Schedule a Call Back

Bohmen Industries is focussing on automation of core processes

Interviews

Interviews- Jan 22,24

Related Stories

Gandhi Automation’s sectional overhead doors provide unrivalled safety

Their robustness and energy-efficient features make them a smart investment, ensuring both operational effectiveness and financial benefits over time.

Read more

The machine tool sector is growing with rise in automation: Hrishikesh B Sawant

The Indian machine tool industry is currently growing, with a number of factors contributing to its expansion.

Read more

Greaves Engineering is steadily increasing exports: Dr Arup Basu

In this interview with Rakesh Rao, Dr Arup Basu, MD, Greaves Cotton Ltd, highlights emerging trends in the Indian manufacturing sector and the company's plans for robust growth with minimum carbon f..

Read moreRelated Products

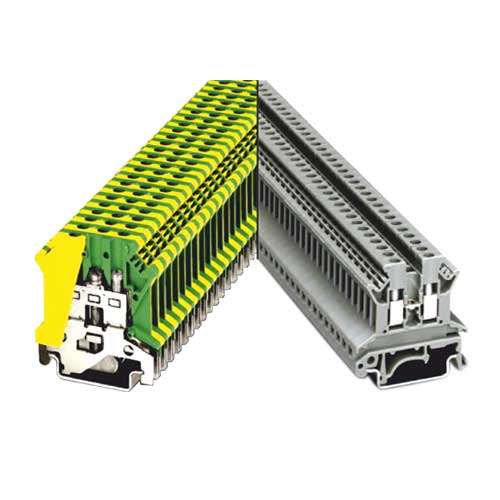

78 Series Din Rail Terminal Blocks

Werner Electric Private Limited offers a wide range of 78 series din rail terminal blocks.

Mig Welding Torches

ATE Welding Engineering Robotics & Automation offers MIG welding torches. Read more

Puma Lift Electric Stacker

Puma Lift Trucks Pvt Ltd offers a wide range of puma lift

electric stacker.