Schedule a Call Back

CDIL eyes Semiconductor Fab in India amid expansion plans

Industry News

Industry News- Sep 20,23

Related Stories

Cummins India launches battery energy storage systems

The state-of-the-art energy storage solution reinforces commitment to India's renewable energy targets and bolsters grid stability initiatives.

Read more

Minda Corp, Toyodenso Form JV for Automotive Switches

The joint venture will set up a greenfield facility in Noida (Uttar Pradesh) with operations expected to commence in the second half of FY 2026–27

Read more

Let’s decarbonise: A turning point for mining in Asia

Sustainability uncertainties in mining are well known. Encouragingly, mining is already undergoing a notable transformation—one that brings with it great potential to build a more resilient and su..

Read moreRelated Products

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.

“Kusam-Keco” Partial Discharge Acoustic Imager - Model - Km-pdai

‘Kusam-Meco’ has introduced a new “Partial Discharge Acoustic Imager Model KM-PDAI.

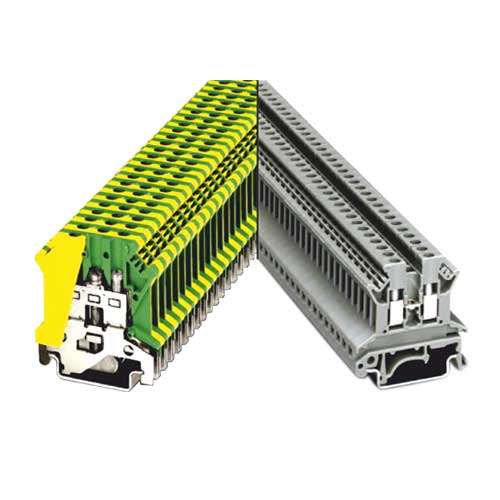

78 Series Din Rail Terminal Blocks

Werner Electric Private Limited offers a wide range of 78 series din rail terminal blocks.