Flender One for paper and pump applications, Flender already introduced the first expansion stage to the market last fall. With the first multi-stage gearbox variants for overhead cranes, conveyor belts and bucket elevators, the next expansion stage will follow in the first half of 2024.

Flender headquartered in Bocholt, Germany, is a leading global supplier for mechanical and electrical drive systems and has the reputation for highest performance, innovation, quality, and reliability of drive components for more than 120 years. Flender offers a broad variety of gear units, couplings and generators and associated services, with a focus on key industries such as wind power, cement, mining, oil & gas, power generation, water and wastewater, marine, conveyor and crane technology. Flender products and services combine the latest technology with extremely high quality and have been reliably providing the optimal transmission of power for decades.

Related Stories

How MNCs are strategising to capture market in India

Today, the Indian MNC scene is changing vastly, with many new ones setting up shop in India. With China becoming less attractive, India is becoming the go to place, writes R Jayaraman and Firoz S Ri..

Read more

Smart Factories in India: Reality or Distant Dream?

As India moves toward its goal of becoming a $7 trillion economy by 2030, embracing smart manufacturing technologies will be crucial for achieving this ambitious target, writes Rakesh Rao. But, is t..

Read more

Driving Efficiency: Schmalz Gripping Systems for India's Manufacturing Future

As the market demands speed, agility, and reliability, Schmalz gripping systems are enabling the next generation automation of Indian manufacturing sector.

Read moreRelated Products

Spur Helical Gear

J S Engineering Works offers an assortment of spur helical gear with primarily rolling tooth contact.

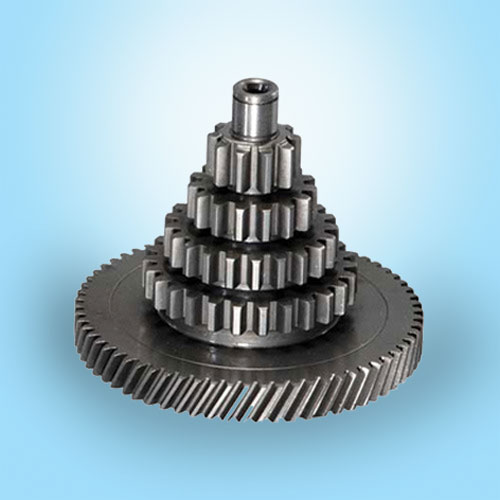

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Ground Spiral Bevel Gear

Bevel Gears (India) Pvt Ltd offers a wide range of ground spiral bevel gear.