Schedule a Call Back

Constructing safely: Preventing slips, trips and falls

Articles

Articles- Jan 29,24

Related Stories

Manufacturing to Drive 46% of Industrial Leasing by 2027: JLL

JLL forecasts manufacturing leasing to reach 34 mn sq ft across top cities.

Read more

Best practices to ensure safer work at heights across industries

As industries expand infrastructure, ensuring safe work at height is vital. Kamarajan M, Head of Education, British Safety Council, India, outlines essential measures to reduce fall risks and safegu..

Read more

Greta Minerals Doubles WA Exploration Land, Targets Lithium Supply for India

The Gecko North Project, 25 km northwest of Coolgardie, is one of seven critical mineral and gold projects under Greta Minerals (Australia) Pty, which now holds 37 granted and 5 pending mineral tene..

Read moreRelated Products

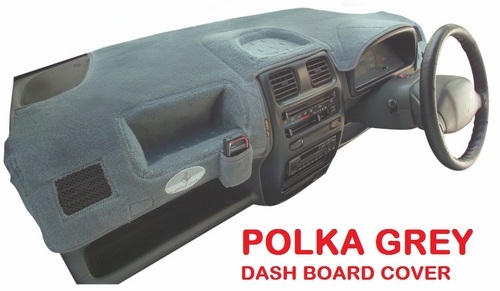

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.