Schedule a Call Back

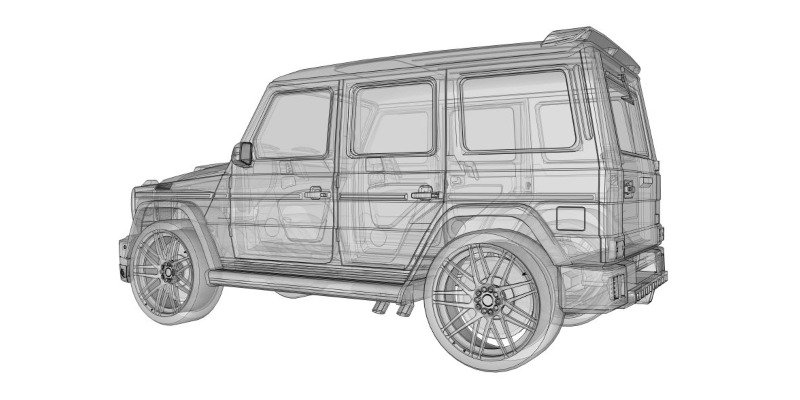

DEP’s vehicle parameterization tech reduces weight and makes it fuel efficient

Industry News

Industry News- Mar 30,21

Chennai

Increasing emphasis and high expectation on the fuel economy standards have pushed the automotive OEMs globally to optimise their vehicle platforms irrespective of the vehicle footprints. Fuel economy standards have to be achieved with holistically balancing of safety, noise vibration harshness (NVH) and durability performance regulation and requirements. With competitive markets and compressed time to market needs, OEMs are looking for technologies that enable them to cut short their development time or make their current platforms more efficient.

The entire value engineering is divided into three phases by Detroit Engineered Products (DEP) and is Baseline evaluation, Parametrization and Optimisation. The DEP technology, proprietary CAE software, MeshWorks and industry leading process have led to a multi-disciplinary optimisation approach that has been very well received by OEMs globally.

The technology of parameterizing complete vehicle CAE models using design enabled optimisation in DEP MeshWorks and the process of multi-disciplinary optimisation are the key pieces that deliver value. This CAE driven process has been deployed successfully in both early-stage vehicle development as well as for optimising existing platforms.

Conventional full vehicle CAE model build is generally driven by CAD data. This process though well-established takes a lot of time. Vehicle manufacturers are constantly looking at technologies that reduce the CAE model to manufacturing time. In yet other perspective, vehicle manufacturers are also looking at technology and tools that can help them quickly build and evaluate concepts.

Detroit Engineered Products (DEP) has been working on a transformational approach to both the conventional CAE model build as well as for early-stage concept model development. For instance, DEP's CAE model-based morphing, merging; cut & swap techniques have helped the customers accelerate not only their CAE model build an early-stage concept development timing but also have helped reduce the product development cycle time.

Radha Krishnan, Founder & President, Detroit Engineered Products (DEP) said, “DEP's MeshWorks Morpher driven MDO approach has been successfully extended beyond the full vehicle to various other vehicle subsystems as well. This feature-based morphing approach preserves and carries forward the integration and manufacturing best practices with the flexibility to change the shape and sections. Morphing technology and methods from MeshWorks have realized about 60 per cent time-saving in the pre-production design stage of vehicle development.â€Â

Related Stories

C-DEP–IIT Delhi Study Flags Tech Logistics Gains for MSMEs, Warns of GST Risks

C-DEP–IIT Delhi study shows tech-enabled intra-city logistics cut MSME costs, boost efficiency, but warns GST 2.0 may raise taxes.

Read more

IMTEX Forming celebrates human ingenuity & machine intelligence: Jibak Dasgupta

In this interview with Rakesh Rao, Jibak Dasgupta, Director General & CEO, Indian Machine Tool Manufacturers' Association (IMTMA), explores trends in the machine tools industry and shares some highl..

Read more

Saatvik Solar Industries Secures Rs 1775 Mn Orders for High-Efficiency PV modules

These orders have been awarded by reputed Independent Power Producers (IPPs) and EPC developers across India, reinforcing Saatvik’s position as a trusted and preferred module supplier in the count..

Read moreRelated Products

Measurement Software

Blum-Novotest Measuring & Testing Technology Pvt Ltd offers a wide range of measurement software.

OEM Cad Platforms

Graebert India Software Pvt Ltd offers OEM Cad Platforms. Build your own CAD solutions combining your specific features with the ready-to-use DWG-editing features of the ARES CAD Software. The fina Read more

Embedded System Design And Development

System Controls Technology Solutions Pvt Ltd offers Embedded System Design And Development. With the expertise to handle the product lifecycle from concept to completion,embeded we offer customised Read more