Schedule a Call Back

BorgWarner receives BEV electric orders from global OEMs

Industry News

Industry News- Aug 07,24

Related Stories

Vipul Organics Automotive Organic Intermediates Exports Cross Rs 40 Million

Cumulative exports of this high value speciality intermediate have now crossed Rs 40 million, marking a strong and steady scale-up in global demand.

Read more

Shailesh Chandra Elected OICA President, Hildegard Müller as Vice President

Shailesh Chandra becomes first Indian OICA President; Hildegard Müller named Vice President, highlighting global leadership in automotive sustainability.

Read more

Toyota, Honda Step Up Investments to Make India Auto Hub

Japanese carmakers boost India presence as they cut dependence on China

Read moreRelated Products

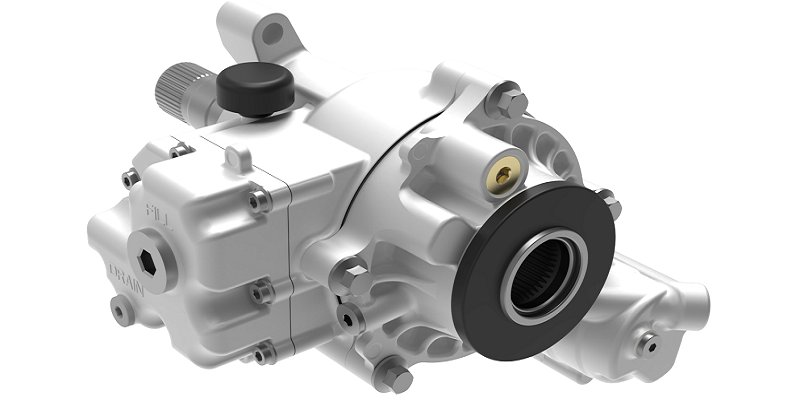

Automotive Oil Pump

Kalpak Auto Pvt Ltd offers a wide range of

automotive oil pump.

Tata Motors unveils facilities for development of Hydrogen propulsion tech

Tata Motors, India?s largest automobile company, unveiled two state-of-the-art & new-age R&D facilities for meeting its mission of offering sustainable mobility solutions. The unveilings constitute of Read more

Tata Motors plans petrol powertrain for Harrier and Safari SUVs

Tata Motors is in the process of developing a new petrol powertrain for its premium sports utility vehicles, the Harrier and Safari, as confirmed by a senior company official. Currently, these models Read more