Schedule a Call Back

Dürr launches new rear centre tank of the Airbus A321XLR

Industry News

Industry News- Aug 05,24

Related Stories

SKF Unveils ARCTIC15 Steel for Next-Gen Aeroengine Bearings

SKF has launched ARCTIC15, a high-temperature, corrosion-tolerant steel enabling next-generation, fuel-efficient aeroengine bearing designs

Read more

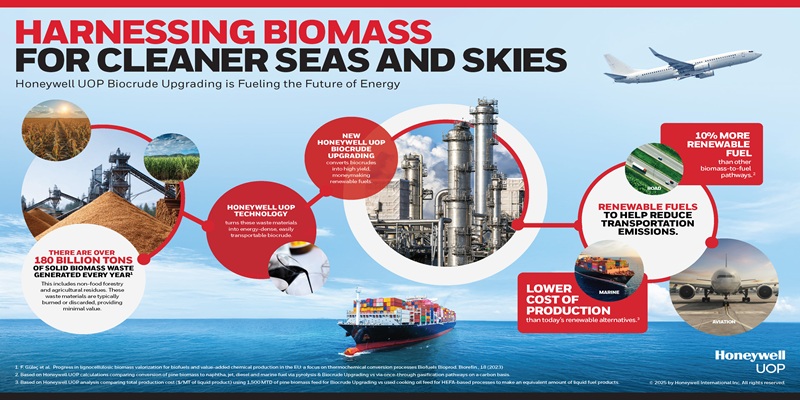

Honeywell Launch Biocrude Upgrading Tech for Sustainable Maritime Fuel

Honeywell’s new process technology enables biocrude to then be refined at major facilities to produce marine fuel, gasoline or SAF.

Read more

Air India and Airbus Launch Pilot Training Hub in Gurugram

The launch comes as Air India, under the Tata Group’s ownership since 2022, embarks on a significant fleet expansion following its order of 570 new aircraft.

Read moreRelated Products

Troop Comforts revolutionises military gear with indigenous innovations

Troop Comforts Ltd (TCL), a state-owned defence corporation, has recently received a request for proposal (RFP) from the Northern Command of the Indian Army for its indigenously developed military gea Read more